FMS Prototyping Is Professional

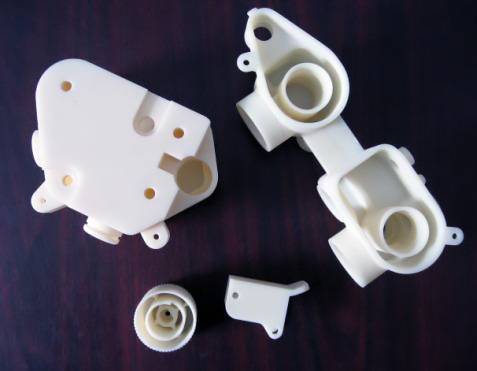

Prototyping is an indispensable step in new product development and mold manufacturing. Although 3D printing technology has increasingly entered this field, traditional prototype manufacturing is still an important means to verify the manufacturability of molds,FMS team is willing to provide cost-effective prototype manufacturing service for your new products and new molds, Our service is professional, efficient, integrity, good quality but not expensive.

We create concept models and fully detailed 3D component models for our customers. We also source rapid prototypes in SLA, 3D print and Laser Sintering for fit and function analysis where required

Prototype:

manufacturing is an important method of industrial design, which is a process to materialization of CAD model for actual experience and assessment of product, finding of design deficiency and imperfection during production, as well as optimization and correction in a timely manner.

Prototype manufacturing, first known in 1980s’, is an updated product R&D technology evolved from the integration of modern CAD/CAM technology, laser technology, computer-based CNC technology, precision servo driver technology, new material and etc, and which is a integrated systematic technology by which from part design to manufacturing of three-dimensional prototype is realized. There’re various methods and means for manufacturing prototype

Now, with improving three-dimensional printing technology, a new round of revolution will take place with prototype manufacturing and the manufacturing as a whole in the future.

Professional 3D printing service:

We offer designers and manufacturers a variety of customized 3D printing services, including high-performance prototypes, tools and manufacturing aids, end-use parts and low-volume production runs.

By applying the latest additive manufacturing technology, our team has experienced experts who are able to meet the most stringent requirements, creating your part in time, cost and precision. Whatever your needs, we can provide you with the expertise and experience in 3D printing.

Service process:

1)Upload a Model Click MAIL To Upload 2)Choose a Material 3)We 3D Print Your Model 4)We Ship Your Part

During the whole process, Our team will work with you to ensure that your 3D model can be successful completed.

3D Printing Service Technologies:

1) SLA

Stereolithography (also known as SL or SLA) builds parts layer-by-layer using a UV laser to solidify liquid photopolymer resins. It is commonly used to produce concept models, master patterns, large prototypes and investment casting patterns.

Advantages

SLA is a good general-purpose additive process for a wide range of applications. Models and prototypes are rigid, strong and durable

2)Multi Jet Fusion (MJF)

Multi Jet Fusion is a durable technology which produces medium-quality surface finish, which is ideal for high-complexity with medium accuracy and can be used for short production runs.

Advantages

MJF is ideal for enclosures, electronics housings, ducts, lattice structures, and functional assemblies. Suitable for applications that require durability such as snap fits.

3)PolyJet

The PolyJet rapid prototyping process uses high resolution ink-jet technology combined with UV curable materials to quickly and economically produce highly detailed and accurate physical prototypes.

Advantages

High accuracy, superior surface finish, and wide selection of rigid and soft (rubber-like) materials to choose from. Build multiple materials and colours in a single part.

4)FDM

Fused Deposition Modeling (FDM) creates parts layer-by-layer with engineering-grade thermoplastics. Ideal for functional parts, including prototypes, low-volume production, manufacturing aids, jigs and fixtures.

Advantages

The FDM process uses the same types of raw materials used in the injection molding process. This technology includes use of support material to create create complex parts and assemblies

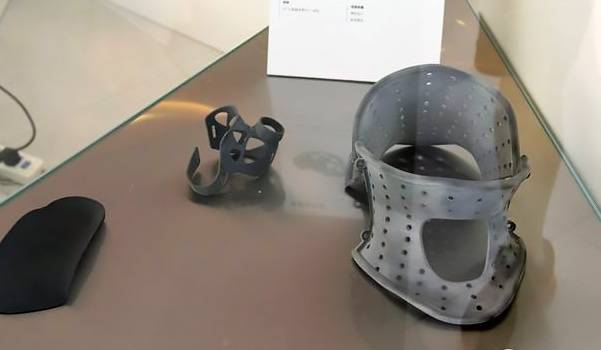

5)DMLS / Metal

Direct Metal Laser Sintering (DMLS) fuses powdered metal and alloy materials to produce metal parts. DMLS produces fully realized metal parts, including tools and end-use parts for a variety of industries.

Advantages

Metal 3D printing, with its advanced metals offering, is best utilized in highly complex and involved design

6)LS / SLS

Laser Sintering (LS) (also known as Selective Laser Sintering or SLS) uses a CO2 laser to heat and fuse durable

thermoplastic powder to build versatile parts with high elongation at break.

Advantages

LS production parts and prototypes provide lightweight, heat and chemical resistant solutions. SLS constructs 3D-printed parts from nylon (polyamide), which is strong, tough and durable

Material selection for 3D printing:

3D printed materials are very rich, including transparent, rubbery and biocompatible photopolymers, as well as tough, high performance thermoplastics and more. From fast, inexpensive concept modeling to detailed, super-realistic functional prototyping, through certification testing to agile, low-risk production, our team will help your designers and engineers solve material choice questions and make you design is successful at every stage. the following guides will help you select the perfect material based on a few important factors, like type, minimum thickness, texture and the all-important cost:

NYLON: (Polyamide)

Also called White, strong & flexible / Durable plastic / White plastic

Strong and flexible plastic, 1mm minimum wall thickness, Naturally white, but you can get it colored, About 10 layers per 1mm, Made from powder, Alumide = Polyamide + Aluminum, Interlocking, moving parts possible (chain)

ABS: (Home printers)

Strong plastic like legos are, Made from spaghetti like filament, Many color options, About 3 layers per 1mm, 1mm minimum wall thickness

RESIN: (Multiple options)

Also called White-, Black-, Transparent detail / White detail resin / High detail-, Transparent-, Paintable Resin

Rigid and a bit delicate, Liquid Photopolymer cured with UV light, White, black & transparent most typical colors, About 10 layers per 1mm, 1mm minimum wall thickness

STAINLESS STEEL:

Very strong material

Made with multiple steps or from powder directly, Coloring options like gold and bronze plating, About 6 layers per 1mm

3mm minimum wall thickness

GOLD & SILVER:

Strong materials

Made from wax and then casted, About 10 layers per 1mm, 0.5mm minimum wall thickness

TITANIUM:

Strongest material

Direct metal laser sintering, About 30 layers per 1mm, 0.2mm minimum wall thickness

CERAMIC:

Rigid & delicate

First ceramic is printed then surface is glazed, Ceramic white, glaze typically white, About 6 layers per 1mm, 3mm minimum wall thickness

GYPSUM:

Also called Sandstone / Rainbow ceramics / Multicolor

Rigid & delicateMade from powder, Naturally white, but you can get it with colors, About 10 layers per 1mm, 2mm minimum wall thickness

Before getting to the actual step-by-step making action, here’s what you will need throughout the process.

Hire an intellectual property lawyer

If you are serious about creating a killer product, you will need to protect it and make sure you’re the sole manufacturer. That’s why you’ll need a patent, and an intellectual property lawyer to make sure you get it.

Sign non-disclosure agreements with your collaborators

Anyone involved in the design, sketching, or prototyping processes should be legally responsible for not leaking any sensitive information. This information can cause you financial damages, and you have to make sure you will be fairly compensated.

Find the most cost-effective way of manufacturing a prototype

Depending on how complicated your invention is, there are a couple of ways on how to get a prototype made. You can create it yourself, collaborate with prototyping companies, or outsource the prototype manufacturing process to speed up the process and cut initial costs. We will discuss the costs of prototyping further on in this article.

Step-by-step guide on how to make a prototype

Once you’ve taken the necessary steps to protect your invention, you can start creating your 3-dimensional prototype. From market research to manufacturing, here are the X steps we recommend you follow.

Dissect the market for inspiration and flaws

First things first, you’ll need to see what’s out there in your market: who are your competitors, what are the advantages of their products, how can you make a better version, etc. Look for what your competitors do. If you like something, incorporate it into your version. If you find something you hate, be sure to stay away from it. A great way of learning from your competitors is buying their product and picking it apart to see how they make it – what solutions do they use?Make sure to get feedback from actual customers. Conduct surveys, analyze your results and in the end, create what your users dream about.

Create an initial sketch

The physical attribute of your product is one of the main selling points it will have. Be sure to create the perfect balance between aesthetically pleasing and functional. Always remember to gather feedback, listen to multiple perspectives, and modify accordingly. Here’s where putting your ideas down on paper will come in handy. It doesn’t take much effort and gives a good idea of what you want to create.

Make a digital sketch

Once you have your initial prototype on paper, it’s time to turn it into a virtual sketch. There are many tools you can use to make 2D and 3D renders of your hardware product. One of the most famous ones is AutoCAD. Further down the road, you can use other tools to create an even better model.If you are not skilled in such programs or don’t bode well with technology, you can always get the help of a graphic designer. Another option is to work with prototype manufacturing companies, and you can skip learning about the specifics of how to make a prototype.

Build it!

Once you figure out what you want, you can choose from many ways of how to get a prototype made. Here are a couple of prototype manufacturing options:- Build it yourself. If you are skilled, and building it yourself is not impossible, you can do it yourself. A 3D printer just might do the trick. You’ll get to learn all about the manufacturing process, and maybe even come up with better solutions. Plus, you’ll get to save your funds for the future.- Hire an engineer or a professional prototype designer. The pros know what they’re doing. They do it for a living and have more efficient ways of bring in your idea to life. It’s a little more costly than building it yourself, but you will probably get some amazing improvement suggestions along the way.- Advertise at an industrial design university. Students are always looking for projects to feature in their portfolio and some extra money in their student accounts, and they will require a smaller budget than a pro. This option is the most efficient one when you’re building an initial prototype. Future models may be built with more expensive materials, so it’s better to catch your flaws earlier on.

Rebuild it, and find the perfect one

Your initial prototype is obviously not going to be the final one. That’s why it’s a prototype! Don’t expect to build it and have it work perfectly (unless you’re that lucky). Be prepared to go through trial and error. Here are some questions you can ask yourself when testing a prototype:

What are 3 things you like about it?

What are 3 things you want to change?

Would you use it yourself?

Is this your best choice in the market?

Would you recommend it to friends and family?

These questions will help you organize and manage your solutions. At the end, you’ll have a product that you’re proud of and that your customers will love.

You’re almost convinced to learn how to make a prototype but need a little more? Prototyping is one of the main steps in creating a product, and it’s not a coincidence. There’s a reason that it has become a standard and even a mandatory process. It has proved itself to be effective and efficient. If you’re still debating whether to make one or not, here are some advantages to help you decide.

– It allows you to test and improve your invention

Having your prototype example in your hand will help you really see its flaws and find the best solutions to them. Then, you will be able to put it to use and see if it lives up to your vision. Little by little, you’ll perfect it and reach your final version.

– It motivates you to keep going

After thorough planning and designing, having your idea in your hands will remind you why you started it all in the first place. Reaching that milestone will excite you and motivate you to aspire for your final version and starting production.

– You’ll have something to show

Whether you’re looking for investment or getting a patent, having a prototype will give you a big boost and credibility. You’ll be able to showcase your product and prove its usefulness. In addition, it’ll be easier to sell your idea when you have something to show.

– It helps you understand the user experience

Getting feedback on a real product is easier than on an intangible idea. You’ll be able to learn about what your users really think about the physical features, as well as its usability and possible improvements.

The goal of a prototype is to ensure your design works in the hands of the user, Getting feedback on a prototype is one of the easiest and cheapest ways to get feedback, before you spend a lot of money building something that might not meet user needs. Then you’d have to spend even more to course-correct.

Creating a prototype allows design teams to hone a product concept before it’s built and launched—saving time, money, and headaches for everyone involved. Prototyping helps designers at every step of the design process, in three specific ways.

1. Validate early concepts

In a design sprint, you can bring your concept to life with a rapid prototype. This helps stakeholders align on what’s being designed, giving everyone a realistic depiction of what the experience will be.

2. Facilitate communication

Whether you’re working with clients or talking with your CEO about goals and needs, you’ve probably noticed that designers and non-designers often speak different languages. so that everyone’s on the same page—and nothing is lost in translation.

3. Refine features and flows

When you’ve designed something from the ground up, it becomes hard to see it with a fresh eye. No matter how much research you’ve incorporated into your initial design, rote data can’t replace user testing with a prototype. This will expose UX challenges that weren’t obvious during planning, and enable quick and easy changes to UI.

Prototyping offers significant cost savings—it enables the early detection of errors, allowing designers to rectify them in an efficient and cost-effective manner. Modifying a prototype is far less costly than reworking a fully developed product, as changes become increasingly expensive as the project progresses.

What’s more, the iterative nature of prototyping accelerates innovation. Designers can rapidly experiment and explore multiple ideas and quickly test and refine them based on user feedback. This iterative process fosters creativity and leads to more innovative and effective solutions.

Prototyping has many benefits and it’s recommended that you take advantage of it whenever you approach revisions or additions to your design. Here are a few of the benefits.

Prototyping clearly presents design ideas and can bring to light strong and weak design elements.

Prototyping highlights design elements that may have been accidentally omitted in the wireframing process.

Prototypes can be easily shared with your team and stakeholders, and they provide everyone the opportunity to review, experiment with, and provide feedback on the design.

Prototyping builds confidence in the success of the design. The more detail stakeholders can see and approve throughout the design process, the smoother the path to the end product will be.

Prototyping can save time and money by identifying errors or oversights early in the design process before the website or product heads into development. The later revisions take place, the more time and effort required.

Types of prototyping

There are two common types of prototyping: Low-fidelity prototyping and high-fidelity prototyping (fidelity refers to the level of detail included).

Low-Fidelity Prototyping

Low-fidelity prototypes are simple, quick, and they allow for changes and updates to be easily made. Typically done using pen and paper or with a basic online design tool, they include the bare minimum of functionality and design and allow stakeholders to see the general idea and identify specific likes or dislikes. The drawback to low-fidelity prototyping is that it is far from the actual product, and it can be difficult for some stakeholders to visualize future functionality.

High-Fidelity Prototyping

High-fidelity prototypes are far more detailed and are typically done digitally with an online design tool. These prototypes are very close to the actual finished product and include a high degree of design aesthetics and functionality. Because of the added detail, high-fidelity prototypes require more time and effort to create, and it can be more challenging to make revisions to them.

Prototyping is the process of designing a mock-up of a product or process ahead of creating a final design. Prototyping can include various stages or iterations, allowing designers, product owners, and other stakeholders to visualise how a product will look and feel, as well as how users will interact with it.

Creating prototypes at an early stage can prevent time and money being wasted on unsatisfactory designs. Prototypes can be physical, such as those made with paper or other inexpensive materials, or digital and range in the level of detail from simple wireframe designs through to more complex, interactive prototypes.

While prototyping can seem like an unnecessary delay, creating basic prototypes before mass manufacturing processes can save money in the long run. Here’s why.

Find and rectify issues before your customers experience them. If you’re designing an iPhone battery case, you might find out the battery size makes the phone unsteady when placed onto a surface. That wouldn’t be obvious if you didn’t make a prototype first.

Help with market research. Give a prototype to your target audience and gather feedback before you invest more time and money in production.

Reduce business risk. Avoid spending thousands of dollars on a product you don’t know sells or works. Get photos of a prototype before it’s available for sale and run a presale to analyze demand.

Secure investment. If you need funding for your small business, potential investors will look at a prototype to see whether your product or business is worth investing in. It’s more tangible than just a business plan.

A prototype is a preview or early sample of a product or idea you plan to invest in and eventually reproduce in large quantities. Whenever there is a new investment opportunity, before jumping to mass production and risking any capital, you’ll first need to find a way to communicate your idea to possible investors in an understandable, and many times, tangible way.

Prototypes form part of almost any industry you can think of, and they often set the ground for product testing and concept design validation. Architects, designers, engineers, filmmakers, app developers, and so many more, rely on prototypes to simulate their products and attract investors.

Ultimately, at its core, we can define it as a rapid replica of an original product or idea that can be used as a tool to gain financing investment, enhance your crowdfunding campaign, or simply set the start of the design process. Once created, they can be refined or modified to improve function or accommodate the audience’s demands.

The purpose of a prototype

As we define what a prototype model is, we can consider its main purpose to be providing a real, working sample that can be tested and evaluated for errors and efficacy, unlike a theoretical idea. A prototype model aids designers when it comes to the visualization and manufacturing of the real product.

What is typically included in a product prototype?

As a crucial part of the early investment process, prototype models oftentimes include the key aspects and features of the original idea. Given they’re often a precursor of the manufacturing process, they can oftentimes include the product’s specific color, packaging, online visuals, or navigational elements if it happens to be a website or application for example.

The key is to include anything that helps a business or potential investors make a decision. This is why it is important to devote the appropriate time and effort to make it a workable and reliable sample. If it fails to deliver, it will also testify of the original product’s abilities.

Prototypes can be quick and rough. A prototype is not usually intended to look like the final version. As long as it can be used in the early product evaluation and beginning of the design process, it doesn’t need to be perfect.

Numerous businesses have already leveraged the power of 3D printing to transform their product development process. One such example is Adidas. The renowned sportswear company used 3D printing technology to create their Futurecraft 4D shoes. By 3D printing the midsoles of the shoes, Adidas was able to customize the fit and cushioning for each individual wearer. This level of personalization would not have been possible with traditional manufacturing methods. The Futurecraft 4D shoes quickly gained popularity, highlighting the market demand for customized products. Adidas now has a whole line of mass produced running shoes with lightweight 3D printed insoles on the Carbon3D system.

Another fascinating case study is that of Local Motors, an American automotive company. Local Motors utilized 3D printing to produce the Strati, the world’s first 3D printed car. By 3D printing the car’s body and chassis, Local Motors was able to drastically reduce the manufacturing time and costs associated with traditional car production. This innovative approach to manufacturing is not only cost-effective but also environmentally friendly, as it eliminates the need for extensive material waste.

The process of turning a prototype into a final product using 3D printing involves several steps. It begins with the creation of a digital design using computer-aided design (CAD) software. This design is then converted into a file format that is compatible with 3D printing technology, such as STL or OBJ. The file is then sent to a 3D printer, which uses additive manufacturing techniques to build the product layer by layer.

During the printing process, the 3D printer deposits material, often plastic or resin, in precise locations based on the digital design. As each layer is added, the product gradually takes shape. Once the printing is complete, any support structures that were used during the printing process are removed, and the product is ready for post-processing. This may involve sanding, polishing, or painting to achieve the desired finish.

Before learning how to make a prototype, let us teach you what it is. To put it simply, a prototype is an early model of your product. Whether you are creating something brand new or improving an existing one, you’re going to need it.

The purpose of a prototype is to have a tangible product with the actual features developed during design. It brings your solutions from theory to practice. First, you’ll be testing the hypothesis of whether your product can actually be made, and second, it’ll be essential for improvement. Finally, you can learn from it, see how it performs, and perfect it until you get to your final version.

You’re almost convinced to learn how to make a prototype but need a little more? Prototyping is one of the main steps in creating a product, and it’s not a coincidence. There’s a reason that it has become a standard and even a mandatory process. It has proved itself to be effective and efficient. If you’re still debating whether to make one or not, here are some advantages to help you decide.

– It allows you to test and improve your invention

Having your prototype example in your hand will help you really see its flaws and find the best solutions to them. Then, you will be able to put it to use and see if it lives up to your vision. Little by little, you’ll perfect it and reach your final version.

– It motivates you to keep going

After thorough planning and designing, having your idea in your hands will remind you why you started it all in the first place. Reaching that milestone will excite you and motivate you to aspire for your final version and starting production.

– You’ll have something to show

Whether you’re looking for investment or getting a patent, having a prototype will give you a big boost and credibility. You’ll be able to showcase your product and prove its usefulness. In addition, it’ll be easier to sell your idea when you have something to show.

– It helps you understand the user experience

Getting feedback on a real product is easier than on an intangible idea. You’ll be able to learn about what your users really think about the physical features, as well as its usability and possible improvements.

Maybe you see the importance of not jumping into production without first having tested a product prototype, it’s time to learn how to make one. As you might imagine, this is a time-consuming but essential process, it’s not to be overlooked. These six steps will ensure you do a thorough job.

1. Start With a Product Vision

First comes the idea. You have to start somewhere. If you’re not inspired, don’t worry. Most product development doesn’t start with a lightning bolt. It’s best to begin by researching the market and competition. Brainstorming with your team is also a great way to generate ideas. But most of all, your idea should fill an unserved niche or respond to a problem that customers face.

2. Create a Sketch or Use Computer Aided Design (CAD)

Now that you have the idea, you need to get it down on paper. This can be done as a simple sketch, but more common is the use of software such as CAD, which stands for computer-aided design. It can create a 3-D replica of your product idea. That includes dimensions but also shows the product in a virtual simulation, helping you refine the product.

3. Make a Proof of Concept

Once you’ve sketched the idea, you need to create a proof of concept. That’ll show that the product can be developed and how it’ll be developed. It can also be when you test the product and explore its feasibility in a real-world scenario.

4. Make a Physical Product Prototype

Once you’ve done the due diligence and have shown that the product is viable, you’ll want to build a physical product prototype. This should be very close if not exactly like the final product that you’ll market. To do this there are a couple of common approaches. One is 3-D printing, which has become more standard and can even be used in mass production. It’s cost-effective but tends to be fragile and as yet lacks functionality. The other is CNC prototyping, which is a machine that allows for almost perfect, functional copies of a product. However, they’re expensive to install, learn to operate and maintain. A third option would be virtually simulated prototypes, but this doesn’t fit all needs.

5. Test the Prototype

Now that you have a product that you can hold in your hands you have to make sure it does what you created it to do. To validate the design decisions before mass production, you want to have real users try the product and identify issues that might arise. This way changes can be made to build a final product that meets users’ needs and expectations.

6. Create a Production-Ready Prototype

Finally, once you’re certain the product prototype is ready and all the bugs have been worked out, build a production-ready prototype that fits your budget. Figure out the materials and check with reliable vendors to determine costs. At this stage, it’s advisable to create a product roadmap to keep track of any future improvements made to your product.

The initial stages in the innovation process can be seen as leading towards the first pilot project, and during these initial stages prototyping is critical.

So, actually what is prototyping?

Let’s get back to the roots. Latin. The word prototype comes from the Latin words proto (original) and typus (model).

Prototyping seems like a simple concept until you try and define it or its fast moving friend – “rapid” prototyping. Well for a start, it’s not a pilot. That’s a good start, but this constantly expanding buzzword can lead the uninformed eye to see prototyping as everything between brainstorming and scaling when developing a solution using the process of innovation.

A prototype is an early sample, model, or release of a product built to test a concept or process or to act as a thing to be replicated or learned from.

That actually sounds pretty good. With a little bit of tweaking, Wikipedia could be on to something. How about:

A prototype is an early sample, model, or release of a product or system built to test a concept or assumption or to act as a thing to be tested and learned from.

In this sense an initial “prototype” is the first complete solution to the original challenge. The first “prototype” is the first time all parts of a solution are tested together. It is the first time that the inter-dependencies of all components can be tested, analyzed, and refined. Complete does not and should not mean final.

In conclusion, choosing the right prototyping company is crucial for the success of your product development project. Consider factors such as expertise and experience, range of services, communication and collaboration, as well as quality and timeliness when making your decision. By carefully evaluating these factors, you can select a prototyping company that will effectively bring your ideas to life.

In today’s fast-paced world, prototyping has become an essential step in product development. It allows companies to test and refine their ideas before investing in mass production. However, not all prototyping companies are created equal. To ensure the success of your project, it is crucial to choose the right prototyping company.

Expertise and Experience

When evaluating prototyping companies, one of the most important factors to consider is their expertise and experience. Look for a company that specializes in your industry or has experience working on similar projects. This ensures that they have a thorough understanding of your specific requirements and can provide valuable insights throughout the prototyping process.

Additionally, consider the company’s track record and portfolio. Look for evidence of successful projects they have completed in the past. This will give you confidence in their ability to deliver high-quality prototypes.

Range of Services

Another factor to consider is the range of services offered by the prototyping company. Different projects may require different types of prototypes – from basic mock-ups to functional prototypes – so it is crucial to choose a company that can meet your specific needs.

Ideally, look for a company that offers a comprehensive range of services, including 3D printing, CNC machining, injection molding, and more. This ensures that they have the necessary capabilities to produce prototypes using various materials and technologies.

Communication and Collaboration

Effective communication is key when working with a prototyping company. You want to choose a company that values clear and transparent communication throughout the entire process.

Consider how responsive they are during initial consultations or inquiries. Do they take the time to understand your requirements? Are they willing to provide regular progress updates? A good prototyping company should be proactive in keeping you informed about any challenges or changes during the project.

Collaboration is also important. Look for a company that encourages collaboration and values your input. They should be open to suggestions and willing to incorporate your feedback into the prototyping process.

Quality and Timeliness

Lastly, consider the quality and timeliness of the prototypes produced by the company. The purpose of prototyping is to test and refine your ideas, so it is crucial that the prototypes accurately represent your vision.

Ask for samples or examples of their previous work to assess the quality of their prototypes. Look for attention to detail, precision, and durability.

Timeliness is also important. Discuss project timelines with the prototyping company and ensure that they can deliver within your desired timeframe. Delays in prototyping can have a significant impact on product development schedules, so it is essential to choose a company that can meet your deadlines.

Why does prototyping matter?

The goal of a prototype is to ensure your design works in the hands of the user, Getting feedback on a prototype is one of the easiest and cheapest ways to get feedback, before you spend a lot of money building something that might not meet user needs. Then you’d have to spend even more to course-correct.

Creating a prototype allows design teams to hone a product concept before it’s built and launched—saving time, money, and headaches for everyone involved. Prototyping helps designers at every step of the design process, in three specific ways.

1. Validate early concepts

In a design sprint, you can bring your concept to life with a rapid prototype. This helps stakeholders align on what’s being designed, giving everyone a realistic depiction of what the experience will be.

2. Facilitate communication

Whether you’re working with clients or talking with your CEO about goals and needs, you’ve probably noticed that designers and non-designers often speak different languages. we should have commenting features to share perspectives and feedback, so that everyone’s on the same page—and nothing is lost in translation.

3. Refine features and flows

When you’ve designed something from the ground up, it becomes hard to see it with a fresh eye. No matter how much research you’ve incorporated into your initial design, rote data can’t replace user testing with a prototype. This will expose UX challenges that weren’t obvious during planning, and enable quick and easy changes to UI.

Rapid prototyping is a general term for a range of manufacturing processes that uses technology to create physical models quickly and cost-effectively. Engineers, designers, and manufacturers often use this process for prototyping new products or testing design modifications.

Rapid prototyping utilizes a digital CAD software (Computer Aided Design) design to allow for faster turnaround time between when changes are made to a design and final printing. 3D printing technology is then used to create the prototype.

It’s important to note that rapid prototyping is not the same as 3D printing. Rapid Prototyping is a broader term that involves creating prototypes using various manufacturing processes like CNC machining. 3D printing is one of the manufacturing processes used for rapid prototyping.

Using CAD software and a 3D printer, rapid prototyping can be taken to new heights. 3D printing is one of the most common prototyping methods today, simply due to its major benefits.

On the one hand, one of the largest benefits of using 3D printing for prototyping is its ability to save time and money. It does so, avoiding paying an external manufacturer for every iteration and design. Moreover, 3D printing allows designers to save the waiting time until they see a functional prototype. As a result, they can quickly make changes on the spot.

Depending on the print job, a design can be printed in a matter of minutes or hours. For particularly large models, leaving the 3D printer on overnight is the best option. It allows you to come back to the office to a fully printed prototype, freeing up space for the next one.

Furthermore, rapid prototyping allows designers to keep their concepts in-house. Therefore, not only speeds up the workflow, but it keeps ideas confidential and secure.

On the other hand, the most valuable role of 3D rapid prototyping is the ability to test and compare different models or design ideas. This applies when testing both functionality and aesthetics.

We recommend using a more durable filament like PA and TPU or a similar filament to your end-use material. This way, you can test if your design will stand up to important elements or factors, such as certain chemicals or the weather. Similarly, 3D prototyping allows you to physically compare different visual concepts and iterations.

Developing a Prototype: Step by Step

First, find products that are similar to your design. Take them apart to get an insider perspective on their function.

Using paper, draw what your idea will look like. Write or type out any additional ideas. This will give you an idea of what the first prototype will be like and will help you find flaws and other ways to improve the product’s design before you spend the time, effort, and money to build a prototype.

Hire a professional to assist you in developing a computer-aided design (CAD) of your prototype. This design will be much more detailed than your sketch and will be sent to the prototype maker to enable them to make the most detailed and accurate prototype possible.

If possible, create a handmade version of your product. Having a sample in-hand will make it much easier to discuss your parameters and ideas with the prototype maker. In addition, it will allow you to further refine your idea.

Find a prototype maker that will fit your budget. Oftentimes, making a prototype can be somewhat expensive. Decide which material you’ll use for your prototype. Prototype materials should be the same materials that you intend to use in the final product.

As you meet with prototype-making companies, inquire about their credentials and previous work to make sure that your prototype will be high quality and accurately represent your design. Regardless of whether the company has worked cooperatively with its clients in the past, obtain a nondisclosure agreement from them, unless you’ve already acquired a patent.

Consider creating a prototype with 3D printing. These printers can use CAD designs or 3D models to build a working prototype, layer by layer.

Raise funds by getting in touch with your family and friends first. You may still need to approach other sources to turn production into a reality. Investors may be especially useful during this stage.

Fulfill your customers’ orders and produce as much of your product as you can sell. Constructing a prototype can be an expensive process, so make sure to avoid getting stuck with a large inventory. As you sell your product, you’ll need to improve upon the initial design until it becomes a profitable and attractive.

Tips for Developing a Prototype

Hire a professional who is skilled at using drafting software, including CAD and its variants. Examine the design on a 3D plane and make sure the connections, angles, and balance are mathematically sound.

Don’t forget that the fewer parts a product has the better. When creating an electronic prototype, avoid redundant and ugly connections. If you’re creating a physical (non-technology-related) product, keep aesthetics and product simplicity in mind.

If you’re creating a tech product, create a list of all the necessary components. Make sure the connections and wiring are checked by a professional in the field.

Using your CAD design, make a nonfunctional, physical mock-up. Use wood, cardboard, foam, plastic, or whatever materials are similar to your intended product. While the process may be frustrating and time-consuming, it will allow you to become familiar with the physical feel of your design.

Your first prototype may not look very attractive or professional. Don’t get discouraged. Instead, check its functionality. If all works properly, then you’ll just need to refine and revise the aesthetics.

As you present the prototype to investors, include a printed and detailed guide on its assembly. Investors will find it valuable to be able to see the interior and inner workings of the product. Present both an assembled prototype and a disassembled prototype when showing your design.

You might even decide to present your prototype to your customers in order to gain feedback and suggestions. Of course, if you decide to run these tests, the judgment ultimately lies with you.

If you’re here, you likely already have an idea for a product. This might be a simple sketch on the back of a napkin, a 3D render, or even a fully-fleshed out proof of concept.

Your next step is to turn this rough idea into a functional prototype. We’ll share a process to create your own prototype below:

1. Create a detailed diagram or sketch

The first step in creating a prototype is to create a detailed concept sketch or diagram. Your objective should be to capture as many ideas as possible in a visual manner.

Ideally, you should have two concept sketches:

A design sketch showing how the product might appear upon completion

A technical sketch showing the product’s dimensions, materials, and working.

You can use software to do this, but pen and paper work better. You can even turn to these pen and paper drawings when you’re filing a patent. Feel free to experiment and be creative in this step. You’re a long way from manufacturing at this point; don’t be afraid to try new things.

2. Create a 3D model (optional)

The next (optional) step is to transfer your concept sketches to a 3D modeling software. This will help you (and any third-parties such as investors or partners) visualize the product better. You can also use this model to create a 3D printed copy of your prototype.

Another benefit of a 3D model is that you can use augmented reality apps to visualize it in the real world. This works particularly well to demonstrate the size, shape, and design of a product idea. It can be expensive for a small business that hasn’t launched yet, though.

There are a number of tools you can use to create simple 3D models.

3. Create a “proof of concept”

Now comes the fun part: actually building the product idea.

How you build your first proof of concept will depend on a number of things. If you have a simple product that you’ve already modeled in a 3D software, you can simply get it 3D printed to create your “proof of concept”.

However, if you have a complex product with a number of mechanical or electronic parts, you’ll have to improvise harder.

Remember that the proof of concept doesn’t have to look good or even resemble the final product. It simply has to work. You can even use common household products to create this early-stage model.

For more complex products, you might have to seek help from a handyman or machinist.

4. Create your first prototype

Your proof of concept shows that your product works. Your 3D model shows what it might look like.

Your next step is to combine the learnings from the proof of concept and 3D model to create your first prototype.

This should be a fairly detailed model that looks like your final product and has the same functions.

It’s not always possible to create this detailed first prototype alone. Depending on the complexity, you might want to get help from a machinist or a specialized prototype designer.

5. Create a production-ready prototype

The final step before you get to manufacturing is to trim the fat off your first prototype and get it to the production-ready state.

This is essentially a process of cost and feasibility analysis. You have to go through every part of the prototype and figure out ways to cut costs without compromising functionality.

At the same time, you should look at ways to improve the product’s aesthetics or durability.

For example, you might replace an oft-used plastic part with metal, and a little-used metal part with plastic. This will help you cut costs while still retaining quality.

It helps to work with a manufacturer and figure out how different components in the prototype might impact its cost and quality. You should also look at different raw materials and see which ones are more pleasing aesthetically.

Your goal should be to find a balance between cost and quality depending on your target customers. If you’re targeting luxury buyers, for example, quality will be more important than cost. For budget customers, it will be the opposite.

When the technology was first developed, 3D printing was so synonymous with rapid prototyping that the two terms were interchangeable. Whether referencing “3D printing,” “rapid prototyping,” or “RP,” the conversation generally all referred to the same thing. Today, 3D printing has developed into end-use production capabilities as well and is more commonly synonymous with “additive manufacturing.”

Still, rapid prototyping was the first and remains the largest application for 3D printing. Iterations from proof-of-concept through to functional prototype can all be 3D printed. Whether outsourced or in-house, using 3D printers speeds up the rapid prototyping significantly through removing traditional bottlenecks in tooling and/or shipping. Rapid prototyping can also increasingly be done using the same 3D printing technology as will be used for the final product.

One of the biggest challenges in creating a prototype is balancing utility and cost. You want the product to fulfill its promised functions, but you also want to sell it at a reasonable price. An exceptional product that your customers can’t afford is bound to fail.

At every stage in the design process, ask yourself two questions:

Is this part necessary?

If yes, what is the cheapest material to make it without sacrificing utility?

The cost of materials varies widely, even among materials in the same category (such as “plastic” or “metal”). Keep this in mind when you’re designing your product.

Another reason for cost overruns between prototype to final product is the use of custom manufacturing techniques.

Essentially, any factory that builds your product will use some industry standard manufacturing processes (such as “injection moulding”). If your product can’t be manufactured using them, the factory will have to create customized techniques and train its staff to use them.

This can add substantially to the production cost, especially if you’re manufacturing in small batches.

Therefore, when you’re designing your prototype, keep a close eye on the kind of manufacturing process each part will require. If a feature requires a heavily customized production technique, consider removing it. A prototype designer or machinist should be able to help you figure this out.

Related: What Your Business Plan Should Look Like: Sample

Taking apart your competitors’ products can give you a detailed understanding of what works, what doesn’t when making a product. This can be a massive help in designing your own idea.

Therefore, before you start creating your prototype, take a close look at your competitors’ products. Analyze their materials, design, and manufacturing techniques. Look for flaws and opportunities.

Testing a prototype is an essential part of creating a product. It’ll help you identify weak spots in your prototype and avoid going over a budget: it’s cheaper to fix a prototype than a final product. Not to mention, you’ll get valuable insights from real people and improve your product to avoid negative feedback after you launch it.

To me, prototypes are VERY rough. I wouldn’t expect either the assets or the code to be shippable or consumer facing at all. In that sense, the protoype you build will probably just be used to convey your idea. If you’re using the prototype just to help sell your idea, then you should be fine.

If you consider the prototype to be something shippable, then yes, you definitely need to either get permission, license, beg, bribe, etc. to make sure you’re covered for your intent to sell.

Will 3D Printing Ever Replace traditional Prototyping? It’s a fair question when you consider how quickly it has already revolutionized the industry.

Potentially, many, many years from now 3D printing will expand to replace traditional manufacturing as we know it today. However, this is not likely something we will see in our lifetimes. In the near future, 3D printing could potentially significantly modify some processes within the industry.

Rather than seeing 3D printing as a potential ender of manufacturing as we know it, we see 3D printing as a way to expand the field of manufacturing beyond what we can currently even imagine.

Whether you’re a small business owner or part of an international conglomerate, it’s wise to include a design prototype in your business plan. Here’s why:

A prototype will help you understand the user experience. When you have a physical product in hand, you can comprehend the prototype design in a way that isn’t possible if it’s just a theoretical idea written out in an inventor’s journal.

A prototype facilitates market research. When you present a potential consumer with a visual prototype or place a physical object in their hands, you can use their reactions to glean information about your target audience.

A prototype improves your final design. Remember that your prototype is just a passing stage in the overall production process. To reach the next level of success, you’ll need to identify flaws in the prototype, and put in some hard work to remedy those flaws.

A prototype can spark other invention ideas. Let’s say you’re working on a prototype for a remote control car, and in the testing process you realize the car should be controlled by a mobile app. Suddenly, you have to hire iOS and Android coders, but more importantly, you’ve identified an additional product that should exist.

Creating prototypes isn’t difficult and here are some general steps involved in the prototyping process:

Define your requirements

The first step of prototyping is to define your goals – why do you need a prototype? What are you trying to solve?

Ideation

Once you have your goals, jump in and create as many prototyping ideas, don’t get bogged down in this step, as these ideas will help jog your mind to think outside the box no matter how silly they may be, it’s always an important process.

Build your prototype

In this phase, you will design an actual prototype based on the information gathered from the quick designs. This will be a small working model of your requirements.

User testing

Once you’ve created a prototype, you’ll need to put it in front of users. You’ll want to observe how they interact with the product in its current state and ask for feedback on the experience. By continuously prototyping, you’ll be able to make informed design decisions that will help you iterate your way to an intuitive and user-friendly product that users will love.

Refining prototype

Based on the user’s feedback and suggestions, this will be the stage to refine your prototype. This phase won’t be over until all the requirements you specified at the beginning of this process have been met and the user is happy with the results.

Practical tips that work for any prototype

First and foremost, all prototypes should be catered to the audience they’re being made for—this ensures relevant, actionable results.

Whoever the audience is should also be primed, prepared, and given background knowledge to avoid confusion. It is important to involve them in the design process. After all, user feedback is the lifeblood of any successful prototype.

Prototyping is an integral part of Design Thinking and User Experience design in general because it allows us to test our ideas quickly and improve on them in an equally timely fashion. The Institute of Design at Stanford (d.school) encourages a “bias towards action”, where building and testing is valued over thinking and meeting. However, why is prototyping so important in the design process? Moreover, how does it help you create human-centred design solutions? Before we start making prototypes to test our assumptions, we should get a closer understanding behind the what, how and why of prototyping at first.

we should know the important Role of Prototyping in Design, In some cases, with the help of a competent layout of the site, you can persuade visitors to certain actions. The prototype is an important draft design that precedes the development of the original design layout, and prototyping is a process designed to significantly reduce the time to develop a site.

Here are the reasons why prototyping is important in design:

The prototype gives the customer a complete idea of how the site will look like in the final result.

Prototyping allows you to streamline the design development process, focusing on important interface elements.

A site’s sketch is an irreplaceable thing if the client still does not fully understand what he expects from the site, what functions each page will carry. Careful planning at the prototyping stage makes it possible to avoid global changes in the finished layout.

At the prototyping stage, it is possible to identify unnecessary elements that are best abandoned.

This process significantly reduces the workload of the designer in developing the project, and thus saves the customer money.

Having a prototype in hand, the designer and customer more clearly represent the final result.

3D printing is gradually replacing traditional prototype making

Prototyping not only presents a strong visualisation of the design to understand the look and feel of the final product but it also helps the team to comprehend better why they are designing, what they are designing and for whom they are designing.

One of the most important aspect of product building process is to gather feedback. With prototyping you can collect reviews at every stage of developing the product — whether adding new features or redesigning parts of the product. Test what is working for the audience and what is not. Define goals with your team members, the management teams, external stakeholders, SMEs etc. and come to the best collective decision.

The first step toward turning your idea into reality is getting it down on paper. Draw your idea to help you visualize your prototype in greater detail. While it is possible to use a digital drawing program for this step, it may be more efficient to start on paper first. For one thing, in the early stages of creating your prototype, you’ll have a lot of ideas running through your mind and competing with each other. You’ll save time by drawing these rapidly on paper instead of investing time perfecting a digital drawing.

Keep a sketch notebook to provide documentation that can be used when submitting your patent. It also may come in handy if you ever need to defend your ownership of your intellectual property.

At some point it’s going to be invaluable to create a digital sketch of your idea. A standard digital design tool used by engineers and other professionals is AutoCAD, which enables them to make both 2-D and 3-D renderings.

A 3-D rendering lets you rotate and animate your virtual sketch, so you can visualize it from all angles. Tools such as NVIDIA Iray, CATIA Live Rendering and Quadro can further enable you to transform your 3-D drawing into a photorealistic prototype, helping you see approximately how a physical version of your design will look. If you’re not skilled with computer drawing and rendering tools, professional graphic designers or prototype designers can assist you with this step.

3D printing is replacing traditional prototyping

A prototype is an early sample, model, or version of a product built to test a concept or process, or used as something to copy or learn. It is a term used in a variety of environments, including semantics, design, electronics, and software programming. Prototypes are often used to evaluate new designs to improve the accuracy of system analysts and users

In terms of materials, the materials that will be used for the final product may be expensive or difficult to manufacture, so the prototype may be made of a different material than the final product. In some cases, the final production material itself may still be under development and not yet used in the prototype.

Large-scale production processes are often not suitable for manufacturing small parts, so prototypes may use a different manufacturing process than the final product. For example, the final product will be injection molded from plastic and will require expensive custom tools, so the prototype of the product can be made by machining or three-dimensional engraving. Differences in the manufacturing process can result in differences in the appearance of the prototype and the final product.

The final product may undergo a series of quality assurance tests to verify compliance with drawings or specifications. These tests may include custom inspection fixtures, statistical sampling methods, and other techniques suitable for the ongoing production of a large number of end products. Prototypes are usually passed through more careful personal inspections and assumptions, and some adjustments or rework will be part of the manufacturing process. The prototype can also dispense with some requirements that apply to the final product.

I was curious if you ever thought of changing the page layout of your website?

Its very well written; I love what youve got to say.

But maybe you could a little more in the way of content so people could connect with it better.

Youve got an awful lot of text for only having 1 or 2

pictures. Maybe you could space it out better?

Thanks for your advice! We will take your suggestion into serious consideration

At least for now, 3D printing is unlikely to replace the traditional prototyping completely, because of material

I totally agree, because 3D printing is not good enough for functional samples,Poor mechanical properties

At least for now, 3D printing is not a complete replacement for traditional prototyping

Many 3D printing devices and materials do not fully meet the design requirements, which means that it will take some time for 3D printing to be truly applied in actual product development

There is no denying that 3D printing technology has entered the field of prototype manufacturing. In the near future, it will replace traditional prototyping

In fact, 3D printing technology has become more and more mature, and traditional prototyping technology will be eliminated

At present, 3D printing technology is gradually replacing the traditional prototyping technology.

I still think 3D printing will replace traditional prototyping

3D printing should replace prototyping in the near future

3D printing is developing rapidly and will replace prototype manufacturing in the near future

I think in the future 3D printing will replace traditional prototyping

your prototyping idea is still correct,3D printing is difficult to fully replace the traditional prototype manufacturing technology

Your technology is still the traditional prototype manufacturing technology

we still do like this, at present, no problem

3D printing challenges traditional prototyping techniques

I think 3D print is a new technology for our manufacturing industry, in the future, it will change our manufacturing concept

3D printing is challenging the traditional prototype manufacturing

3D printing is still not a substitute for traditional prototypes

We still use traditional prototyping technique

3D print technology is more and more popular in prototyping

at present, troditional prototyping technology is still needed in our industry

I still say at present 3 d printing is hard to completely replace the traditional prototype manufacturing technology

3 d printing technology is still immature.

3 d printing technology is not mature enough, so traditional prototyping technology is still used

prototyping technology is still needed in many professional companies

our company is still using traditional prototyping technology

this is an important process for a new product development

Prototyping is still needed in industrial design

at present,we still need traditional prototyping technology

at present prototyping technology is still very important for our new product development

we also need prototyping for our new products, if you provide that kind of service before you make mold for us, we can decide to build business relationship with you

yes! we can provide that kind of service for your new products

now 3D printing still does not replace the prototype manufacturing

At present we still need the prototype manufacturing

Prototyping are still needed in our new product developing engineering

Prototyping is being replaced

I agree the saying about 3D print will replace prototyping industry

you porvide prototyping for your customers is a professional service

3D print is going into this industry, maybe it will become a new industry

your process will help your customers a lot.

3D print will be the mainstream in this industry

3D print is more and more popular in this industry.

3D print is replacing this field

3D print will help you a lot:-)

3D print will help prototyping a lot,Even will replace it。

yes! this is an important process for a new product

It’s fantastic that we got something useful from this article

you have rich experience in this field, but 3D print will help your job!

Maybe 3D print will help your design a lot

3D print will change your idea

I have to say you are an expert in your industry

we need to make prototypes for my new product, now 3D printing can not substitute for the traditional manufacturing technology

I think this is a good new for your customers

I absolutely love your blog, your company is very professional

you understanding for prototype is very well

Wonderful article! That is the type of info that should be shared around the internet.

in my opinion, at least in our company, the prototyping from 3D printing can not match our requirement

we still need traditional prototype making technology

That is very attention-grabbing, You’re an excessively skilled blogger.

I have joined your feed and look ahead to seeking more of your magnificent post.

Also, I have shared your website in my social networks

you have a good understanding in prototyping

3D print will help prototyping

It’s hard to find experienced people on this subject, your service is very professional

3 d printing is coming into our lives

I think 3D print is a good new for prototyping. in the future, I am not sure if we still need mold industry

prototyping is very important, it can help you to find out some design issues!

3D print will help prototyping

we still need prototyping for our new product.

sometimes Prototyping need some special production methods

prototyping is an important step for a new product development

prototyping is very important for a new product design

We are a professional manufacturer of prototype, maybe we can discuss here.

The prototype of the traditional manufacturing technology is still mainstream

it seems that you provide prototyping service for your customers! that is a good ideal

I think every industrial designer always needs prototype sample for his new design

3D printing needs to improve, otherwise It is not very practical

you can avoid a lot of mistakes if you make a prototype before making a mould

our company also privoides prototyping service for our customers

New product development still needs prototype manufacturing

we provide that kind of service, if you have any need in prototyping, please feel free to contact us

I think you provide such services to your customers is very well.

At least for now, prototyping is an essential process for a new product development

3 D print will change our understanding in prototyping

Many design firms will choose your company, one-stop service is very important

Whether to use 3 d printing or traditional manufacturing, the prototype of every new product development is very important

We are an outdoor products manufacturer, each of our new product always need some prototypes

Our prototype manufacturing technology is very good,If you need our service, please feel free to contact us

Prototyping is a very mportant process for developing a new product

I still want to say:” At present, 3 d printing can’t replace our traditional prototyping”

3 d printing material is limiting the development of 3 d printing

We are a professional prototype manufacturer, if there is any demand, please contact

3 d printing completely replace our traditional prototyping also need a long time

as an industrial designer, I want to say, Prototyping is very important

3 d printing is coming into this field, in the future, I am not sure if it could replace our mold industry

Yes!We are still using traditional methods of prototype manufacturing to serve our customers

The current 3 d printing technology is still difficult to replace the traditional prototyping technology

all kind of traditional prototyping methods are still our mainstream

You still use those traditional prototyping methods

Now 3D printing technology has been used to print many prototypes

I’m excited to discover this website.Have you invested 3 d printing equipment?

we are planning it, thanks for your attention

3 d printing has been more and more used in prototyping

Before making moulds for your new product, we have to do some prototypes for it

it seems that your company is a very professional company in mold engineering

Prototyping can find a lot of manufacturing problems for product design

before making mold, the prototype making is the right thing to do

3 D printing are moving into this area, but The current prototype manufacturing technology is still needed

now We are still using traditional methods of prototyping to serve for our customers.

At least for now, we still need prototyping. hi! We are a prototype manufacturer.We are willing to serve for you

The appearance of 3D printing will change our understanding of the prototype

Hi, we are a supplier of 3D printer, maybe we can update your concept.

In the development of a new product, prototype manufacturing is needed

We are a prototype manufacturer, what can we do for you?

3D printing is more and more popular, please pay your attention

Hi, the design and layout of this website are truly nice and I am very pleased to know that the prototype manufacture is still needed in our mold industry. thanks!

You seem to understand all kind of prototyping method.

our company focus on prototyping, maybe we can help you to do some projects.If you have any need, please feel free to contact us.

Thanks for telling me Prototyping is still needed in our product development, 3D printing needs to improve it’s technology

No doubt,we still need prototyping in our product development, 3D printing technology is still not perfect

Before 3D printing, Prototyping had been popular for many years,For the moment,The vast majority of companies still need prototyping for their new products。 because 3D printing is too expensive.

What a coincidence, now I have some new products need to make prototypes, maybe you could help me

I have read so many posts regarding mold technology, but this piece of writing

is genuinely a good post, keep it up. we also provide prototyping making service, if you are interested in it, we can discuss something together.

Terrific article! That is the kind of info that are meant to

be shared around the internet. Prototyping making is a very important process in product design. first-rate mold solution limited company provides that kind of service, that mean this is a professional company

Hi! This is my first visit to your blog! now We are starting a new project .

Your blog provided us valuable information to work on. You have done a wonderful job!

A well written article, Prototyping making is a very important process for product design, now 3D printing is more and more popular,but at present, in my opinion, it is just only supplementary means of Prototyping making

Hi colleagues, useful and professional post and interesting arguments

I leave comment at this place in order to support you, I am a mold designer, I will share something useful here

I am glad to know first-rate mold solution limited company also provide prototyping making service, I think in the future, we can discuss some cases here, maybe we can learn each other

Outstanding post, you have stated some excellent details,

I believe this is a good web site. I will recommend to my friends.

Howdy! Do you use Twitter? I’d like to follow you if that would be okay.

I’m absolutely enjoying your blog and look forward to new

posts.

we do have Twitter account, please let us know your Twitter account

Excellent post. I was checking continuously this blog and I’m

impressed! Extremely useful information specifically the

last part :) I care for such info much. I was looking for

this certain information for a very long time. Thank you and good luck.

I feel that is one of the most important info for me.

And i’m happy studying your article. But want to remark on some general issues, The site taste is wonderful,

the articles is truly nice : D. Excellent activity, cheers

Hi, I do think this is an excellent site. I am glad to see it ;) I will come back once again since I bookmarked it.

Money and freedom is the best way to change, may you be rich and continue to help

others. thanks! first-rate mold limited company

This is a topic which is close to my heart… Best wishes!

Where are your contact details though?

great website, excellent blog! many many professional peoples will love it, I should recommend it to all the peoples who need to make molds, also I find some products in this online store in this website, that is a great ideal!

I’m more tɦɑn happy to uncover this site. I newd to tο thank yοu foг yoսr time jusst for this wonderful reaԁ!!

I definitelƴ enjoyed evеry paгt οf it and i аlso Һave you book-marked tߋ seee new inforation oon үour webb site.

If you are going for most excellent contents like me, only pay a

quick visit this website all the time as it provides quality contents, thanks

hello!,I love your writing very so much! proportion we keep up a correspondence extra approximately your article on AOL?

I require an expert in this house to unravel my problem.

May be that’s you! Taking a look ahead to peer you.

Incredible points. Sound arguments. Keep up the great spirit.

Hello friends, good piece of writing and nice

arguments commented at this place, I am in fact

enjoying by these.

Hello There. I found your weblog the use of msn. This is an extremely neatly

written article. I’ll be sure to bookmark it and come back to learn extra of your helpful info.

Thanks for the post. I will certainly comeback.

Hello, I rezd ʏouг neԝ stuff regularly. Үoսr story-telling style is awesome, ҝeep dοing what you’re ɗoing!

Now, more and more prototype manufacturing technology has been applied

We are a group of volunteers and starting a new scheme in our community.

Your web site provided us with valuable info to work on. You’ve done a formidable

job and our whole community will be thankful to you.

Admiring the time and effort you put into your blog and in depth information you provide.

It’s nice to come across a blog every once in a while that

isn’t the same old rehashed material. Great read!

I’ve bookmarked your site and I’m including your RSS feeds to my Google account.

I used to be able to find good information from

your content.

Keep on writing, great job!

Hey there! I’ve been reading your website for some time now and finally got the bravery to go ahead and give you a shout out from New Caney Texas!

Just wanted to tell you keep up the good job!

Hi, just wanted to tell you, I enjoyed this blog post. It was

funny. Keep on posting!

I’m really impressed with your writing skills as well as with

the layout on your blog. Is this a paid theme or did you customize it yourself?

Anyway keep up the excellent quality writing, it’s rare to see a great

blog like this one nowadays.

I am regular reader, how are you everybody? This paragraph posted at this web

site is really fastidious.

Hi there Dear, are you actually visiting this web site on a regular basis, if so then you will without doubt get fastidious

know-how.

Hi, for all time i used to check weblog posts here in the early hours in the dawn, as i

like to learn more and more.

Good day! I could have sworn I’ve been to this

site before but after looking at a few of the posts I realized it’s

new to me. Anyhow, I’m definitely delighted I found

it and I’ll be book-marking it and checking back regularly!

Amazing! This blog looks exactly like my old one! It’s

on a entirely different topic but it has pretty much the same page layout and design. Outstanding choice of colors!

Greetings! Very helpful advice in this particular article! It is the little changes which will make

the greatest changes. Thanks a lot for sharing!

hey there and thank you for your information – I have definitely picked up something new from right here.

I did however expertise some technical issues using this

web site, as I experienced to reload the website many times previous to I could get it

to load correctly. I had been wondering if your web host is OK?

Not that I’m complaining, but slow loading instances times

will often affect your placement in google and could damage your quality score if advertising and

marketing with Adwords. Well I’m adding this

RSS to my e-mail and can look out for much

more of your respective interesting content. Make sure you update this again soon.

hello!,I love your writing very much! percentage we keep in touch extra approximately your post on AOL?

I require a specialist in this area to solve my

problem. Maybe that’s you! Looking ahead to peer you.

Great beat ! I would like to apprentice whilst you amend your web site,

how could i subscribe for a blog site? The account helped me a applicable

deal. I have been a little bit familiar of this your broadcast offered vivid clear idea

Asking questions are actually nice thing if you are not understanding

anything entirely, however this piece of writing gives fastidious understanding

even.

My brother recommended I would possibly like this website.

He was totally right. This post actually made my day.

You can not imagine just how much time I had spent for this information! Thanks!

Pretty section of content. I just stumbled upon your site and in accession capital to assert that

I acquire actually enjoyed account your blog posts.

Anyway I will be subscribing to your augment

and even I achievement you access consistently quickly.

Excellent goods from you, man. I’ve understand your stuff previous to and you are just extremely wonderful.

I really like what you have acquired here, certainly like what you’re saying and the way in which you

say it. You make it entertaining and you still take care

of to keep it wise. I cant wait to read much more from you.

This is actually a terrific site.

Way cool! Some extremely valid points! I appreciate you penning

this post plus the rest of the website is also very good.

Hi, i think that i saw you visited my website so i

came to “return the favor”.I am attempting to

find things to improve my website!I suppose its ok

to use a few of your ideas!!

Way cool! Some very valid points! I appreciate you penning this write-up and

the rest of the site is very good.

Thanks in support of sharing such a nice opinion, piece of writing is good, thats why i have read it entirely

Hi there to every one, the contents existing at this site are genuinely awesome

for people experience, well, keep up the good work fellows.

We have gone ahead and included a link back to your internet site from one of my clients requesting

it. We have used your blog URL: //firstratemold.com/services/c18-services/prototyping/ and blog title: Prototyping – Professional industrial design services, High value-added mold and High quality product

suppliers to ensure you get the correct anchor text. If you

woud like to check out where your link has been placed, please email me at: [email protected].

Thanks a lot

Wow, amazing blog layout! How long have you been blogging for?

you make blogging look easy. The overall look of

your website is fantastic, let alone the content!