As an experienced industrial designer, especially for a mold designer, when he or she designs a plastic part, the wall thickness need to be considered carefully,On the premise of meeting the requirements of product use function and injection molding, the designers should know how to design a minimum wall thickness, because during injection molding process, The thinner the wall, the faster the part cools, so that we can save cycle times, then save part costs, of course, thinner parts weight less, for every part, we can save the amount of the plastic, in a big order, the amounts of the plastic are saved.

What is the suitable wall thicknesses of an injection-molded part? I think, generally it ranges from 2 mm to 4 mm (0.080 inch to 0.160 inch), for some plastic material, because of special requirement, The wall thicknesses can be designed as 0.5 mm (0.020 inch) without any molding problem.

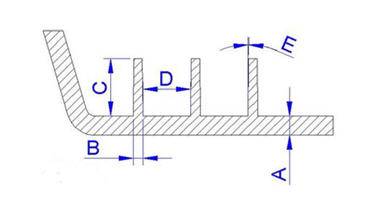

Injection molded parts can have a shell-like structure with molded surfaces and supports. Examples of these supports include walls, ribs, and gussets.

Injection molded parts can have a shell-like structure with molded surfaces and supports. Examples of these supports include walls, ribs, and gussets.

Wall thickness in injection molded parts generally ranges from 1 to 5 mm. The recommended thickness depends on the plastic material, the part’s requirements, and factors such as mold flow. For the best results, a part’s walls should be fairly consistent — that means avoiding designs with widely different walls thicknesses.

Note, however, that walls are tapered. In other words, a wall doesn’t have the exact same thickness from the base to the top. Typically, the base of the wall is slightly thicker and tapers at a draft angle of at least 0.5 degrees. Without draft, parts won’t eject cleanly from the mold and are susceptible to damage, so applying a draft angle to vertical walls and surfaces is critical.

What is the Significance of Wall Thickness in Product Design?

During product design, the significance of wall thickness is about reducing material usage while improving part quality and production speed.

Reduced Raw Material: Optimal wall thickness can reduce the amount of plastic needed and the weight of the molded part — in many cases, thicker walls can be replaced with thinner ones.

Part Quality: Designing injection molded parts with wall thickness problems can result in defects like sinkholes, warping, and short shots. These problems increase rejection rates and, ultimately, the total cost of your parts.

Production Speed: Thicker walls take longer to cool than thinner walls, but adequate cooling is critical for injection molding success. Consequently, wall thickness affects cooling rates and, ultimately, injection molding cycle times.

What is Uniform Wall Thickness?

Uniform wall thickness does not necessarily mean that every wall must have the same exact thickness. Some thickness variations are acceptable within limits. Generally, the thickness of a wall should be no less than 40% to 60% of adjacent walls because when thickness transitions aren’t gradual, part defects such as warping occur. Also, note that ribs and supporting walls do not need to be the same thickness as the main walls.

How to Design for Uniform Wall Thicknesses

Typically, injection molded parts are designed using CAD (Computer-Aided Design) software and those designs follow specific DFM (Design for Manufacturing) principles. Most modern CAD packages have a powerful set of tools with features that assist with the design of parts for injection molding. These features make it easy to modify wall thicknesses and to apply draft angles.

Selecting the Optimal Wall Thickness

For injection molding plastics, optimal wall thickness is given as a range of measurements in inches (in) and millimeters (mm). However, these numbers are a broad range — for best results, you need to work with a skilled injection molding manufacturer, like First-rate Mold Company, who can provide you with DFM feedback and insights gleaned from experience.

What is the Minimum Injection Molding Wall Thickness?

Minimum injection molding wall thickness refers to the thinnest wall recommended for a given type of plastic. There are several factors to consider when specifying this dimension. For example, it’s important to define the expected loads to which the part will be subjected — cosmetic parts are exposed to different loads than one used as a push-button. Some designers start by using the lowest possible wall thickness for the selected material, then perform a finite element analysis (FEA) using previously-defined load cases. The results of the FEA will provide a good indication of whether the thickness of the wall is sufficient. If the wall is too thin, you can adjust its thickness or select a different material. 1 mm is usually the thinnest that part walls get, although minimum wall thickness can be thinner for some materials

What is the Maximum Injection Molding Wall Thickness?

Maximum injection molding wall thickness refers to the thickest wall that is recommended for a specific type of plastic. There are several factors to consider when specifying this dimension. In general, excessively thick walls are not recommended because they often result in part defects. Sometimes, however, thicker walls are needed because of high loads exerted on the part, thermal insulation requirements, or simply to make the part feel heavier and more substantial.

Most injection moldable plastics have an upper limit which, if exceeded, can cause issues such as underfilling, warping, and excessive dimensional deviations. However, as a general rule, the maximum wall thickness should be limited to 5 mm. As with minimum wall thickness, the maximum wall thickness is a function of the plastic material being molded.

Choosing the Correct Wall Thickness for Injection Molding

Choosing the optimal wall thickness for an injection molded part can be a balancing act between part cost, strength, cycle times, and other factors. To effectively balance all of these requirements, it takes expert knowledge and real-world experience.

When you ask First-rate Mold Company for an injection molding quote, you’ll receive free DFM feedback. And, the report doesn’t merely indicate whether or not your part can be injection molded — you’ll receive recommendations about how to improve your design to accelerate production and be less expensive to mold.

The rate at which plastic parts shrink in an injection mold process depends on two major factors: the thickness of the walls and the plastic thickness of the material used. All plastic parts shrink as they cool. Therefore, the design for these plastic parts is done in such a way that this shrinking is uniform. Varying rates of shrinking lead to different defects both cosmetic and fatal. During plastic design for wall thickness, here are some rules designers take note of:

Sharp Corners

The corners of a part are very important in determining if the part will fail or not. This is because parts will sharp corners will have a high level of stress concentration. This could impede the plastic flow and cause defects on the part. To prevent this, most designers make the inside radius of a corner 0.5 times the plastic thickness while the outside radius is 1.5 times the plastic thickness.

Adjacent Wall Thickness

For adjacent walls, the thickness of one wall must not be less than 40 to 60 percent of the other. Also, both wall thicknesses have to be within the threshold for the particular material.

Draft Angles

Drafts help to facilitate the easy removal of parts from the mold. Generally, you should allow for as much draft as the plastic thickness allows. In most cases, one to two degrees of draft alongside an extra 1.5 degree per 0.25mm of the plastic thickness is sufficient. This might vary depending on the molding design on wall thickness and the part thickness.

Bosses

Guidelines for molding design on wall thickness should apply to bosses (the cylindrical structure that surrounds the opening meant for a screw). They should have a thickness of 40 to 60 percent that of the encompassing area.

Rims and Bends

The thickness of rims and bends must also be as even as possible. One way of ensuring this is to add adequate radii to the curves. This helps to ensure that the plastic material flows smoothly through the mold cavity.

Ribs

Ribs can be implemented in parts that require strength. The advantage of using ribs over thickening the part is they reduce the risk of warping. Ribs are also more cost-effective as they cool faster and require less material to produce.

Defects Caused by Uneven Wall Thickness

While injection molding provides one of the best methods for the manufacture of parts, there are still factors that can result in defects in your final product. Several defects can arise as a result of the molding process as well as the plastic thickness of the materials used. Below are highlighted some of the defects influenced by wall thickness.

Warpage

Warpage arises as a result of the uneven shrinkage of the different parts of a product. This causes twists and bends in the shape of the product on completion. As has been highlighted, uneven wall thickness causes parts of a product to cool at different rates leading to warpage.

Flow lines

Flow lines are aesthetic defects that occur on plastic products. They appear as waves or lines, usually of a different color tone from the surrounding area. They occur as a result of different flow rates of molten plastic in the mold cavity.

Sink Marks

Sink marks are like little craters formed on an injection-molded product. These craters are formed when the plastic material cannot be cooled completely while in the mold. Shrink marks are more often formed on the thicker parts of the product as they require more time to cool.

Short Shots

A short shot occurs when a part of a product is missing. This happens because the molten plastic fails to reach all the sections of the mold. Uneven wall thickness can lead to this defect. When wall thickness is uneven, plastic flowing from a thin section to a larger one can cool down prematurely. This then prevents the molten plastic from getting to the thicker section.

Why is it Important to Maintain Uniform Wall Thickness?

Appearance

Uneven wall thickness affects the aesthetics of an injection-molded part. Defects such as warping and sink marks may arise due to the uneven thickness of walls. Superficial issues like flow lines may also be noticed.

Gating challenges

Gating is done from thick sections into thinner sections. Uneven wall thickness may result in the flow of molten plastic from thin sections to thicker sections. This results in problems as the plastic material may begin cooling in the thin section, effectively blocking the flow to the thicker section. Defects like sinking and warping arise as a result of this.

Shear stress

The shear stress of the plastic in flow can be influenced by varying wall thickness. The shear stress of the flowing plastic moving at a constant rate of filling increases as the wall thickness reduces. Uneven wall thickness hence results in different degrees of shear stress. This is a major contributor to warping in plastics.

Cooling rate

Thicker sections take longer to cool. A part with uneven wall thickness will have to remain in the mold until the whole part cools off. This leads to an increase in cycle time and the overall manufacturing process.

Cost

Thicker walls require more plastic materials to fill. They also require more time to cool. More materials and a longer time on the injection molding machine will only increase the cost of production.

Plastic Product wall thickness is a critical structural feature frequently discussed and considered in the design of plastic product structures. It represents the thickness value between the outer and inner walls of a plastic part. The wall thickness is the basic parameter that determines the overall thickness of the product and is often specified during the structural design process.

Understanding the significance of wall thickness characteristics is crucial in the structural design of plastic products during mold design and the injection molding process, as it plays an important role in producing plastic items using the widely utilized injection molding method.

The outer wall of the shell part functions as the outer skin, while the inner wall acts as the structural skeleton. We can apply surface treatment to the outer wall to achieve different appearance effects. Other structures within the part, such as tendons, screws, and buckles, are connected to create strength and can be filled during injection molding. Without special requirements like heat dissipation or assembly, the inner and outer walls are typically designed as a unified whole to provide sufficient strength and protect internal parts.

For the internal parts, which often serve as bearings or connecting brackets, there are fewer strict requirements for the inner and outer walls. Based on the specific situation of the inner or outer wall, we can create structures such as reinforcements, screws, or buckles. However, in order to facilitate production and manufacturing, the outer wall is generally designed to be as simple as possible. If necessary, we can adjust to the draft angle of the cavity and core or implement designs such as ejector pins in the cavity or buckles in the core.

In both shell parts and internal parts, the wall thickness plays a crucial role in providing an ejection surface for the ejector pins, ensuring smooth ejection of the part from the mold

The flow ratio (L/T) of plastic refers to the ratio of the flow path length (L) to the wall thickness (T). It represents the relationship between the flow distance and the wall thickness in plastic injection molding.

A larger L/T ratio indicates that the plastic melt will flow further within the mold cavity for a given wall thickness. Conversely, for a given desired flow path, a larger L/T ratio allows for a smaller wall thickness. Therefore, the L/T ratio of plastic directly impacts the number and distribution of injection points in plastic products and the achievable wall thickness.

Various factors, including material temperature, mold temperature, surface finish, and other conditions, influence the calculation of the L/T ratio. The value provided is an approximate range and can vary depending on specific circumstances. While it serves as a practical reference value, precise calculations may be challenging due to the complexity and variability of injection molding processes. It is advisable to consider these factors and seek guidance from experienced professionals to determine the wall thickness in specific cases accurately.

concerning wall thickness, it is crucial for both shell and internal parts to possess sufficient strength. The ability to withstand the release force during molding is a crucial factor to consider. Typically, excessively thin parts are prone to deformation upon ejection. Generally, increasing the wall thickness enhances the part’s strength (with approximately a 33% strength increase for every 10% increase in wall thickness). However, exceeding a certain wall thickness range can result in quality issues like sink marks and porosity, diminishing the part’s strength while increasing its weight.

Consequently, this leads to longer injection molding cycles and higher material costs. Solely relying on increased wall thickness for strengthening plastic parts is not the most optimal solution. Instead, it is advisable to employ geometric features such as ribs, curves, corrugated surfaces, and reinforcements to enhance stiffness.

In situations where space and other factors do not allow for alternative approaches, the part’s strength is predominantly achieved through the appropriate wall thickness. In such cases, if strength is a critical consideration, it is recommended to determine the suitable wall thickness through mechanical simulation while adhering to the fundamental principles of formability.

In the structural design of plastic parts, the wall thickness is a critical parameter that serves as the foundation for the design. Other structures are created based on the chosen wall thickness. The wall thickness significantly affects the plastic parts’ mechanical properties, formability, appearance, and cost. Therefore, the wall thickness should be carefully considered and designed in accordance with these factors.

Regarding the meaning of wall thickness, it is mentioned that it should have a specific value. If there is only one value, it indicates a uniform wall thickness throughout the part. However, if there are multiple values, it suggests that the wall thickness is not uniform and different sections of the part have varying thicknesses. We should strive to comprehend the principles of wall thickness design to ensure the plastic part’s optimal performance and functionality.

Notice how the walls of these household items are all relatively uniform? This is one of the fundamental rules of plastic injection molding, and ignoring it can lead to sink, warp, and inaccurate or non-functional parts. Yet the functional requirements of consumer, medical, aerospace, and industrial products often leave designers little consideration for the material flow and fill properties of plastic, both of which are at least partially determined by wall thickness.

To achieve uniform wall thickness, let’s start with the basics:

Recommended wall thickness in injection molding design

Proper wall thickness will reduce the risk of cosmetic defects in plastic parts.

Walls in any plastic-molded part should be no less than 40 to 60 percent that of adjacent walls, and all should fit within recommended thickness ranges for the selected material.

Part geometries such as long unsupported spans, sharp internal corners, and poorly designed bosses (not the person in the corner office who signs paychecks), should be avoided, regardless of wall thickness.

Use ribs for strengthening tall walls where needed.

Sharp external corners are fine, but placing a radius on inside corners—part design permitting—makes them stronger and alleviates the stress that creates warp.

Bosses should follow molding design guideline rules of properly designed walls of 40-60 percent of the surrounding area to avoid sink.

Finally, follow recommendations on draft angles—1 degree of draft per 1 inch of cavity depth is a good rule of thumb—and keep draft consistent throughout the workpiece to prevent internal stresses that lead to warp and curl.

Choose Materials with Wall Thickness in Mind

One of the biggest considerations with wall thickness is which material to use for your project. With literally hundreds of materials to choose from, deciding on the right one can be challenging. You can view available resins grouped by family with recommended wall thickness ranges along with detailed information on material properties, tensile and impact strength, and maximum operating temperatures online.

While thick walls offer additional strength, there are some advantages to engineering thinner walls. In fact, the longer a production run, the more benefits that can be gained by keeping a part thin and light, so maintaining optimal wall thickness is particularly important for high-volume injection molding projects. Keeping walls as thin as possible allows for:

Resistance to warping during the cooling process

Reduced costs due to less material usage and faster manufacturing

Reduced overall weight for ease of handling, management, and shipping

Quicker cooling cycles for shorter, more efficient production run time

Wall thicknesses are not subject to any restrictions, but generally, the goal is to create the thinnest wall possible while taking into account the part’s structural requirements and overall size and geometry. The flow behavior and material qualities of the resin should also be considered.

Wall thickness is defined as the distance between one surface of the 3D model and its opposite surface. It is the required thickness that a 3D model should have. Since many 3D printing problems are caused by inappropriate wall thickness, it is important that the wall thickness of the 3D model is assigned correctly.

Maintaining uniform wall thickness allows for the most uniform flow of the plastic through the part, allowing the best processing. Also, plastics are essentially poor heat conductors. By maintaining a uniform wall thickness, the part will cool as uniformly as possible.

Determining the best wall thickness for each part is a balancing act. It must have great mechanical strength so that the part can support the intended load of any additional parts in an assembly. A good design must also prevent oddities like strength-reducing bubbles that could occur inside the wall if the part is too thick and a material that doesn’t have the proper flow properties is chosen. Any experienced design engineer with a background in plastics should be able to assist a customer with part design to avoid costly mistakes later in manufacturing.

Consistent wall thickness is critical during the cooling process in injection molding; if some sections of a part are thinner than others, the part may be vulnerable to warping, cracking, twisting, and overall failure. Uniform wall thickness minimizes both shrinkage and residual stress in the final part.

please examine an injection mold design on the computerIf completely uniform walls simply aren’t an option, gradual thickness variations are essential to maintaining design stability. Wall thickness variations in high-mold-shrinkage plastics should never exceed 10%, even with gradual transitions to accommodate for potential stress concentrations.

Uniform wall thickness also allows for the most efficient, uniform flow of resin through a tool for ideal processing. Variations in wall thickness cause molten polymers to take preferential flows, leading to air trapping, unbalanced filling, and weld lines.

yes! you are right!

thank you for you share your experiences

yes! for a plastic product design or a injection molding, This is a technical key point

Incredible points. Sound arguments. Keep up the good effort.

Hi colleagues, its fantastic paragraph regarding cultureand entirely explained, keep it up all the time.

I’d like to thank you for the efforts you have put in penning this site.

I’m hoping to see the same high-grade content from

you in the future as well. In truth, your creative writing abilities has motivated me to get my own, personal blog now ;)

Nice post. I learn something totally new and challenging on sites I stumbleupon everyday.

It’s always helpful to read content from other authors and practice

a little something from their sites.

I was wondering if you ever considered changing the page layout of your blog?

Its very well written; I love what youve got to say.

But maybe you could a little more in the way of content so people could connect with it better.

Youve got an awful lot of text for only having one or two pictures.

Maybe you could space it out better?

thanks for your great suggestion, we will consider it carefully

You can certainly see your expertise within the work you write.

The arena hopes for more passionate writers like you who are not afraid to

mention how they believe. At all times go after your heart.

Good post. I will be going through some of these issues as

well..

My brother recommended I may like this website. He was

totally right. This submit actually made my day. You can not imagine just how a lot time I had spent for this information! Thank you!

Just want to say your article is as astonishing. The clarity in your post is just great and i can assume you’re

an expert on this subject. Fine with your permission let

me to grab your RSS feed to keep updated with forthcoming

post. Thanks a million and please continue the gratifying work.

Hi, I do think this is a great web site. I stumbledupon it ;

) I am going to return yet again since I book marked it.

Money and freedom is the greatest way to change, may you be rich and continue to guide others.