The Importance Of Plastic Product Design

Plastic products occupy a very important position in the entire manufacturing industry, their molds account for almost 40% of the entire mold industry, and their advantages are also very obvious.

However, the design of plastic products has their own unique requirements and rules. It must be completed by professional designer. Based on decades of experience in the plastic molding industry, FMS design team will benefit your products.

However, the design of plastic products has their own unique requirements and rules. It must be completed by professional designer. Based on decades of experience in the plastic molding industry, FMS design team will benefit your products.

Collaborative Product Design: Now we have achieved Collaborative product design through the Internet. You can discuss our designs online with us at any time, analyze and assemble prototypes together. It’s like we designed the product with you. Our customers are very satisfied.

Advantages Of FMS Plastic Product Design

FMS product designers have unique advantages in the design of plastic products, at first, Our experience in injection molding simulation analysis and injection mold design benefits our plastic product design. secondly, We are located in the most concentrated area of injection mold making and injection molding production in the world. it allows us to access all kinds of mold makers and injection molding companies, and expose us to new designs and molding techniques. these also benefit our plastic product designers, Our service is professional, efficient, integrity, good quality but not expensive.

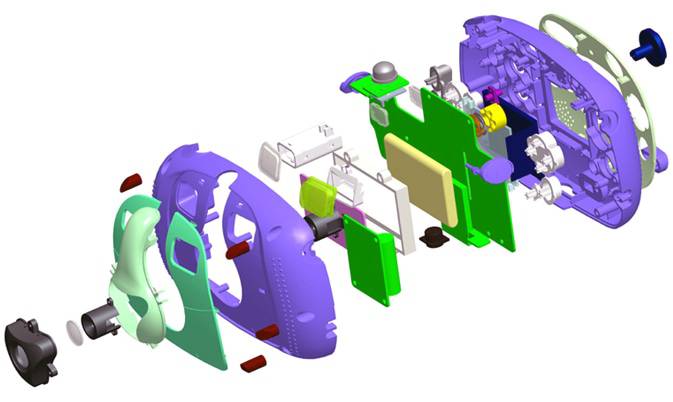

Injection molded plastic products can be designed to provide good looking products that consumers want to buy at no additional cost over boring products that have no sales appeal. To do this, you need the right product concept, the right people, and the right tools. Almost all of the new products on the market today are designed using industrial strength solid modeling CAD systems with good surface modeling capabilities such as UGNX. Our experience in UGNX surface modeling gives us the skills and tools we need to create competitively priced parts designed for economical injection molding.

Just the right tools are not enough to create good looking parts. A designer with a sense of style who is working with an strong look concept is required to deliver a product look that will sell. Our experience in creating attractive plastic parts in UGNX can help you turn the idea of a good product into the physical reality of a well-designed plastic product.

Productive Design

Parts made of plastic must be “designed for production” than any other material. Almost everyone can design a plastic product to a certain extent, but in order to do it well, in addition to the “conventional” design skills, you need to understand the injection molding process and the function of the injection mold. We have previously provided our customers with the services of our injection mold design, and we have a deeper understanding of injection molds and injection molding issues. This knowledge, combined with our UGNX and FEA stress analysis capabilities, provides us with a powerful background in the design of plastic products.

The importance of plastic stress analysis

The importance of plastic stress analysis

The structural characteristics of plastic are very different from those metals, which is no longer news. But even a common term like stress, the meaning of a plastic part is very different from the meaning of a metal part. The real question is how do these different material properties affect the design process?

Plastics are considered to be a low cost material, but in reality they are quite expensive from a unit volume or load bearing point of view. Due to the high speed of the injection molding process, the cost of plastic parts is low. With this in mind, 100% of plastic products are not always the best way to get the most cost-effective products.

Plastics are generally good at handling intermittent loads, but they are permanently deformed even at low long-term loads. Often, a reasonable amount of plastic can not be added to overcome this characteristic in the design, so adding a small amount of load bearing metal parts to the main plastic design will result in a better product.

Understanding of Plastic Product Design and Development?

Plastic Product design and development related to designing new products from plastics. They are a modern process that involves the following steps: Concept, design, and production. This involves aspects such as the choice of materials, adherence to design theories, and manufacturing requirements in coming up with products that suit a certain user need or market demand.

Different Types of Processes Used in Plastic Product Design and Development

Here are some of the common types of processes we can use for plastic product design and development;

1. Injection Molding

This method of molding plastics is one of the most frequently used technologies for creating parts for mass production. It is a process by which a desired shape is created by pouring a heated liquid material which is plastic in this case under a high-pressure chamber and appears in the plastic injection mold in a desired shape already created. In another case when the plastic remains hot, the mold opens and releases the part but the final shape remains that which is intended. It is a highly efficient technique for volume production because the process is fast, and parts can be produced with close tolerances and very little material being used up.

2. Blow Molding

Blow molding is particularly applied for the manufacturing of hollow products made of plastic materials such as bottles and containers. The first step involves softening the plastic using heat and then pouring it on a mold. Air is then forced into the mold, and the molten plastic is forced into the hollow shape of the inner surface of the mold. When it comes to the idea that blow molding is good for products that have to be lightweight, resistant to impact, and should have the ability to contain a liquid.

3. Thermoforming

It is mainly comprised of heating a plastic sheet and transforming it into a flexible form of plastic. The material is then draped over the mold and via a vacuum-forming process is drawn over the surface of the mold and leaves when the material cools. Thermoforming is more widely applied in the packaging industry, disposable trays, and containers. So, this method is characterized by relatively low costs and allows the creation of thin light products in large quantities.

4. Rotational Molding

Rotational molding or roto-molding is a slower method of molding that is more appropriate for producing large empty articles such as tanks, playing equipment, and boats such as kayaks. Here, powdered plastic is put into a mold that is then heated and is also compounded on a two-plane system. As the mold rotates the powder melts and the bonding of the powder to the interior walls of a mold is done providing a strong product without seams. It is suitable for the generation of an extensive and rather thin-walled container including varying wall thickness.

5. 3D Printing

3D printing or Additive manufacturing process involves the construction of an object using a physical model created from a computer source. While most other technologies are removal- or casting-based, 3D printing enables direct control of intricate surface geometries and voids. Because it can make a physical model of the design without the use of the costly mold, it is frequently used for prototyping. It is also appropriate to use if a production run is small or on assemblies that require specific materials.

Designing a plastic part for manufacturability involves many important factors that touch on all areas of part design, tooling, material selection and production. First, it is essential to build parts around functional needs by keeping design intent or the end use in mind. Consider weight reductions, the elimination of fabrication and assembly steps, improving structural components, reducing costs and getting products to market quicker. Here are 8 important factors to consider to meet your plastic part design goals for a successful production process.

1. Material Considerations

Manufacturers often select a familiar grade of plastic from a similar application or rely on recommendations from suppliers. Resins chosen this way may be adequate, but are rarely optimal. Plastic selection is a complex task that involves many considerations, such as:

Temperature: Thermal stress that may occur during normal and extreme use conditions, as well as during assembly, finishing and shipping.

Chemical resistance: The effects that occur when any solid, liquid or gas come in contact with the part.

Agency approvals: Governmental and private standards for properties such as heat resistance, flammability, and electrical and mechanical capabilities.

Assembly: The plastic’s cooperation with all assembly steps like bonding, mechanical fasteners and welding.

Finish: The material’s ability to produce the desired finish such as gloss, smoothness and other appearance values as it comes from the mold.

Cost: Resin pricing as well as the cost calculations for manufacturing, maintenance, assembly and disassembly to reduce labor, tooling, finishing and other costs.

Availability: The resin’s availability in regard to amount needed for production.

2. Radius

Radius should always be a consideration in regard to the part’s thickness – eliminating the likelihood of areas of high stress and possible breakage of the part. A general rule of thumb is that the thickness at a corner should be in the range of 0.9 times the nominal thickness to 1.2 the nominal thickness of the part.

3. Wall Thickness

Designing your part so that wall thickness is consistent can help avoid many part defects that can occur during the manufacturing process. When plastic melts, it flows to the areas of leas resistance. If your part has inconsistent thicknesses throughout, the melt may flow into the thick areas first (depending on gate locations). When this occurs, the thin areas may not fill properly. Additionally, thicker areas tend to cool more slowly and are at risk for voids or sinking defects. Designing your part with rounded corners will also aid in the proper filling of the part during the molding process.

4. Gate Location

Gates are critical to ensuring the resin flows properly into the mold. These small components of your design are what directs the flow of resin from the runners to then be distributed through the part. Type of gate and placement has an important impact on the part’s overall quality and viability.

5. Draft

Draft is the amount of taper on the vertical walls of the plastic part. Without draft, a part may not eject from the mold, or may sustain damage during ejection. Typically, draft angles between 1° and 2° are required, but can vary depending on part restrictions and specifications.

6. Inclusion of Ribs

A plastic part that has been designed with a minimal wall thickness will not be as strong as a thicker part – which is why the inclusion of ribs may be needed to help reinforce the part’s strength. Depending on the material used, rib thickness should be between 50 – 70 percent of the relative part thickness to avoid sink marks. To avoid sinking, designers may core out material to reduce defect risk.

7. Mold Shrinkage

The shrinkage that occurs during the plastic part molding process can be as much as 20 percent by volume. Crystalline and semi-crystalline materials are most prone to thermal shrinkage. Amorphous materials are known to shrink less. Here are a few easy ways to avoid molding shrinkage issues:

Adjust the formulation

Adjust the mold design to get the dimension you want based on the expected shrinkage that will occur

Optimize the processing parameter such as molding temperature, melt temperature, and injection speed/pressure/time, cooling time.

8. Special Features

Plastic parts should be designed so that mold tools open and eject the part easily. When a part is released, the two sides of an injection mold separate in the opposite direction. When special features like holes, undercuts or shoulders prevent the release from happening, it may be required that side actions be incorporated into the design.

Side actions pull coring in a direction other than the direction of the mold separation. This adds flexibility to the part design and at times, may increase the cost of the mold.

Working with an experienced plastic injection molder and engineering team is a critical component to avoiding many issues that can occur during the design and development process. If you keep these factors in mind during the design process, and align with a knowledgeable plastics engineer, you will be on track to get your product to market quicker and within your budget.

To ensure a plastic quality part, there are three major areas of focus throughout the design stage:

Proper plastic part design

Proper material selection plastic part design

Processing conditions for plastic injection molding

our designers and engineers have over 50 combined years of experience in designing parts for plastic injection molding, selecting materials, and processing resins (specializing in engineering and high performance resins). which was designed to demonstrate the basic elements of proper plastic part design.

Designing Parts for Up & Down Molding Helps Control Cost

Designing a part that can be molded with a “straight pull” or “up & down” motion is a great way to keep the cost of the mold down. A straight pull mold is designed so that when the two halves (A side and B side) of the mold separate from each other, there is no plastic blocking the path of the metal in the direction of the pull. Undercuts on the part cause this blockage of path and require an action in the mold (cams, core pulls, etc.). Action in the mold can have a major impact on the cost (and overall size) of a mold.

1) Uniform Wall Thickness Helps to Prevent Defects

2) Draft Allows for Parts to Release from the Mold

3) Holes Enhance Part Functionality and Reduce Weight

4) Bosses Aid in Assembly and Mounting

5) Ribs Enhance Part Strength and Stability

6) Adding a Radius Reduces Stress on Corners

Designing a plastic part for manufacturability involves many important factors that touch on all areas of part design, tooling, material selection and production. First, it is essential to build parts around functional needs by keeping design intent or the end use in mind. Consider weight reductions, the elimination of fabrication and assembly steps, improving structural components, reducing costs and getting products to market quicker. Here are 8 important factors to consider to meet your plastic part design goals for a successful production process.

1. Material Considerations

Manufacturers often select a familiar grade of plastic from a similar application or rely on recommendations from suppliers. Resins chosen this way may be adequate, but are rarely optimal. Plastic selection is a complex task that involves many considerations, such as:

Temperature: Thermal stress that may occur during normal and extreme use conditions, as well as during assembly, finishing and shipping.

Chemical resistance: The effects that occur when any solid, liquid or gas come in contact with the part.

Agency approvals: Governmental and private standards for properties such as heat resistance, flammability, and electrical and mechanical capabilities.

Assembly: The plastic’s cooperation with all assembly steps like bonding, mechanical fasteners and welding.

Finish: The material’s ability to produce the desired finish such as gloss, smoothness and other appearance values as it comes from the mold.

Cost: Resin pricing as well as the cost calculations for manufacturing, maintenance, assembly and disassembly to reduce labor, tooling, finishing and other costs.

Availability: The resin’s availability in regard to amount needed for production.

2. Radius

Radius should always be a consideration in regard to the part’s thickness – eliminating the likelihood of areas of high stress and possible breakage of the part. A general rule of thumb is that the thickness at a corner should be in the range of 0.9 times the nominal thickness to 1.2 the nominal thickness of the part.

3. Wall Thickness

Designing your part so that wall thickness is consistent can help avoid many part defects that can occur during the manufacturing process. When plastic melts, it flows to the areas of leas resistance. If your part has inconsistent thicknesses throughout, the melt may flow into the thick areas first (depending on gate locations). When this occurs, the thin areas may not fill properly. Additionally, thicker areas tend to cool more slowly and are at risk for voids or sinking defects. Designing your part with rounded corners will also aid in the proper filling of the part during the molding process.

4. Gate Location

Gates are critical to ensuring the resin flows properly into the mold. These small components of your design are what directs the flow of resin from the runners to then be distributed through the part. Type of gate and placement has an important impact on the part’s overall quality and viability.

5. Draft

Draft is the amount of taper on the vertical walls of the plastic part. Without draft, a part may not eject from the mold, or may sustain damage during ejection. Typically, draft angles between 1° and 2° are required, but can vary depending on part restrictions and specifications.

6. Inclusion of Ribs

A plastic part that has been designed with a minimal wall thickness will not be as strong as a thicker part – which is why the inclusion of ribs may be needed to help reinforce the part’s strength. Depending on the material used, rib thickness should be between 50 – 70 percent of the relative part thickness to avoid sink marks. To avoid sinking, designers may core out material to reduce defect risk.

7. Mold Shrinkage

The shrinkage that occurs during the plastic part molding process can be as much as 20 percent by volume. Crystalline and semi-crystalline materials are most prone to thermal shrinkage. Amorphous materials are known to shrink less. Here are a few easy ways to avoid molding shrinkage issues:

Adjust the formulation

Adjust the mold design to get the dimension you want based on the expected shrinkage that will occur

Optimize the processing parameter such as molding temperature, melt temperature, and injection speed/pressure/time, cooling time.

8. Special Features

Plastic parts should be designed so that mold tools open and eject the part easily. When a part is released, the two sides of an injection mold separate in the opposite direction. When special features like holes, undercuts or shoulders prevent the release from happening, it may be required that side actions be incorporated into the design.

Side actions pull coring in a direction other than the direction of the mold separation. This adds flexibility to the part design and at times, may increase the cost of the mold.

Most of the plastic product manufacturing organizations face multiple problems during manufacturing. Some common challenges faced by plastic manufacturing organizations are:

When a part is to be ejected against the draft direction – in such cases, the designer must be aware of manufacturing constraints and the quantum of force ejection that can be done.

When there are multiple no. of lifter or slider arrangements – in such cases, tool designer must analyse the slider movement with respect to time taking into consideration the cooling time. So, in those cases, CATIA Mould Tooling workbench can really be helpful.

When designer reverse engineers a product – in such cases, achieving the desired parameter in terms of performance is a challenging task. This can be mitigated by simulating the results through virtual analysis.

Assembly of rubber part and plastic part – for a leak proof product, the designer should not prefer the parting line as it creates material flushes in those particular junctions and it results in leakage as well as breakage or tear of rubber parts from inner surface. All these challenges can be addressed beforehand by analysing the parting line position and by doing a mock up.

Plastic part design consideration plays a significant role in designing and manufacturing a plastic component. Whenever a Product Designer designs a plastic part, it is important to take care of factors such as the moulding process, selection of material, mass manufacturing process and overall area of the part around the functional need by keeping the design intent intact or the end use in consideration.

Plastic parts manufacturing is a nuanced methodology that merges artistry with intricate mechanical engineering. This multifaceted industry extends from the manufacturing plants all the way to your local stores, providing countless objects we use daily. It refers to the production process involved in transforming plastic materials into a wide range of plastic parts, including different types of plastics.

The transformation happens in various ways, each tailored to produce high-quality goods with distinct characteristics and applications. Processes like injection molding, extrusion manufacturing process, fabrication, and CNC machining are some of the core techniques in plastic parts manufacturing. The production process involved in manufacturing complex parts made of thermosetting plastics is a careful blend of technology, material science, and craftsmanship.

A critical factor in the manufacturing process is the type of plastic material used. Thermoplastics such as polyethylene, polypropylene, and polystyrene are commonly used in the industry. Nylon is another thermoplastic that is widely used due to its high strength, durability, and resistance to abrasion. Additionally, polymers called thermosets are another type of plastic material that are used in manufacturing due to their ability to withstand high temperatures and resist deformation. Each plastic processing method also directly relates to the produced part’s complexity, mechanical properties, and cost-effective large quantities manufacturing.

What is Plastic Product Design?

It is the art of creating functional and aesthetically pleasing products made primarily or entirely from plastic materials. It involves designing products that not only serve their intended purpose but are also ergonomically sound, sustainable, and manufacturable.

Materials Matter

Choosing the right plastic material is fundamental to successful product design. Plastics vary in properties, from rigid to flexible, transparent to opaque, and durable to biodegradable. Understanding these materials’ characteristics is essential to match them with your design requirements.

Design for Manufacturability

Designing for manufacturability is a core principle. The design should take into account the capabilities and limitations of the manufacturing processes, such as injection molding, extrusion, or thermoforming.

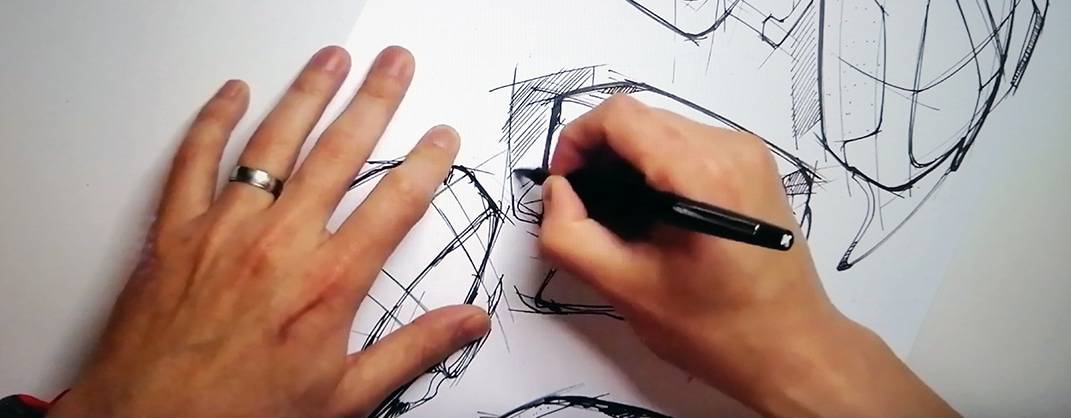

Actually, we can simplify the plastic product design process into some steps:

1: Defining requirements

2: Create a preliminary concept sketch

3: Initial materials selection

4: Design part in accordance with material properties

5: structural analysis

6: Final materials selection

7: Modify the design for manufacturing (DFM)

8: Prototyping

9: Tooling

10: Production

Plastic part design geometry is one of the most important components in the design process. It affects not only the aesthetics but also the part’s performance, strength, and durability. So if you’re designing a plastic part, here are five key geometry tips that will help ensure its success:

Always define the part features’ design intent.

Ensure that your design intent is clearly documented, so everyone involved in the project understands it.

Define the part’s design requirements those things which must be true about the part of the product to make it work correctly.

Define any constraints on how a feature can be designed, e.g., limitations on manufacturing processes or materials used in production. Some constraints may be imposed by external forces outside your control. For example, regulations imposed by safety officials or material availability.

Ensure that you understand all of these requirements and constraints before proceeding with designing any features for a plastic part.

Build a draft angle into the part.

Draft angles are used to increase the strength of parts, reduce stress, and make it easier to remove a part from its mold.

A draft angle is the angle of a wall on a part as it transitions into another surface. The draft angle is also known as an undercut or negative draft angle.

Add ribs and gussets for added strength and durability.

Ribs and gussets are used to increase the strength and durability of a plastic part design. They can also be added to increase stiffness. This is important in parts needing to be stiff enough to withstand loads coming from their intended use. The placement of ribs and gussets must be carefully considered because they affect other aspects of the part’s design:

The thickness of ribs will determine the amount of material used in areas where ribs are not needed or have been removed.

If you plan on printing your part on a 3D printer, then ribs should not be placed over areas where internal supports will be printed, as this could cause problems with printing accuracy if it causes issues with support removal later on down the line

The wall thickness should be uniform throughout the entire part.

One of the most important rules when designing a plastic part is ensuring its wall thickness is uniform throughout. This can be very difficult if you’re trying to model something with complex proportions, like an intricate shape or an irregular surface. However, all parts must have the same wall thickness, so they don’t crack during production or in use.

The recommended minimum wall thickness for any given material is determined by three factors: 1) The desired strength of the part; 2) The amount of plastic needed for production; 3) The length/width ratio of your design (i.e., whether it has a lot more surface area than depth/thickness).

Place threads in cavity walls to reduce stress concentrations.

It’s important to place threads in cavity walls to reduce stress concentrations. Stress concentrations are points where the stress is high, and if you have a part with many of these points, it can be difficult for the part to handle the stresses without breaking. Threads are one way to get around this issue.

Threads can be used at the top and bottom of the cavity wall where no other loads are applied directly on them (usually at least two millimeters away from any other load-bearing surfaces). The distance from a threaded hole or pinhole should be equal in all directions: i.e., if you put it 1 mm from one edge and 2 mm from another edge, you should put it 3 mm from an adjacent surface so that they are equidistant from each other.

Injection-molded plastic part design is a lot like parenting.

The job falls into your lap, you have zero qualifications, and yet, you are supposed to do it perfectly while blindfolded. It’s difficult to lunge forward with confidence when you are building on a poor foundation.

The result is that you proceed with the project with a “learn-as-you-go” approach. Even so, there’s still opportunity to avoid common mistakes, make smart decisions, and release a smart, young, well-prepared injection-molded part into the universe, ready to make a big impact and change the world.

There are engineering schools that offer an exclusive plastics track, but they aren’t numerous. Furthermore, a “track,” is an optional route at the tail end of your curriculum as opposed to a core/required course. Most engineering schools address plastics in material science classes, but this aims to understand materials at a microscopic level — learning their bonding structure, and the behavior you can expect from a part made of plastic.

There are two important components of plastic part design that are absent in most engineering curricula: mold design and plastic part design. Mold design includes the part cavity, run time, gate diameter, cooling channels, cycle time, and the general mechanics of manufacturing a plastic part.

The other missing component is plastic part design — understanding the form that part must assume for proper manufacturing.

To clarify: I’m not criticizing the schools, just identifying a void. There’s simply so much engineering theory to cover in four years, and students are simply hoping to get through engineering school with some breath still left in them.

Moving on to industry, upper management is blind to this void. They aren’t approaching each designer and questioning our knowledge of our craft. They are making the assumption that, “Yes, you are an engineer, and obviously this task, plastic part design, lands in your territory. You know how to do this.”

There are four key sources for learning plastic part design, listed here in order of increasing impact:

Networking with other engineers

Touring an injection molding facility (local and overseas)

Talking to a toolmaker

Looking at “bad” parts (design flaws)

I’ve learned the most from bad parts. I’ll share– some design tips with you that are fundamentals, and I’ll also share some tips on how to enhance the product beyond simply function and form.

Furthermore, you’ll find that the best/smartest designs are all around (your desk and chair even), so look for inspiration. My favorite plastic design right now is the Cuisinart ice cream maker. It’s a reminder that the things we engineer should be smart, simplified, and easy to use/operate.

Perhaps you aren’t designing a consumer product.

The real message is that the smartest designs are actually very simple and have creative features to get the job done. Don’t look only to other plastic designs. You can apply all of your knowledge about things you already know, such as sheet metal. A lot of the principles can be applied in plastics.

Whenever you begin a design project involving plastic parts, where your end goal is to have the component injection molded, you’ll want to consider some things on the front end of your design process that will allow for time and money to be saved during the production phase of your project. This foresight at the beginning stages of product design will be useful in understanding the limitations and challenges faced by the manufacturers of your product.

These 10 considerations are by no means exhaustive when considering the best plastic injected part design, but they will for sure get you very close to where you need to be and at the very least, point you in the right direction. So let’s check out these helpful tips:

1. Consider the Parting Line

Try and imagine your part being molded. It can be difficult for some to think in the “negative”, and by that I mean visualizing the empty cavity space that the liquid plastic will fill in order to mold into a plastic part. Inevitably, once that cavity space is filled, your part will have to be ejected from that space. In order for that to happen, the two mold halves will have to separate, leaving behind your plastic injected part in one side of the mold (preferably the side where you plan on ejecting from). You need to visualize and plan for where this “parting line” will be so as to ensure that your part does not get trapped in the mold.

2. Avoid Undercuts (If Possible)

Undercuts on your part wont necessarily make it more difficult to mold your part, but rather more difficult to demold. The undercut portion of the plastic part will get trapped inside your mold once the part is cooled and hardened, and in turn making it impossible to eject from the mold without other mold actions. Many times, undercuts are a necessity for part function. Side actions and lifting mechanisms will have to be introduced to your tool in order to deal with the ejection of your part. Sometimes this is not avoidable, but if you are looking to save on tooling cost, it might be worth trying to redesign in order to eliminate necessary tooling costs.

3. Uniform Wall Thickness

You want to make sure that you try and make the wall thickness of your part as consistent as possible. It’s alright if you don’t have uniform wall thickness to some extent, but uneven wall thickness greatly increases the likelihood of sink marks, warpage, voids, molded-in stress, longer cooling times, and even material flow restrictions. If wall thickness must be uneven, it is best to have smooth transitions that taper over some distance. The size of the part and the ability of the material to fill will determine the minimum wall thickness allowed for your plastic injected part.

4. Shrinkage and Warpage Considerations

All materials shrink at different rates and at varying degrees within the cooling process of your injection molding operation. Shrinkage and warpage are two different phenomena that can occur. Shrinkage occurs where there is a difference between corresponding linear dimension of the mold and the molded part. Warpage is a dimensional distortion in a molded plastic caused by excessive residual stress in the part. There are various things to consider when trying to control either one of these occurrences. Material considerations, part geometry considerations, tooling considerations, and processing considerations all play a part.

5. Watch The Sharp Corners

Sharp corner are to be avoided at all costs. Sharp edges, such as corners of a square hole, will produce a part with high levels of molded-in stresses. These much of the time result in weak points that lead to part failure and cracking. Adding radii to sharp corners will reduce the amount of molded-in stress. Radii redistributes the stress more evenly and facilitates the flow of the material and ejection from the mold. Stresses rapidly build whenever the inside corner id less than 25% of the nominal wall thickness of the part.

6. Structural Support

As a product designer you want to minimize the amount of material required to fill your part, while at the same time increasing its structural integrity. Thin walls need some sort of support so that the walls don’t warp or collapse. Ribs are commonly employed on injection molded parts in order to stiffen relatively thin parts. Ribs, bosses and other projections on the piece part wall will greatly strengthen your part while, but if done incorrectly can contribute to other molding issues such as sink marks and non-fills.

7. Add Draft

Draft is the angling of otherwise vertical walls in order to prevent constant contact with the molding cavity during the mold opening. All vertical walls oriented normal to the direction of mold pull will need to have draft ideally at 1 degree minimum. There are special consideration for ribs and bosses, and textured surfaces will need to add 1 degree per side for each .001″ depth of te

Design for manufacturability (DFM) is the general practice of designing parts so that they are also efficient to produce. While specific best practices vary by manufacturing technology, the ultimate goal of DFM in general is to optimize part design so as to minimize the manufacturing costs — without sacrificing on performance or function. DFM also helps you identify potential issues or defects early and avoid disruptive re-designs down the line, which is why assessing possible manufacturing methods is crucial during the initial design and prototyping phases.

Intentional, method-focused design is especially important when attempting to produce parts with complex geometries or intricate features. And while there are many viable manufacturing methods for producing parts with complex geometries, injection molding is among the most common.

DFM is especially important for injection-molded parts, as the hard tooling and molds used to create injection-molded parts introduce a number of variables that may impact design — including mold temperature, material temperature, and air pressure. What’s more, injection molds are expensive and time-consuming to tool, and the process typically only becomes cost effective when producing parts in high volumes, so consistency and repeatability are critical when designing parts with complex geometries or intricate features.

Here are 5 key tips for how to design plastic injection molded parts with complex features.

1. Take advantage of sliding shutoffs for clips and snap fits

Clips and snap fits are two forms of fastening mechanisms that can be incorporated directly into the injection mold design — a few common examples being tool set lids and electronics housings. Both operate similarly: on one side of the mechanism, a flexible tab of material catches on a slot or pocket in the mating part, thereby securing the two.

Sliding or telescoping shutoffs are components machined into one side of the mold that extend into the other half, sliding into place when the mold is closed. This prevents material from flowing into particular areas, which makes it possible to easily incorporate features like hooks and holes (including long through-holes) without the need for expensive side actions, bumpoffs, inserts, and other features that increase the cost and complexity of the mold design.

Sliding shutoffs can be designed to have the same tab and slot to match the part’s clips and snap fits, creating features that fit together securely and retain enough flexibility to pull apart without breaking. Shutoffs can reduce mold design and operating costs and also generally be used as a workaround for undercuts and recessed features.

In general, both the part and mold should have a minimum of 3 degrees of draft to prevent metal from rubbing against metal, which can create flash and damage the shutoff.

2. Choose the right material for living hinges

Living hinges, another flexible lid feature, are an excellent way to attach the two halves of injection molded plastic components (think of the lids on the individual containers of a weekly vitamin dispenser, for instance).

While material consideration is always a critical consideration in design and product development, it should be your primary concern when designing living hinges. Polypropylene, for instance, is better-suited for this feature than polycarbonate (which can be an excellent material for clips and snap fits). Depending on the range of motion that’s expected of the lid, you may need to incorporate a radius at the hinge’s midpoint to allow the two parts to close more easily.

3. Keep an eye on wall thickness

Wall thickness should remain uniform whenever possible, as variations in thickness can introduce serious complications. Parts with non-consistent wall thickness are at risk of warping (caused by different sections of the part cooling at different rates, which creates internal stress that bends the part permanently).

Variations in wall thickness, like this example, can lead to sink marks, voids, and warping.

Furthermore, if the walls of a part are overly thick or thin, further issues may arise. For example, thin walls and poorly designed support ribs can impede flowability, causing short shorts (or incomplete mold fills). On the other hand, parts with thick walls and poorly designed ribs are prone to developing sink marks, or impressions on the surface of the part caused by the interior resin cooling faster than the exterior material. If you see signs of either flaw, it might be time to reexamine your mold design.

4. Add draft and reduce the height of tall features

Tall features like bosses, ribs, and standoffs may require you to incorporate greater draft angles (generally up to 3°) to ensure the part leaves the mold without drag lines or other ejection issues. Bosses and tall features allow for threaded inserts and additional part strength, but they increase the risk of developing sink marks.

Furthermore, increasing the height of ribs and other features likewise increases the depth of the mold, increasing the need for longer end mills, more venting, and slower cutting rates during the machining process. One way to work around this is to support bosses with peripheral vertical ribs, which have thinner walls, reducing the chance of sinks.

FR Injection Molding drafts2Long Description

Angled bosses and other features increase the complexity of production, as the axis of the boss no longer aligns with the parting line or the line of pull — which all but necessitates that an insert will need to be manually loaded into the mold before each shot.

5. Be strategic about text and logos

Text (such a product or company name) or logos are commonly added to injection molded products. The good news is that small font sizes are actually fairly easy to achieve through injection molding — so long as you follow a few key guidelines.

First, text should be a sans-serif font and the shortest stroke length (the crossbar of a T or a A, for example) must be at least 0.020” in length. Raised text is easier to read and to produce than text sunk into a part’s surface. Unless the text is inordinately large, it should not be more than 0.015” tall.

Injection molded plastic parts have some wonderful benefits including scalability, the ability to make simple to extremely complex parts, and uniformity, the ability to make hundreds to millions of virtually identical parts. However, the building and maintaining of injection mold tools can be expensive and making tool changes can be challenging.

Whatever the project, industrial designers, engineers and product designers may face some challenges when designing for injection molding. The following details three mistakes designers should avoid for successful injection molded parts.

Non-Uniform Walls

On average, the minimum wall thickness of an injection molded part ranges from 2mm to 4mm (.080 inch to .160 inch). Parts with uniform walls thickness allow the mold cavity to fill more precisely since the molten plastic does not have to be forced through varying restrictions as it fills.

If the walls are not uniform, the thinner sections cool first. As the thicker sections cool and shrink, stresses occur between the boundaries of the thin and thick walls. The thin section doesn’t yield to the stress because the thin section has already hardened. As the thick sections yields, warping and twisting of the part occurs, which can cause cracks.

If design limitations make it impossible to have uniform wall thicknesses, the change in thickness should be as gradual as possible. Coring is a helpful method where plastic is removed from the thick area, which helps to keep wall sections uniform. Gussets support structures can also be designed into the part to reduce the possibility of warping.

Not Utilizing Draft

Mold drafts facilitate part removal from the mold. The draft must be in an offset angle that is parallel to the mold opening and closing. The ideal draft angle for a given part depends on the depth of the part in the mold and its required end-use function.

Allowing for as much draft as possible will permit parts to release from the mold easily. Typically, one to two degrees of drafts with an additional 1.5 degrees per 0.25mm depth of texture is sufficient.The mold part line will need to be located in a way that splits the draft in order to minimize it.

Sharp Corners

Sharp corners greatly increase stress concentration, which, when high enough, can lead to part failure. Sharp corners often come about in non-obvious places, such as a boss attached to a surface, or a strengthening rib.

The radii of sharp corners needs to be watched closely because stress concentration varies with radius for a given thickness. The stress concentration factor is high for R/T values, less than 0.5, but for R/T values over 0.5 the concentration lowers. It is recommended that an inside radius be a minimum of 1 times the thickness.

In addition to reducing stresses, the fillet radius provides a streamlined flow path for the molten plastic, resulting in an easier fill of the mold. At corners, the suggested inside radius is 0.5 times the material thickness and the outside radius is 1.5 times the material thickness. A bigger radius should be used if part design allows.

Plastic parts can be designed in many different varieties. But these all share the same basic principles that make a big difference with your final product. Understanding some of these can save your project a lot of time and effort.

Use an experienced Plastic Injection Moulding provider

It might seem like an obvious point, but an experienced plastic injection molding operator will help you avoid many classic mistakes made with part designs. A simple example is the placements of the gates – this is where the molten plastic will be injected into the mold. How the plastic flows and cools determines many of the properties of the part, such as seams and weak spots. Experience can dictate the best designs for your mold that will also compliment the process you wish to use.

Plastic objects need to cool before they come out of the mold, which will result in slight shrinkage. Ideally, the product should slide out easily. But if the sides are completely straight, this is far less likely to happen and you may have to force the part out, risking damage to the part as it scrapes due to friction. Adding a very slight taper to the external sides of the part fixes this problem. It’s a very simple idea, yet hugely effective and a fundamental principle of injection molding design.

Sink marks, which is where flat surfaces instead curve inwards – as if the plastic wall as sunken in – is a common problem with plastic molding. This happens because the different areas in the part didn’t cool uniformly. It’s mainly a question of space and time: areas that need more plastic will take longer to fill and cool, raising the risk that they will deform as the rest of the part cools faster. The way to avoid this is to try and keep the main walls’ thicknesses as uniform as possible.

Avoid hard corners

As molten plastic moves into the mold, it will attempt to fill every nook and cranny. But hard and sharp corners are much more difficult to fill. This can cause turbulence in that area, leading to poor fills and other shape problems. Professional designers thus prefer to use slightly rounded corners: these help the plastic flow more comfortably into the corner, filling it uniformly.

Know your materials

Know what type of plastic you want to use or what your options are. Different plastics have different properties, such as their viscosity (how well they flow when heated) and their cooling rate. This can be further altered by additives. The material you use will have a lot to do with the purpose of the part – for example, you may want UV resistance. Bt this can impact other properties and how the plastic responds to different designs. It is quite possible to have a mold made that will not work with the intended material, so do your homework to ensure you get a happy harmony.

The product design process is a vital stage in the production of any product. We work with independent Product Design agencies that don’t just work within the Plastics industry, but they are able to design for manufacture in any material that is right for your project. Therefore, if your project requires multiple materials, metals, electronics etc, this can all be catered for.

We use this independent route instead of having our own in-house designers as we feel this gives our clients the best possible options for their products and components, rather that purely designing for plastic injection moulding.

Hi Looney, good idea! maybe we can work together :-)

There are hundreds of plastic materials available, all with different performance characteristics. You need to understand what plastic will work best for your application. You should also understand the stresses that will affect the performance and the life of the part. Key questions to answer are: will part stress occur repeatedly or will it be a one-time occurrence? Will the stress in a moving plastic part experience a continual peak load and relaxation or will it be under constant load. What chemicals will come into contact with the part? Some plastics are very sensitive to specific chemicals whereas others are not. Both the plastic material supplier and an experienced molder will prove helpful in selecting the correct material for the application.

Molded plastic parts may be designed with a variety of surface finishes, from a high gloss to a rough texture. The choice of surface finish is usually based on cosmetic considerations. A glossy finish can enhance the appearance of a part while a textured surface may help to mask sink marks or parting lines.

Surface finish should be specified so it does not interfere with ejection of the part from the mold. The smoother the finish, the more easily the part is ejected from the mold. An extremely rough surface may hinder ejection from the mold. Rough finishes tend to function much like an outside dimension undercut thus preventing the part from slipping easily out of the mold.

When not otherwise specified, the surface finish standards of the Society of Plastic Engineers and the Society of Plastic Industries should be followed.

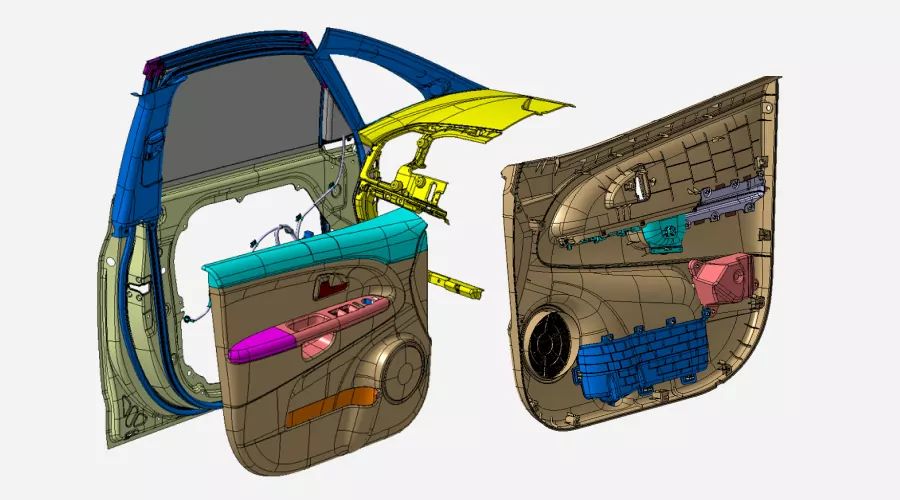

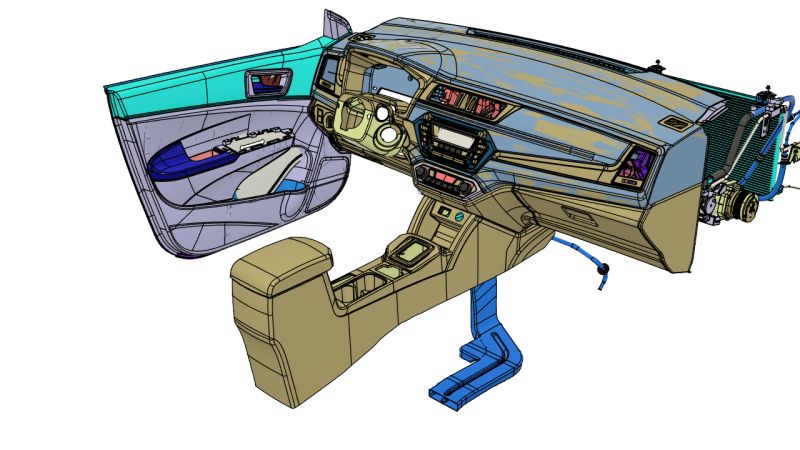

In the last couple of decades, use of lightweight alternatives such as plastics and composites has dramatically increased, with its applications well entrenched in automotive, aerospace, consumer electronics industry.

Today’s car for example, has more than 150 kilograms of plastics on board in the form of seats, dashboards, bumpers, and engine components. Boeing 787 on the other hand has 50% carbon fibre-reinforced plastic and other composites in its airframe. The company says it has used more carbon composites and plastics than ever before in the 787 model.

Plastics offer good mechanical properties and are relatively lighter than metal, making products more efficient, while providing enough toughness to withstand the test of time. However, it is important that designers be sensitive to certain physical and mechanical properties of plastics as it is not as strong as metal, has relatively lower density than metal and is poor conductor of heat and electricity

Injection molding is the most commonly used manufacturing process but due to its intricacies product designers need to make adequate design considerations to ensure that part designs focus on maximizing molding performance and reducing tooling costs , an area that often plague the injection molding industry.

Plastics tend to have higher rates of thermal expansion than metals and thicker sections shrink more than a thinner section, resulting in warpage or sink mark during the molding process. Stress concentration is another area that is of particular concern for plastic part manufacturing. These stresses can be the result of a continuous load, warpage, or any other issue related to design, material, processing, or tooling factors. Additionally there can be many latent defects in plastic parts that can not be detected with routine quality control.

Plastic part performance and cost can be significantly enhanced by proper part design features. Through the use of simple designs and by following general moldability guidelines for plastic parts, design engineers can avoid problems occurring during manufacturing and also reduce the cost of parts. These factors require designers to introduce adequate design features that can lessen the stress level within a part and help develop low-shrinkage, warp-free parts.

Creating a high-quality, reliable precision injection molded plastic part involves careful planning, prototyping, and testing. Although most part issues originate during the first steps of manufacture, they can be easily avoided from the outset by working with a trusted turnkey molding manufacturer, rather than a company that outsources their work.

These types of molding companies work with outside designers and then contract another company — often an offshore operation — to build the mold, essentially relinquishing control over operations in the process. Turnkey manufacturers, on the other hand, handle all steps under one roof, allowing for full oversight and ensuring accountability and quality.

Plastic injection molding allows for the production of precision parts at low costs, but high-volume molding processes require specialized part design. With the right design, consistently high-quality parts can be produced in bulk, avoiding expensive processing errors and delays.

Before beginning the injection molding design process, the following factors should be taken into account:

Wall Thickness Rib Design Boss Design Corner Transitions Weld Lines Gate Placement Vent Placement More Information

In the last couple of decades, use of lightweight alternatives such as plastics and composites has dramatically increased, with its applications well entrenched in automotive, aerospace, consumer electronics industry.

Today’s car for example, has more than 150 kilograms of plastics on board in the form of seats, dashboards, bumpers, and engine components. Boeing 787 on the other hand has 50% carbon fibre-reinforced plastic and other composites in its airframe. The company says it has used more carbon composites and plastics than ever before in the 787 model.

Plastics offer good mechanical properties and are relatively lighter than metal, making products more efficient, while providing enough toughness to withstand the test of time. However, it is important that designers be sensitive to certain physical and mechanical properties of plastics as it is not as strong as metal, has relatively lower density than metal and is poor conductor of heat and electricity

Injection molding is the most commonly used manufacturing process but due to its intricacies product designers need to make adequate design considerations to ensure that part designs focus on maximizing molding performance and reducing tooling costs , an area that often plague the injection molding industry.

Plastics tend to have higher rates of thermal expansion than metals and thicker sections shrink more than a thinner section, resulting in warpage or sink mark during the molding process. Stress concentration is another area that is of particular concern for plastic part manufacturing. These stresses can be the result of a continuous load, warpage, or any other issue related to design, material, processing, or tooling factors. Additionally there can be many latent defects in plastic parts that can not be detected with routine quality control.

Plastic part performance and cost can be significantly enhanced by proper part design features. Through the use of simple designs and by following general moldability guidelines for plastic parts, design engineers can avoid problems occurring during manufacturing and also reduce the cost of parts. These factors require designers to introduce adequate design features that can lessen the stress level within a part and help develop low-shrinkage, warp-free parts.

Designing products with molded plastic components and assemblies is becoming a more attractive option. New high performance plastics and innovative molding processes make this possible. Injection molded plastic parts offer an important combination of flexibility, toughness, and chemical resistance for cost effective, long-term performance in a range of applications. However, not every plastic part design can be efficiently injection molded. So working with an experienced molder with many years’ experience with high performance plastics and complex projects is important to a successful outcome. That way, you can be assured that your molded components and assemblies are both functional and within budget.

When designing a new plastic part, Wall thickness strongly influences many key part characteristics including mechanical performance, appearance, moldability and durability. So, to work with wall thickness, instead of increasing the entire wall thickness, the designer can check whether any kind of ribs, corrugations or curves can be added to get the same strength in the part as with increased wall thickness, as it leads to more weight and less moldability. By providing radius for each element instead of sharp edges, part ejection becomes easier during moulding process. Sharp edges create wear and tear which may result in malfunctioning of the final component after repeated use. The designer can then do a stiffness analysis from Analysis section before finalizing the product design.

Designing a part for manufacturing is a crucial component of getting a product to market, and designing that part for plastic injection molding requires some special considerations. Here are five tips for designing the perfect part.

Prototypes

Creating a prototype is an essential part of the part design process, particularly for injection molding. An early prototype can save on costs by helping to identify potential problem areas for the flow of plastic through the mold, cooling without warping or sinking, and possible ejection issues. Prototypes also allow you to physically examine and test a part before taking the next step to full-scale production.

Mold and Part Interaction

The simplest and most cost-effective design will allow parts to be molded with a simple open-and-close action of the mold rather than more complex (and more expensive) side action or lifting mold mechanisms.

Plastic Flow

Thick to Thin – A critical part of planning any part for plastic injection molding is to take into consideration the way plastic will flow through the mold. You want to make sure it will flow through rapidly, smoothly, and evenly. The best designs will force plastic to start in the thickest areas and progress to thinner areas which helps prevent blockages if plastic cools too quickly in thin areas preventing material from reaching the areas beyond that point.

Wall Thickness – Consistent wall thickness for best flow will aid in the smoothest flow of plastic and will help prevent warping and unattractive sinks during the cooling process.

Curves – Rounded corners and smooth transitions rather than sharp angles and corners will keep the plastic flowing easily through the mold, helping to reduce stress on the plastic and prevent warping and weakness.

Mold Ejection

Getting your part out of the mold after it’s cooled is just as important as getting the plastic properly into the mold in the first place. Adding an appropriate taper (draft angle) to parts will make them less likely to stick in the mold, and will add to the stability of parts. Rough surfaces for parts can also make them difficult to eject from molds.

Materials

The types of plastics used for parts should be carefully chosen. Each kind of polymer, additive, and filler has different suitabilities for different types of parts. For the best results, take into consideration the stress and strains on the part, the strength it will need, its durability and lifespan, the cost of different material choices, and, of course, its physical appearance. There’s a lot to take into account when designing a part for plastic injection molding.

Designing an injection molded plastic part requires optimizing the part with respect to various stakeholders’ needs throughout its life cycle. The conditions in which a product is operating in service are often inadequately understood or specified, resulting in wrong material selection, which in turn leads to failure when the product is used. Many aspects interrelate with the initial part design and the essential rules of each should be taken into account to ensure a well-functioning plastic product. Regardless, a part design often passes sequentially from concept development to the manufacturing phase with features that unnecessarily complicate production, add costs and weaken the intended embodiment of the product. Therefore, a checklist was developed to ensure that oversights do not happen and verify that a design fulfills the requirements set for it.

First considerations for Plastic product design:

Now, if this is your first approach to plastic product design, you’re probably thinking about what the primary factors are to look for this service resource. To make the most appropriate decision making to your business needs, here are some useful considerations to think about and share with your designer:

Why is this design necessary?

Which need are we trying to meet?

How will its function help our product?

Are we going to replace other existing products?

Are there already similar products on the market?

Are there any patents or protected designs that could conflict with this new design?

How will its use and usability criteria make our product attractive to the final consumer?

Who is its potential user?

Are there any possibilities of misuse of my product that could harm the user?

Will it be a single-use product? How many uses will it have?

Is it a seasonal product?

Is it a promotional product?

How important is the appearance of the product?

Designing a plastic part for manufacturability involves many important factors that touch on all areas of part design, tooling, material selection and production. First, it is essential to build parts around functional needs by keeping design intent or the end use in mind. Consider weight reductions, the elimination of fabrication and assembly steps, improving structural components, reducing costs and getting products to market quicker.

Plastic part design consideration plays a significant role in designing and manufacturing a plastic component. Whenever a Product Designer designs a plastic part, it is important to take care of factors such as the moulding process, selection of material, mass manufacturing process and overall area of the part around the functional need by keeping the design intent intact or the end use in consideration.

While engineering plastics are used in many diverse and demanding applications, the most common design elements or features influencing the overall area includes wall thickness and radius, ribs, bosses, draft etc.

molding engineers and designers can work with you to develop and design your plastic injection molded component. To ensure a quality part, there are three major areas of focus throughout the design stage:

Proper plastic part design

Proper material selection plastic part design

Processing conditions for plastic injection molding

The mold designers and plastic engineers should have rich combined years of experience in designing parts for plastic injection molding, selecting materials, and processing resins (specializing in engineering and high performance resins).

Designing a part that can be molded with a “straight pull” or “up & down” motion is a great way to keep the cost of the mold down. A straight pull mold is designed so that when the two halves (A side and B side) of the mold separate from each other, there is no plastic blocking the path of the metal in the direction of the pull. Undercuts on the part cause this blockage of path and require an action in the mold (cams, core pulls, etc.). Action in the mold can have a major impact on the cost (and overall size) of a mold.

Proper wall thickness is one of the most fundamental requirements in designing a part for plastic injection molding. Plastic shrinks as it cools which can lead to defects such as sink marks, voids, stresses, and warping. Plastic resin solidifies in the mold nearer to the outside of the part (closest to the mold surface). Thick sections of a part tend to pull inward, creating stresses, sink marks, or voids. Since thinner sections cool quicker, stress can build in the part between thinner and thicker sections, resulting in part warpage.

In order to bring a new plastic product to market and ensure its future industrial viability, it is essential to take into account design, materials, production and processing, as well as managing and/or recovering, this product once its life cycle has ended.

In the initial phase, it is important to be aware of possible legal restrictions, limitations arising from similar developments already on the market and product certification requirements. Product features must also be considered (weather resistance, resistance to chemical agents, resistance to high or low temperatures, chemical incompatibility, lack of mechanical properties, etc.).

Once the viability of the product has been analysed, there are three keys to successful development: design, materials and the manufacturing process. The optimum product will be obtained from the best combination of the three.

Now, if this is your first approach to plastic product design, you’re probably thinking about what the primary factors are to look for this service resource. To make the most appropriate decision making to your business needs, here are some useful considerations to think about and share with your designer/supplier combo:

Why is this design necessary?

Which need are we trying to meet?

How will its function help our product?

Are we going to replace other existing products?

Are there already similar products on the market?

Are there any patents or protected designs that could conflict with this new design?

How will its use and usability criteria make our product attractive to the final consumer?

Who is its potential user?

Are there any possibilities of misuse of my product that could harm the user?

Will it be a single-use product? How many uses will it have?

Is it a seasonal product?

Is it a promotional product?

How important is the appearance of the product?

Working with an experienced plastic injection molder and engineering team is a critical component to avoiding many issues that can occur during the design and development process. If you keep these factors in mind during the design process, and align with a knowledgeable plastics engineer, you will be on track to get your product to market quicker and within your budget.

Designing a part that can be molded with a “straight pull” or “up & down” motion is a great way to keep the cost of the mold down. A straight pull mold is designed so that when the two halves (A side and B side) of the mold separate from each other, there is no plastic blocking the path of the metal in the direction of the pull. Undercuts on the part cause this blockage of path and require an action in the mold (cams, core pulls, etc.). Action in the mold can have a major impact on the cost (and overall size) of a mold.

Product design is a big concept, and your focus on plastic product design is only part of it

Now, if this is your first approach to plastic product design, you’re probably thinking about what the primary factors are to look for this service resource. To make the most appropriate decision making to your business needs, here are some useful considerations to think about and share with your designer/supplier combo:

Why is this design necessary?

Which need are we trying to meet?

How will its function help our product?

Are we going to replace other existing products?

Are there already similar products on the market?

Are there any patents or protected designs that could conflict with this new design?

How will its use and usability criteria make our product attractive to the final consumer?

Who is its potential user?

Are there any possibilities of misuse of my product that could harm the user?

Will it be a single-use product? How many uses will it have?

Is it a seasonal product?

Is it a promotional product?

How important is the appearance of the product?

Plastic design is a combination of geometry and choice of materials. These two factors interrelate with each other, and knowledge of each area is important to achieve a comprehensive design. For plastic design, there are specific rules regarding part geometry, which supports in achieving the intended embodiment.

To manufacture a new plastic product design, your supplier must have knowledge of industrial design, materials, industrialization, and product management, once its life cycle is over. Elements such as walls, ribs and holes require detailed scrutiny, for which general design guidelines and checklists provide basic principles.

if you’re new to designing molded plastics or if you’re curious about the process.

Use a uniform wall thickness. This will promote uniform patterns, uniform molded-in stress distribution and uniform shrinkage. Having a uniform mold will also make warping less likely.

Avoid abrupt transitions from thin to thick. All parts require some variations with wall thickness including features such as ribs. Because of the structural differences, the transition should be as gradual as possible in order to avoid flow hesitation.

Avoid sharp corners as much as possible. Sharp corners act as stress concentrators that can lead to crazing, cracking, increased susceptibility to chemical attack and part failure. To best avoid sharp corners with plastic product design, use generous radius at all corners. Radius corners make it really easy to add fillets or chamfers to avoid sharp corners altogether.

Use ribs to improve part stiffness in bending. Ribs are also used in plastic parts to prevent warpage. If ribs aren’t designed properly relative to the surfaces they’re attached to, problems such as sink marks, warpage and part failure can occur.

Use the least thickness compliant with the process, material or product design requirements. This will ensure rapid cooling, short cycle times and minimum shot weight. Combined, this will result in the least possible part cost.

Try to design parts to facilitate easy withdrawal from the mold by adding draft in the direction of mold openings or closings. The amount of draft angle depends on the depth of the part in the mold and its required end function.

Injection molding is not the one and only perfect plastic manufacturing method. However, it has its set of disadvantages but the benefits clearly outweighs its cons with a huge disparity. All of these information on how to design plastic products through injection molding may seem so sketchy if you are still new to plastic manufacturing. It needs time and experience before you get yourself fully acquainted to injection molding as a method on how to design plastic products. An experienced plastics manufacturing company can help you with the details.

Getting great results from plastic injection molding requires a respect for the properties of thermoforming plastic resins and how they behave inside of a mold tool. Using good design practices at the beginning of the product development cycle will help you to avoid common pitfalls and will improve the look and performance of your parts. you always are some suggestions for the most common causes of defects in plastic injected molded parts and how to avoid them for our next project. thanks you so much!

Designing uniform wall thickness is essential to controlling the distribution of heat within the part during molding.

To get the best results, follow these design tips for wall thickness. Be careful to note the type of plastic being molded, which may effect the rate of shrinkage in the mold.

Adjacent walls should be equal in thickness wherever possible, but should in no case differ more than ~50%

Long wall sections should be supported with ribs or gussets, instead of making them thicker for strength

There should be a draft angle of 1 degree for every 2 cm in wall height

Walls should have a slight radius at their base to relieve stress which can cause cracking or deformation

Material and Thickness are very important when designing a plastic product

Depending on (1) how the product works, (2) the environment it will be in and (3) the preference of the designer, a material should be selected. These materials change how the part feels, looks and operates. Some are flexible, some are rigid, some are strong, some are brittle. The type of material chosen will often have a significant effect on the design of the part. Some support ribs may need to be removed or added, walls may need to be thicker or thinner, etc.

The plastic product design process offers many versatile solutions and unique benefits, but it’s a practice that depends on the strength of its design. The injection molding part design must be developed to maximize the efficiency inherent in high-volume molding. Plastic product and mould design, tool building, plastic material selection, and Injection molding manufacturing process are the four key factors that go into making a high-quality plastic injection molded part. During both the injection and cooling stages of the manufacturing process.

There are some differences between plastic product design and other product design. Here I would like to share some experience about plastic product design:

1. Wall thickness

Thin walls are advisable in plastic manufacturing for shorter cycle times and being able to produce more plastic part designs in shorter production lead time. Thinner walls also makes the cooling process faster. Ideal wall thickness from 0.08″ (2mm) to 0.16″ (4mm), but thin wall injection molding can go as thin as 0.02″ (0.5mm).

However, wall thickness also depends on the type of plastic material being used. Here are the recommended wall thickness for various plastic materials; ABS resin is between 0.045 and 0.140 inches, Acrylic is at 0.025 –0.150, Liquid crystal polymer at 0.030 -0.120, Nylon at 0.030–0.115, Polycarbonate at 0.040 – 0.150, Polyester at 0.025 –0.125 and Polypropylene at 0.025– 0.150.

2. Ribs

Adding ribs helps increase the bending stiffness due to the increased moment of inertia. This is a suggested option instead of adding thickness to the wall. Here are recommendations with ribs in plastic production;

Rib’s thickness should not be more than 60% of the nominal thickness value.

Height should be three times lower than the wall thickness.

Draft angle is at 25 degrees.

The ribs position must be perpendicular to the axis where the bending occurs.

Corners of the attachment points must be rounded instead of having them pointed.

3. Bosses

Bosses are layers wherein fasteners are attached and threaded inserts are located. Recommended specifications for bosses are the following;

Bosses’ wall thickness should not be more than 60% of the main wall.

Base radius should be at least 25% thickness of the main wall.

Bosses should be supported by ribs connecting to walls adjacent from their position or gussets at the bottom the mold design.

Ribs should be used to isolate bosses in corners of the design.

Plastic product designer’s Services include dynamic, linear and non-linear analyses, consulting, CAD development and design and prototyping.

Plastic Part design could become tricky and compromises and trade-offs usually lead to failures. Automotive OEM’s will mainly use plastic material in cosmetic components and some other non-load carrying components.

Main features of plastic part design would include:

Good Knowledge of Material Database – There are many sources of data available for 100’s of plastic material types and grades in the market. But very few would provide complete understanding of material properties. When select the plastic materials, temperature and time variation of strength should be considered, as it could significantly lead to development of creep & fatigue.

Type of Loading & Application – Short term cyclic loading or long term constant load. In both cases, the maximum allowable stresses are going to be significantly lesser than the tensile strength of material. The environmental exposure of the part can also decide the life of the part as it degrades on coming in contact with chemicals, UV rays, sunlight and temperature.

Part Design Features – Many factors like ribs, notches, wall thickness, holes can contribute to stress concentration & residual stresses in the part. Thus careful consideration of part features should be done in order to optimize the stress lines within the part. For example, any abrupt change in wall thickness may lead to high stress concentration and thus reduce strength of the part.

Process Induced issues – process control parameters like cooling time, heating temperature, poor material mixing, poor part design leading to improper material flow can significantly affect the structural characteristics & quality of the part.

Basically, the manufacturer try to cut costs by compromising on either of these factors which should be taken care by the product engineering team of the automotive company.

When designing with plastic, our goal is to achieve a technically accurate design that works well and can effectively reduce manufacturing costs. Following these basic techniques will help achieve these goals and speed up the design process.

Today’s high-performance plastics bring many benefits to the design table, which was previously thought to be only available on metal. The first is durability. Over time, today’s high performance plastics have proven to be much stronger than metals in many applications. Every imaginable industry, from plumbing, medical and aerospace, now has hundreds of applications, and previously designed metal parts are converted into plastic.

Uniform wall thickness is the key to the design of molded parts. Uneven wall thickness can cause dimensional integrity problems such as dimensional control problems and warpage.

Material Selection – Some materials can flow through thin-walled sections and provide the proper strength for their application. However, some materials are not free to move or contain fillers to increase the strength of the selected material. These types of materials require a thicker minimum thickness.