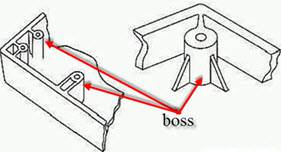

Boss design is a common design in a plastic part, it is used for mating part or for attaching fasteners such as screws or accepting threaded inserts. if our engineers design a bad boss in a plastic part, we will meet many molding problems, so I think The wall thicknesses of a boss should be less than 60 % of nominal wall. of course, it depends on the boss’ position in a plastic part, if it is in an unimportant or invisible position, the wall thickness can be increased a little. even can be used self-tapping screw, a greater radius at the base would be better, a least 0.25 x thickness. Gussets or connecting ribs reinforce the boss.

Bosses are common structures on plastic parts in home appliances and interior and exterior of automobiles, mainly for positioning and fastening.

The base of bosses often cause sink marks on the back surface of a part, this is because of the large wall thickness. The solution is to core out some material at the base,

There are two additional points to consider in designing bosses. As mentioned earlier, a boss is a circular rib, and like any rib, its walls—both inside and out—must be drafted to facilitate ejection. Depending on the height of the boss, this draft can be anywhere from a half degree to 3 degrees. If draft of the inside diameter of the boss is not acceptable, the boss can be molded as a solid and the inside diameter drilled, by you, as a secondary operation. Also, because a boss is formed by a blind hole in the mold body, we may have to add vent pins to the rim of the boss to allow the escape of trapped gas during mold filling. Otherwise shorts or burns may form on the rim.

Many part designers have studied mechanical engineering and used mainly metals in their design work. The necessary differentiation by designing a metal or plastic part is therefore a lot of times unknown. However, it is truly mandatory, as the correct design of the plastic part saves material, cycle time and therefore money. A plastic part design makes the cooling of the mold easier, because less hot spots will appear. Furthermore, the first trial will be more successful, because less defects will be visible at the part, which need to be corrected.

The design and placement of bosses is critical in injection moulding. As with all injection moulding, shrinkage is a major consideration. Shrinkage looks bad, and more importantly if shrinkage affects your bosses then they might not align properly causing delays in assembly.

The important things to look out for are:

– The thickness of the boss should be 60% or less of the parts nominal wall thickness.

– Bosses need to be tied in place with ribs and fillets, to prevent warping.

– The Internal diameter of screw bosses should be slightly less than the screw thread and their length should provide at least 60% of the screw thread with something to catch on.

Bosses serve two purposes. Their primary use is to strengthen holes or slots in the surface of your part. Plastics designers love thin walls, but thin and strong are opposites ends of the trade-off spectrum. Bosses are the happy medium, reinforcing fracture prone features like screw holes, penetrations or mounting slots without impacting the cost or looks of a design.

The secondary use of bosses is to create points at which your assembled product can be fastened together. Injection moulding is all about speed, and not just in the actual moulding. Properly designed plastic parts bring down costs by being designed for rapid assembly. Take apart a high quality plastic product, and it should be easy to put it back together again. The bosses should line up and show you how parts fit, and then those bosses should hold the parts in place, ready for a fastener or clip to permanently fix them in place.

I think the experience about this design detail is very helpful, I got it

I will recommend your blog to our mold designers, it will absolutely benefit them

I had ever met that kind of problem before, now after reading your blog, I agree you at all

thanks for sharing, I got it

your experience on this topic is very good, I got it

thanks for sharing

thanks for sharing your experience

your suggestion is correct, thanks for sharing

your sharing is very good, thanks!

yes! it is very important.

I appreciate your sharing

please share more detail on this issue,it will benefit more professional guys!

thanks for sharing your experience on plastic product design

Great blog ! I apprentice your sharing

These are just the tips in mold design or plastic product design

I bet your guy is just a good mold designer

maybe some mold designers or product designers need your experience

your suggestion is correct, I got it, thanks!

I understand your meaning, yes! it is very important

You seem to deeply understand plastic molding, You are a very experienced designer

Hello my friend, I agree what you desire to say on the topic of this

article, it is very useful, thanks for sharing

Awesome post many thanks! We think your content articles are fantastic and hope there’ll be more soon.

Outstanding story there. What happened after?

Good luck!

Hi. I found your blog utilizing msn. This is a perfectly written post.

I will be sure to bookmark it and return to read more of your useful information. Thank you for the post.

I will definitely return.

What’s up, I want to subscribe for this weblog to obtain hottest

updates, so where can i do it please help.

at present, one thing you can is to bookmark or link firstratemold.com if you are really interested in it

Thanks for writing this great excellent articles. The information in this material

shows my viewpoint and you actually laid it out well.

I could never have written a piece of writing this great.

Great information, better still to discover your blog that has a fantastic layout.

Nicely done

Hello! I have to admit, I’m impressed with your site. I had no trouble navigating through all

the information. I found what I wanted in no time at all.

Pretty great. Would appreciate it if you add forums or something like that, it would be

a great means for your clients and various other visitors to interact.

Well done.

Greetings I’m so delighted I find your site, I actually found you by mistake, while I was searching on yahoo and google for something else, Nonetheless I am here now and could just

like to say many thanks for a tremendous post as well as enjoyable website.

Please do continue the truly amazing work.

It’s going to be finish of mine day, but before end

I am reading this great paragraph to increase my know-how.

I relish, cause I found exactly what I used to be taking a look for.

You have ended my 4 day long hunt! God Bless you man. Have

a great day. Bye

I know this site presents quality dependent articles and

other stuff, is there any other website which offers these things

in quality?

Great blog here! Also your web site loads up very

fast! What host are you using? Can I get your affiliate link to your host?

I wish my web site loaded up as fast as yours lol

Great post. I was checking continuously

this blog and I am impressed! Very useful information particularly

the last part :) I care for such info much. I was looking for this particular information for a very

long time. Thank you and good luck.

Hello, your website is really good. I really do appreciate you sharing helpful posts.

Way cool! Some very valid points! I appreciate yyou penning

this write-up and also the rest of the website is extremely good.

Nice to be visiting your blog once more. Good

this post. Thank you for sharing.

Thanks for your marvelous posting! I seriously enjoyed reading it,

you may be a great author.I will always bookmark your blog and definitely will come back from now on.

I want to encourage you to definitely continue your great posts, have

a nice morning!

I’m impressed, I have to admit. Seldom do I encounter a blog

that’s both equally educative and interesting, and let me tell you, you have hit the nail on the head.

The issue is something that too few people are speaking intelligently about.

I’m very happy that I stumbled across this in my

search for something regarding this.

Hey there i just visited your web site for the very first time and i really liked it, i saved it and will

be back.

Amazing! This can be one of the most useful blogs I

have ever arrive across on this subject. Actually this is great.

I’m also an expert in this topic so I can understand your hard work.

yes! the plateform we are using is called WordPress!

I truly love your site.. Pleasant colors &

theme. Did you create this website yourself? Please reply

back as I’m wanting to create my very own website and would love to find out where you got this

from or just what the theme is called. Thank you!

I have loaded your website in Several different internet browsers and I must say this blog loads a lot faster then most.

Would you mind emailing me the company name of your hosting

company? My personal e-mail is: caseydoolittle@gmx.net.

I’ll even sign up through your own affiliate link

if you’d like. Many thanks

we shot an Email to you, please check.

Howdy! I could have sworn I’ve been to your blog before but after going through some of the

articles I realized it’s new to me. Anyhow, I’m definitely pleased I stumbled upon it and I’ll be book-marking it and checking

back frequently!

Wow that was strange. I just wrote an extremely long comment but after I clicked submit my

comment didn’t show up. Grrrr… well I’m not writing all that over again. Anyways, just wanted to say excellent blog!

Hello to every one, it’s actually a good for me to pay a quick visit this

website, it contains useful Information.

Have you ever considered concerning adding a little bit more than just your articles?

I mean, what you say is basic and everything. Nonetheless

think about if you included some terrific pictures or video clips to give your

posts more, “pop”! Your content is outstanding however with

images and clips, this website could certainly be one of the most beneficial in its

field. Great blog!

You offer an important information. I’ll be your regular website visitor.

Many thanks for this outstanding write-ups. Keep sharing excellent articles!

It’s hard to come by knowledgeable people about this subject, but youu sound like you

know what you’re talking about! Thanks