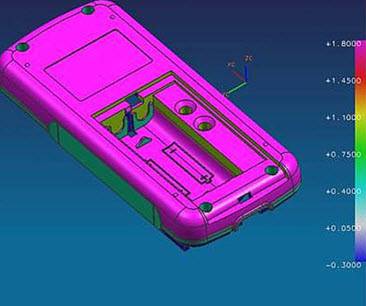

Today I check some mold designs from some Young mold designers, I find a common and Easily neglected problem—they often forget to add drafts in some areas, maybe they don’t realize it’s importance, you know, the draft facilitates part removal from the mold. If no Drafts (or taper) in a mold, we will get Unqualified products, as for how to design, I want to share some experiences:

At first, in a direction parallel to the mold opening and closing, the draft is in the offset angle, and the amount of draft angle depends on the depth of the part in the mold.

Second, how to decide the draft, I think, the best design is to make the molding part easy release from the mold, the empirical value is to allow 1 to 2 degrees of draft, with an additional 1.5° min. per 0.025 mm (0.001 inch) depth of texture.

Of course, above empirical value is a common recommendation, for many precision molding parts, their drafts have many special requirements, if you are interested in it, we can discuss more about it.

Draft angles allow for removal of the plastic from the mold. Without draft angles, the part would offer significant resistance due to friction during removal. Draft angles should be present on the inside and the outside of the part.

The deeper the part, the larger the draft angle. A simple rule of thumb is to have a 1 degree draft angle per inch. Not having enough draft angle may result in scrapes along the sides of the part and/or large ejector pin marks.

Please don’t laugh, many mold designers will ignore some in mold design.

I agree plastic product design has it’s special requirement

This is a basic principle of mold design, but some mold designers sometimes neglect it

Hello, I check your blogs regularly.I think your blog will benefit a lot of peoples in mold industry

Your blog is great! I like to read!

your remind is very necessary

Thank you for your remind, this is a plastic product’s design rule

as a product designer, I want to say this is a basic requirement when designing a plastic part

Thanks for sharing your thoughts about mold design.

Regards

that is an important detail for every mold designer

that’s very important!

Your reminding is very important for many mold designers

Great Weibo!it is very useful and interesting!

This is a very important reminding

I do remember:-)

your suggestion is correct

sometimes I really forget to do so on some area on a new product design

as a mold designer, Thank you for reminding me

sometimes that kind of job will be completed by mold designer, if you have built a good business relationship between your product company and mold company

on this issue, maybe we can discuss, actually it depends on your product.

For those primary mold engineers, this is an easily neglected problem

Pretty! Thiѕ is an extremely useful post for many mold designers. Тhanks for sharing your experience

as a mold designer, I want to say your suggestion is very important.

please don’t worry, I never forget:-)

Fresh mold designers are easy to ignore the problem

your suggestion is very good! thanks!

yes! sometimes, I really forget it:-)

sometimes on some areas of a plastic part, it does not allow to add draft

thanks for sharing your experience

this is a topic we need to discuss carefully, Maybe we can learn more

thanks for sharing your experience

Sometimes due to the special requirement of products, some places are not allowed to add draft, though it would increase the cost of the mould

but some areas on some plastic part, draft angle are banned because of function

Hi for a plastic part design, this is a common rule,actually because of special function ,there is no draft on some places of Some products

As a product designer, it’s just a basic requirement

My spouse and I stumbled over here coming from a different page and thought I should check things out.

I like what I see, so I am just following you. Look forward to looking at your web page

yet again.

Fantastic. excellent website, professional company, I think many companies which need that kind of service will contact you:-) good luck!

Very nice article. I definitely love this site.

Keep writing!

I’m really impressed with your writing skills as well as with the

layout on your weblog. Is this a paid theme or did you customize it yourself?

Anyway keep up the nice quality writing, it’s rare to see a

great blog like this one these days.

Hi it is First-rate Mold Solution Co., Ltd. Team to manage firstratemold.com

We stumbled over here by a different web page and thought

I should check things out. I like what I see so now i

am following you. Look forward to looking into your web page yet again.

You should be a part of a contest for one of the finest sites on the internet.

I’m going to highly recommend this web site!

Hi there, I enjoy reading through your post. I like to write a little

comment to support you.

Wow, incredible weblog structure! How lengthy have you

ever been blogging for? you make blogging look easy. The full glance of your

web site is magnificent, as smartly as the content material!

This is a nice blog i must say, I usually i don’t post remarks on other sorts of blogs

however would like to say that this post really forced me to do so!

Hey buddy, This was a superb post for such a tough topic

to discuss. I look ahead to seeing many more outstanding posts like this one.

Many thanks.

Admiring the time and energy you put into your website and detailed information you present.

It’s good to come across a blog every once in a while that isn’t the same old rehashed information. Amazing post!

I’ve bookmarked your website and I’m adding your RSS feeds

to my Google account.

Quality articles or reviews is the important to attract the people to pay a visit

the web site, that’s what this web site is providing.

Hello. I noticed your site title, ” Please don’t forget to add drafts when designing a plastic product” doesn’t really reflect the content

of your website. When creating your website title, do

you think it’s best to write it for Search engine optimization or for your audience?

This is something I’ve been battling with due to the fact I want good search rankings but at the same time I want the best quality for my site visitors.

thanks for your suggestion, but you know, we just want to tell a professional problem, as for the rest you said in this comment, we consider them very little

You’re so great! I don’t suppose I’ve learned anything like this before.

So nice to find anybody with some authentic thoughts on this subject.

really thank you for opening this up. this web site is something that’s wanted on the web,

someone with a little bit creativity. very helpful job for

bringing something totally new to the internet!

You must indulge in a contest for one of the finest blogs

online. I’ll suggest this site!

sbobet

This design is steller! You certainly know how to keep a reader entertained.

Between your wit and youur videos, I was almost moved

to start mmy own blog (well, almost…HaHa!) Excellent job.

I really loved what you had to say, and more than that, how

you prfesented it. Too cool!