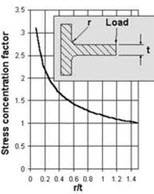

There are many many sharp corners in every plastic product, what does a sharp corner mean? Sharp corners greatly increase the stress concentration during injection molding.it could lead to failure of plastic parts, especially for the high amount of stress concentration. So generally, as a mold or plastic produce designer, when he or she meet that kind of sharp corner, they need to be radiused, The stress concentration factor varies with radius, for a given thickness. Do you know how to evaluate it?we will discuss it in the next time.

The sharp corners should be avoided in the plastic parts, as it can impede from plastic melt flow, causing flaws on parts. Meanwhile, stress concentration can be easily generated in the sharp corners and further reduces the strength of parts. Therefore, adding radii in sharp corners is suggested. There are 3 design tips about adding radii.

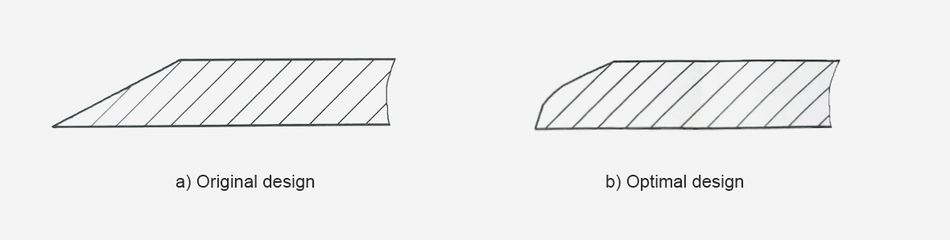

1. The outside sharp corners

The design of outside sharp corners is as the figure.

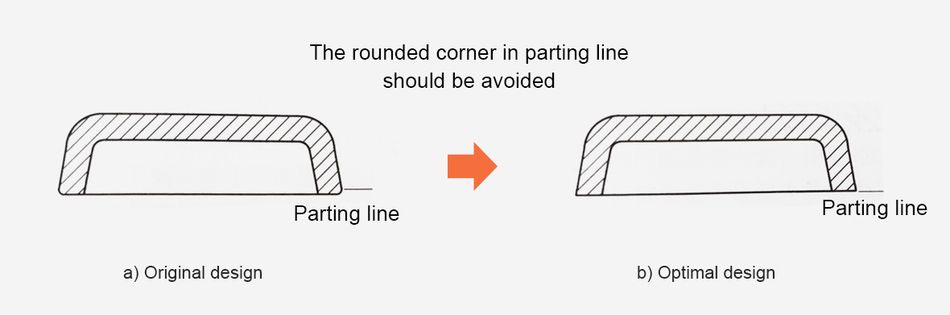

Of course, not all outside sharp corners should have radii. For example, the rounded corners in the parting line could complicate the mold configuration, increase the mold cost, make the breakage, and impact the appearance. The sharp corner in parting line of the parts is suggested.

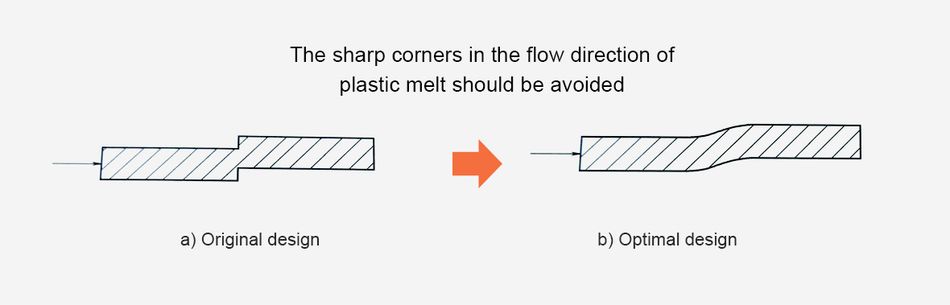

2. The sharp corners in the flow direction of plastic melt

The arrow direction in the figure is the flow direction of the plastic melt. In the original design, the sharp corner can easily cause trapped air during the injection molding, the local high temperature may degrade the parts, causing appearance defects. Adding radii is suggested to ensure the flow of plastic melt.

3. The sharp corners in the joints of wall

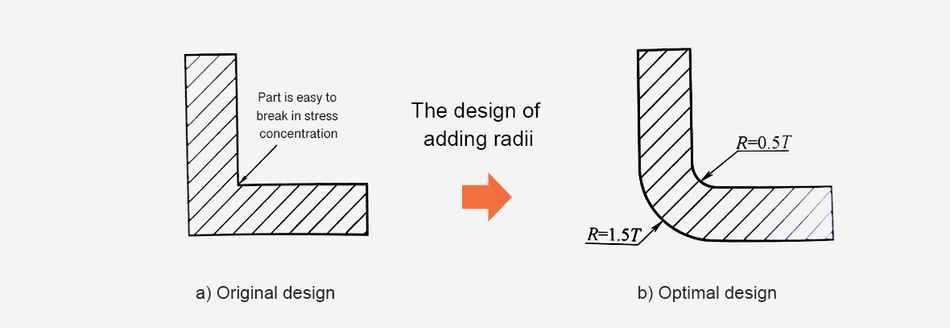

Stress concentration are likely generated in the sharp corners of parts. And sharp corners are easily appeared in the joints between the main wall and side wall of the parts, the joints between wall and ribs, and the joints between wall and pillars.

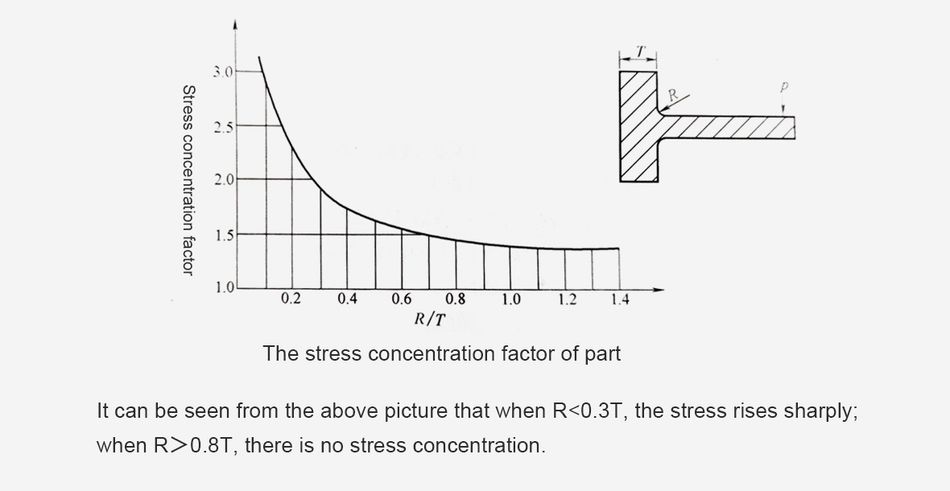

The relationship between the sharp corners and the stress concentration factor is shown in the below figure (T=Wall Thickness, R=Radii, p=the load borne by the part)

The inside radii in joints of part section should be 0.5T, and the outside radii should be 1.5T. This is to ensure the uniform wall thickness and reduce the stress concentration in part joints, as shown in the figure. Of course, the radii should not be too big, otherwise it may cause the thick wall, and generate shrinkage.

Sharp corners greatly increase the stress concentration.This high amount of stress concentration can often lead to failure of plastic parts.Sharp corners can come about in non-obvious places. Examples of this are a boss attached to a surface, or a strengthening rib. These corners need to be radiused just like all other corners. The stress concentration factor varies with radius, for a given thickness.

The stress concentration factor is quite high for R/T values lesss than 0.5. For values of R/T over 0.5 the stress concentration factor gets lower.The stress concentration factor is a multiplier factor, it increases the stress.

Actual Stress = Stress Concentration Factor K x Stress CalculatedThis is why it is recommended that inside radiuses be a minimum of 1 x thickness.

In addition to reducing stresses, fillet radiuses provide streamlined flow paths for the molten plastic resulting in easier fills.

Typically, at corners, the inside radius is 0.5 x material thickness and the outside radius is 1.5 x material thickness. A bigger radius should be used if part design will allow it.

Sharp corners greatly increase stress concentration, which, when high enough, can lead to part failure. Sharp corners often come about in non-obvious places, such as a boss attached to a surface, or a strengthening rib. The radius of sharp corners needs to be watched closely because the stress concentration factor varies with radius for a given thickness. As illustrated in the chart to the left, the stress concentration factor is high for R/T values less than 0.5, but for R/T values over 0.5 the concentration lowers. The stress concentration factor is a multiplier that greatly increases stress. It is recommended that an inside radius be a minimum of one times the thickness.

In addition to reducing stresses, the fillet radius provides a streamlined flow path for the molten plastic, resulting in an easier fill of the mold.

At corners, the suggested inside radius is 0.5 times the material thickness and the outside radius is 1.5 times the material thickness. A bigger radius should be used if part design allows.

Geometry plays a very important role. You have to balance aesthetic and functionality, keeping in view manufacturability: sharpness increases molding difficulty, tool wear, and risk of defects.

Geometry includes everything: part shape, features like ribs, bosses, holes, parting lines, draft, and wall thickness transitions. How these geometries relate will determine if corners are practical or need special treatment. E.g., placing a sharp edge near a rib intersection or near a gate may cause localized fill or cooling problems.

From a Design for Manufacturing (DFM) perspective, assume all internal and external corners will have fillets unless function dictates otherwise. DFM pushes for consistency in radii across similar features to avoid unpredictable variation.

You should also evaluate tool machining capabilities. Sharp internal corners often require EDM; very small fillets or very sharp external corners increase tooling cost and wear. The DFM practice is to design corners in ways compatible with standard milling/EDM capabilities to reduce costs.

Sharp corners may give a design a defined look, but in some manufacturing processes, they may signal trouble. Injection molding is one of the clearest examples where sharp edges add more problems than benefits.

If you had closely looked at molded plastic parts, you may have noticed that sharp edges are rarely present. That’s not an oversight but a deliberate design decision made based on molten material flow, cooling rate, and interaction with the mold.

I want to explore the challenges of adding sharp corners in injection molding, the main types of corners on injection molded parts, and the design rules that help create aesthetically and structurally good plastic parts.

Designing for injection molding, especially sharp cornered parts, is a precise engineering task. It often requires multiple revisions, simulations, and trial runs before achieving the right balance between manufacturability and performance.

Sharp corners create areas of high stress concentration, which can lead to part failure or reduced durability. The stress concentration factor is particularly high when the radius-to-thickness (R/T) ratio is less than 0.5. This concentration of stress can significantly weaken the part, especially under load or impact.

Difficulties in Mold Filling:

Sharp corners impede the flow of molten plastic during the injection process. That will lead to incomplete filling of the mold cavity and short shots. Trapped air pockets will cause voids or surface defects. Local high temperatures may degrade the material. Injection pressure requirements will be increased.

Ejection Problems:

Parts with sharp corners are more likely to stick to the mold during ejection. This can cause damage to the part during removal. The cycle time will be increased due to difficult ejection. And the mold will easy to wear and tear.

Increased Risk of Part Failure:

The combination of stress concentration and potential molding defects significantly increases the risk of part failure. This is particularly true for materials sensitive to stress during molding, such as nylon and polycarbonate.

Reduced Impact Strength:

Sharp corners dramatically reduce a part’s ability to withstand impact loads. For example, increasing the inside corner radius from 0.010 inch to 0.020 inch can notably improve impact strength.

The radius on corners has two primary functions. It improves the flow of the melt around a corner, which allows a cavity to be filled at lower injection pressure. This, in turn, results in less molded-in stress throughout the part. Corner radii also make molded parts stronger by distributing any stress on the corner over a broader area on the part. In other words, there is more plastic material to absorb the load.

Sharp corners often lead to defects and stress concentration in plastic parts, which can cause fractures under load or impact. Larger rounded corners (fillets) offer a solution to this problem. They not only reduce stress concentration but also facilitate smoother flow of the plastic during molding and easier ejection of the finished product.

If the internal corner is rounded and the external corner is sharp, the area at the turn will still be thicker than other parts, leading to shrinkage. A solution is to round both internal and external corners to achieve uniform wall thickness. In this case, the external radius is the sum of the internal radius and the base wall thickness.

The design principles for corner radii also apply to cantilever snap-fits. In these snap-fits, the cantilever arm needs to bend and fit into place. If the radius of the corner (R) is too small, it can lead to excessive stress concentration, making the product prone to breaking when bent. Conversely, if R is too large, it can result in shrinkage marks and voids. Therefore, there is a specific ratio between the corner radius and wall thickness, typically ranging from 0.2 to 0.6, with an ideal value around 0.5.

Sharp corners have their purpose – but they’re incredibly difficult to make with injection molding. That’s where radius design comes in when creating the mold for your part. So, what is a radius, and why is it important?

WHAT IS A RADIUS?

A corner radius (corner radii if there is more than one) is a technical term for smoothing out or rounding any sharp corner in a design. Internal radii are used for inside corners and external radii are used on outside corners. The general rule is to use a radius equal to at least 0.5 times the adjacent wall thickness.

FILLET RADII

An internal radius is also called a fillet radius. They are designed into molds to improve the quality of the part, increase load-bearing strength, and improve the injection molding process. Fillet radii are usually found on inside corners or the bottom of a compartment, and they can be used between ribs, bosses, and gussets to connect them to walls for better strength.

ROUND RADII

An external radius is called a round radius. It’s the rounding of outside corners for the same purposes as fillet radii.

WHY IS RADIUS DESIGN IMPORTANT?

While rounding out sharp corners makes a part easier to handle, incorporating radii into your design also helps improve the quality and stability of your part. Why?

Due to the way that molten plastic fills a mold, it’s incredibly difficult to fill sharp corners in a mold. External radii help make sure the whole mold is filled, ensuring better part quality.

Additionally, as a part cools, it shrinks. If it has to shrink around a sharp angle, it adds additional stress to the part that can lead to cracking.

For these reasons, it’s also important for sharp corners at the base of ribs, bosses, and gussets to have a radius design, since they help to offset stress points.

The sharp corners should be avoided in the plastic parts, as it can impede from plastic melt flow, causing flaws on parts. Meanwhile, stress concentration can be easily generated in the sharp corners and further reduces the strength of parts. Therefore, adding radii in sharp corners is suggested.

actually this is a plastic product design detail, sometimes this rule need to be considered carefully on some areas

This is a principle of plastic product design.

yes!This is a basic rule of plastic product design if it needs to make mold

this is an important suggestion on plastic product design or injection mold design

Thank you for reminding me

believe it or not, some mold designers or product designers often forget this rule

I understood what you are talking about!

This is a basic design rule in a plastic product design

Thank you for reminding me

I always do like this, don’t worry!:-)

your suggestion is correct!:-)

this is a design rule as every product designer knew

thanks for sharing your experience on this issue

This is a basic design rules

Good experience

as an injection molding engineer, I always remind our mold designers not to neglect it

thanks for sharing your experience

Please write more, so that we can discuss

your experience on this issue is correct,

I agree you at all.

thanks for sharing your experience

your opinion is correct

sometimes at certain area on certain product, it is difficult to decide

sometimes it depends on your product.

In most cases, your suggestion is correct

This blog will be useful for many primary mold designers

you are actually an excellent webmaster. thanks for sharing your experience on plastic product design

This is a design criterion in product design and mold design

this is a rule every plastic product designer should observe

as a mould designer, I understand your opinion.

your suggestion is very useful for our mold designers

good suggestion! it will help flowing during injection molding

good experience! thanks for sharing

some sharp corners on some plastic products are not allowed to be radiused

yes! it will help the flow of the molten resin

as an industrial designer,your blog is very useful for me, You have done an outstanding job!

Normally, this is right, unless it has special requirement

thanks for sharing your experience.

yes! Rounded corners are good for the molten plastic flow

good suggestion! but I want to say sometimes it depends on product’s requirement

Hello it seems that you are right, but at the certain view, maybe Your opinion is inadequate. in our industry,Nothing is absolutely the same

Ahaa, its fastidious discussion concerning this piece of writing here at this weblog, I have read all that,

so now me also commenting here.

It’s difficult to get well-informed people on this topic yet you sound like

you know what you’re speaking about! Many thanks for this post.

I definitely agree with what you are saying.

Keep us posted.

I’m really enjoying the design and layout of your site.

It’s a very easy on the eyes which makes it much more enjoyable for me to come

here and visit more often. Did you hire out a developer to

create your theme? Fantastic work!

I like what you guys tend to be up too. This sort of clever work and exposure!

Keep up the wonderful works guys I’ve added you guys to my personal blogroll.

Hi there to every one, it’s genuinely a good for me to pay a quick visit this website, it consists of helpful Information.

Great post. I used to be checking continuously this blog

and I am impressed! Extremely useful information specifically

the remaining part :) I deal with such information a lot.

I used to be seeking this particular info for a long time.

Thanks and best of luck.

Great post. excellent website, professional company, good luck!

First of all I want to say excellent blog! I had a quick question that I’d like

to ask if you do not mind. I was curious to know how you center yourself and clear your

mind prior to writing. I’ve had a tough time clearing my thoughts

in getting my thoughts out. I truly do enjoy writing however it just seems like the first 10 to 15 minutes

are lost simply just trying to figure out how to begin. Any recommendations

or hints? Thank you!

thanks for visiting firstratemold.com as for writing issue, one advice I can provide is to write more and practise more

I have been exploring for a bit for any high-quality articles or blog posts

on this sort of space . Exploring in Yahoo I ultimately stumbled upon this site.

Studying this info So i’m satisfied to exhibit that I’ve a very good uncanny feeling I discovered exactly what I needed.

I such a lot undoubtedly will make sure to do not omit this site and provides it a look on a continuing basis.

Excellent post however , I was wondering if you could write a litte more on this subject?

I’d be very grateful if you could elaborate a little bit more.

Appreciate it!

Superb blog you have here but I was wondering if you knew of any

discussion boards that cover the same topics discussed in this article?

I’d really love to be a part of community where I can get responses

from other experienced individuals that share the same interest.

If you have any recommendations, please let me know.

Thanks a lot!

thanks! are you interested in discussing with us?

I’m not sure where you’re acquiring your information and facts, however excellent topic.

I must spend some time learning or understanding more. Thanks for wonderful information. I was trying

to find this info.

Hi there, You’ve done a great job. I’ll certainly digg

it and personally recommend to my friends. I am sure they

will be benefited from thbis web site.

I read this article fully about the resemblance of latest and earlier technologies, it’s remarkable article.

I do accept as true with all the ideas you have presented on your post.

They are very convincing and can definitely work. Nonetheless, the posts are too short for novices.

Could you please extend them a bit from subsequent time? Thanks for the post.

we welcome every one who is interested in every topic adds more details she(he) knows, so that we can discuss each other

Your mode of explaining the whole thing in this post is in fact nice, all be capable

of simply be aware of it, Thanks a lot.

I like it when individuals come together and share ideas.

Great blog, continue the good work!

I enjoy reading a post that makes individuals

think. In addition, thanks for permitting me to comment!

Saved as a favorite, I like your blog!

Wow, marvelous blog layout! How long have you been blogging for?

you make blogging look easy. The ovrrall look of your

site is magnificent, as well as the content!

Thanks for a marvelous posting! I quite enjoyed reading it, you

can be a great author.I will make certain to bookmark your blog and will come

back from now on. I want to encourage that you

continue your great posts, have a nice day!

Hi there mates, good article and nice arguments commented at this place, I am truly enjoying

by these.

Hey there would you mind sharing which blog platform you’re working

with? I’m looking to start my own blog in the near future but I’m

having a tough time deciding between BlogEngine/Wordpress/B2evolution and Drupal.

The reason I ask is because your design and style seems different then most blogs

and I’m looking for something unique. P.S Apologies for being off-topic but I had to ask!

we are using Workpress platform in our website!

Hey there! My spouse and I often write guest articles or blog posts for other weblog owners to help increase exposure to our

work, as well as provide good articles to website owners.

It really is a win win situation! If you happen to be interested feel free to email

me at: jerilynbalas@googlemail.com so we can communicate

further. Thanks!

we sent an Email to you, please response. thanks!

Hello! Wonderful post! Please keep sharing simply because

I’ll be staying tuned for more!

Hello there, had alert to your blog through Google, and found that it’s truly enlightening.

I’ll be grateful if you continue this in future.

Thank you for your really good information. They are very valuable.

Good day I am so thrilled I found your site, I really found you by accident, while

I was browsing on Askjeeve for something else, Anyhow I

am here now and would just like to say thank you for a marvelous post

and a all round interesting blog (I also love the theme/design), I don’t have

time to read through it all at the minute but I have bookmarked it and also added your RSS feeds, so when I have time I will be back to read a great deal more, Please do keep

up the great b.