FMS Mold Engineering Service Is A Value-added Service

As the mold technology and experience of FMS Team have been recognized by more and more customers, we have begun to accept our customer’s mold manufacturing projects.

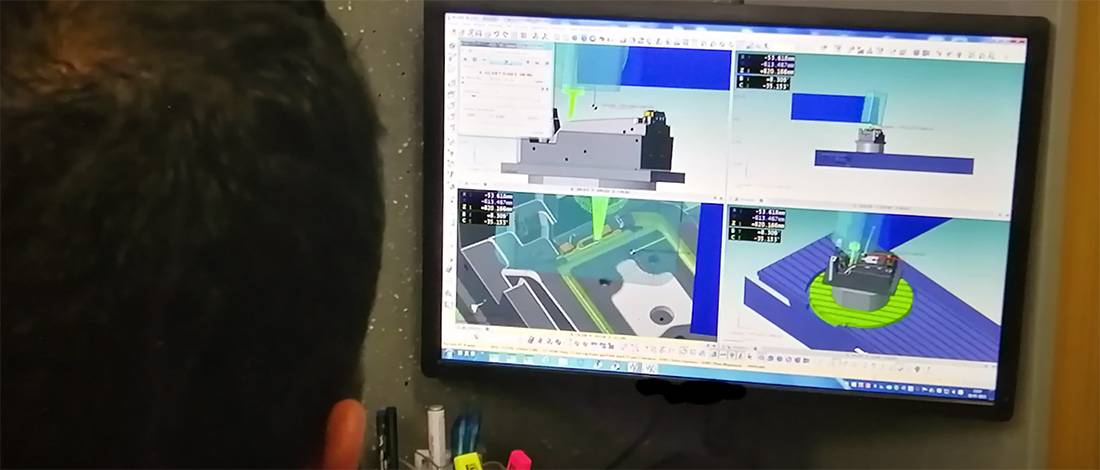

Collaborative Mold Engineering: Now we have realized collaborative mold engineering through the Internet. You can view our mold making and assembly and mold tryouts online at any time, just as if we were working in your molding shop or mold shop or engineering department. Our customers are very satisfied.

Our operating model is very different from the operating models of mold companies that directly accept outsourced mold manufacturing projects. Our team directly represents our customers to strictly supervise and guide the mold manufacturers, so that the customer’s molds can completely meet the requirements of our customers.

We have two types of customers

1) The customer’s molds are designed by FMS designers. The advantage of this type of order is that we are very familiar with these molds that need to be manufactured by outsourced plant and their technical requirements.

2) The customers directly send their mold designs to FMS Team. We need to learn their mold designs, and deeply communicate with the customer’s designers and keep communication at any time.

The core of FMS Mold Engineering Solution is that we stand on the side of our customers and ensure the interests of our customers to the maximum

FMS Mold Engineering Solutions:

- When we receive the mold manufacturing order entrusted by our customers, after we understand the design and technical requirements of the entire mold, our engineers begin to find suitable mold manufacturers in China, and then go to the factory for field inspection and communication, When the candidate mold manufacturers are confirmed, we will ask them to quote the molds. After FMS Team evaluates and confirms their quotations, we will send them to the customer for confirmation

- When our customers confirm the quotation and let the mold manufacturers start manufacturing, FMS will fully represent our customers to the outsourcing mold companies to sign an agreement with them and send engineers to their mold workshop to follow up the mold manufacturing. Weekly report the progress of the molds to the customers and handle the accidents about the mold manufacturing at any time.

- When the molds are finished try-out,our engineers will faithfully write the test report, the evaluation of the molds and the improving suggestions, and report to our customers in time to ensure that the molds fully meet the design requirements.

- When the molds are to be delivered to our customers, our engineers will perform a final inspection of the molds to ensure that all the molds fully meet the customer’s requirements.

Why does your mold need to be outsourced?

1)If you are a production company of products, then you will lack the professional knowledge of the mold making,you need mold outsourcing.

2)If you are a mold company and you receive a mold order that you are not good at manufacturing, you need mold outsourcing.

3)If you receive a mold manufacturing order that exceeds your capacity, you need mold outsourcing

4)Outsourcing mold project allows companies to take full advantage of the extensive processes and resources available, such as:

Automated plastic injection molding equipment / Skilled design, engineering, tooling, and processing staff / Thorough molding equipment maintenance / Production-support employees

Why can’t you buy a good mold in China?

After 40 years of rapid development, China’s mold industry has been greatly developed, and the mold design and manufacturing level has been greatly improved. In some aspects, our level has even approached the level in Europe and the United States. But why can’t you buy a good mold in China?

We often see foreign customers who come to China with their own mold projects to find local suppliers. Their purpose is to find lower prices. If which mold company offers the lowest price, he will get these orders. Yes! compared with the mold quotation in Europe and the United States, the mold quotation in China is indeed quite low, but in your mind, Do you really know how much it costs to make a mold that meets your requirements in China? Do you really know China’s mold industry better than Chinese mold engineers? So our suggestion is to hand over your mold project to FMS Team, we will give you a good mold and guarantee the price of China.

Mold shaping or mold engineering is of central importance in production. It includes designing and manufacturing molds used to produce different parts and products. These molds need to be very specifically made, so the final product may meet quality standards. Let’s take a look at what mold engineering is and why it is so vital to many industries.

The Basics of Molding

Molding is a technique of using molds to create products from raw materials. It is an essential practice in manufacturing and is used for producing parts from metals, plastics, and more. Mold engineering is indispensable in manufacturing, as it necessitates designing these molds to incredible accuracy, requiring detailed know-how and advanced equipment.

The Role of Precision in Mold Engineering

That is why precision in mold engineering is imperatively non-negotiable. Everything is based on precise measurements and careful design so that the molded components are able to achieve the proper tolerances and function properly. Precision molds are constructed to reduce errors, error tolerance, quality control, and longer mold usability.

Benefits and Importance of Precision Molding

The precision in mold engineering provides several benefits. Be it improving productivity or better product quality, precision is directly proportional to efficiency and effectiveness of the manufacturing processes. Here, we discuss a few of the benefits of precision in mold design and production.

Improved Quality and Performance

Precision molds are needed to create exceptional parts that meet high specifications Following accurate measurement allows manufacturers to prevent common defects, including warping, dimensional inconsistency, and poor surface finishing. This precision molding means that each piece has the same shape, which greatly enhances the overall performance of the finished product.

Cost Efficiency and Waste Reduction

Because precision molds minimize the chance of defects and scrapped parts, they can save money for manufacturers. Designing molds that produce accurate end goods from the beginning eliminates costly modification and rework for companies. This saves money and conserves materials allowing for more sustainable manufacturing practices.

Enhanced Durability and Longevity

High quality precision molds also have better durability and longer lifetimes. And through careful design and selection of tougher materials, molds are designed to withstand the grueling demands of production and to not become worn down after just a few uses. This durability directly contributes to less downtime and lower maintenance costs, reinforcing the economic advantages of precision mold engineering.

Key Considerations for Successful Mold Engineering:

Cost Efficiency and Waste Reduction:

Optimize the design to minimize material usage and manufacturing time.

Material Compatibility:

Ensure the mold and molded part materials are compatible to prevent corrosion or other issues.

Long-term Mold Life:

Design the mold to withstand the rigors of the molding process and maximize its lifespan.

Repeatability and Reliability:

Strive for a robust mold design that produces consistent, high-quality parts with minimal defects.

Communication and Collaboration:

Maintain open communication between designers, engineers, and manufacturers to ensure a successful outcome

The creation of the mold is the initial step in injection molding. Most molds are finely machined from metal, usually aluminium or steel, to suit the aspects of the product they will manufacture.

The material for the part is injected into a heated barrel and combined using a helical curved screw after the mold has been made by the mold maker. The substance in the barrel is melted by heating bands, and the liquid metal or plastic is then injected into the mold cavity, where it chills and solidifies to match the mold’s structure.

The use of chilling lines that disseminate water or oil from an exterior temperature controller helps shorten the cooling period. Mold tools are installed on plate molds, which separate once the substance has solidified and remove the item from the mold using ejector pins.

A two-shot mold is a type of injection molding that allows different materials to be blended into one component. This method can be used to provide plastic items with a softer feel, to colour a part, or to create objects with varied performance capabilities.

Single-cavity or multiple-cavity molds are available. Each cavity of a multiple cavity mold might have similar pieces or be distinct to generate parts with diverse geometry. Owing to the injection and clamping forces, aluminium molds are not recommended for high volume manufacturing or products with tight dimensional forbearance since they have poor mechanical qualities and are vulnerable to wear, distortion, and breakage. Steel molds are more robust than aluminium molds, but they are also more costly.

The structure and characteristics of the component, the materials for the component and the mold, and the attributes of the injection molding machine all demand careful design in the injection molding procedure.

Injection molding is a very efficient and widely used plastic manufacturing process for producing parts in large quantities. Mold development is a critical aspect of this process, essential for accurately shaping and forming molten plastic with high precision. The creation of molds, as one of the first steps, demands great precision and accuracy to ensure the quality and consistency of the final products.

There are various ways to classify molds in injection molding, including by plate type, runner type, cavity design and class. Among these classifications, mold cavity design—single-cavity, multi-cavity, and family molds—plays a pivotal role in determining production efficiency and quality. Single-cavity molds are simpler and offer high-quality parts, ideal for low-volume production and intricate designs. Multi-cavity molds enhance production speed and reduce the cost per part for large volumes, but require precise balancing to avoid defects. Family molds allow for the simultaneous production of different parts, optimizing manufacturing for multi-part products but increasing design complexity and the potential for defects.

The creation of the mold is the initial step in injection molding. Most molds are finely machined from metal, usually aluminium or steel, to suit the aspects of the product they will manufacture.

The material for the part is injected into a heated barrel and combined using a helical curved screw after the mold has been made by the mold maker. The substance in the barrel is melted by heating bands, and the liquid metal or plastic is then injected into the mold cavity, where it chills and solidifies to match the mold’s structure.

The use of chilling lines that disseminate water or oil from an exterior temperature controller helps shorten the cooling period. Mold tools are installed on plate molds, which separate once the substance has solidified and remove the item from the mold using ejector pins.

A two-shot mold is a type of injection molding that allows different materials to be blended into one component. This method can be used to provide plastic items with a softer feel, to colour a part, or to create objects with varied performance capabilities.

Single-cavity or multiple-cavity molds are available. Each cavity of a multiple cavity mold might have similar pieces or be distinct to generate parts with diverse geometry. Owing to the injection and clamping forces, aluminium molds are not recommended for high volume manufacturing or products with tight dimensional forbearance since they have poor mechanical qualities and are vulnerable to wear, distortion, and breakage. Steel molds are more robust than aluminium molds, but they are also more costly.

The structure and characteristics of the component, the materials for the component and the mold, and the attributes of the injection molding machine all demand careful design in the injection molding procedure.

The steps involved in starting a plastic injection mold engineering business are straightforward and irreversible.

Researching the market. Find out if industries around you or people in your locality need the service that you are about to offer. Know the exact products that they need and don’t forget to look out for the competition around you.

Assessing the demand for industrial goods and their costs. Medical and fitting line products are currently in high demand, with minimal need for agricultural-based products. It’s important to keep in mind that demand varies from place to place and throughout time.

Selecting the Right Injection Moulding Machine (you can explore directly on the net there are plenty of dealers which can help u in finding the right machine for you).

Selecting a reputable mold maker. A local mold maker will build a mold for a low price, but it may begin to flash in particular strokes. Professional mold manufacturers will cost nearly twice as much as local mold makers. Make sure your plastic mold makers use adequate and quality materials when creating the mold. If the mold has faults, it will harm the clamping unit of the machine, reducing its life.

Locating your provider of raw materials. If you are using higher tonnage machines that consume a large amount of plastic, a reliable raw material supply is required. The demand for these products will be high across the country. Also, keep in mind that these products are difficult and expensive to transport in large quantities.

Assigning the appropriate industrial area.

Assembling the compressor, as well as the injection molding machine. In addition to the injection molding machine, the first startup requires a water chiller, dryer, air compressor, grinder, loader, conveyor, packaging robot, and other items, depending on your product and machine.

The detailed schedule for a project needs to be able to be managed efficiently and effectively. A well-oiled machine will have a visual schedule that can be read easily to know what is on schedule, what is behind, and what lies ahead to the end of the project. A Gantt chart is one way to manage the schedule, but it’s not the only way. Expect that a good tool production facility will be managed with detailed organization.

Injection molding is part of the project. Secondary services may be what you need to have a world-class product assembled, packaged and delivered to your customers. A tool facility just makes tools, but what if you need assembly, extra processing, quality testing and inspection for your product? Having a one-stop-shop that will take the stress of a new project off your hands is an important consideration. Choose the right manufacturing facility for your project from beginning to end.

Last, but not least is the overall quality of workmanship. The actual tool is only a portion of the experience in building an injection molding tool. You should be able to ask questions, have open discussions on timing and budget, and feel comfortable at each step of the process. If you leave a discussion feeling uneasy, maybe it’s time to keep looking for a new partner. Successful partnerships are based on trust.

Injection molds come in different shapes, sizes, and designs. It is important so that plastic products can be unique depending on the manufacturer. These designs are innovated by injection designers and executed by engineers. The engineers in plastic injection molds play a vital role in inspecting the designs before building to ensure that the molds are manufacturable. Thus, the engineers need to be experts in this field to avoid any errors and defects that may arise during mold manufacturing.

Building molds and operating the injection molding machines is not an easy task as some may assume. It requires a lot of expertise, critical thinking, and creativity. Before hiring designers and engineers at your company, you need to be sure that they are capable of completing different projects, moreover, are able to handle themselves under pressure.

Before you can manufacture a plastic part you need to have a solid design in place. Once done, you can build an injection mold to meet the product specifications.

The role of the Design Engineer is critical in this process. They assess the part design and make modifications and recommendations based on key product requirements including product usage and function. The engineer will need to know:

How will the part be used? Is it a standalone product or a component of a larger assembly?

What are the dimensional and tensile requirements?

Does the part need to withstand elements, pressure, chemicals?

A plastic injection mold design is built with these criteria in mind. Mold cavities, vents and gate placement will vary based not only on the part design but the type of resin as well. Taking all of these manufacturing factors into account is a challenging task and one that requires a strong knowledge base, not only of mold design but the injection molding process as well.

The allure of injection molding for manufacturing parts is due in large part to the versatility, speed, and quality of the finished molded parts. From the outside, these qualities appear to be inherent parts of the injection molding process, and because injection molding seems fairly straight-forward, many manufacturers consider scaling to bring the process in-house for their needs. But to maximize the benefits of the injection molding process, it requires a sizeable team of knowledgeable technicians and engineers operating high-end, large-scale equipment — a structure and process more easily found in a dedicated plastic injection molding manufacturer. Which is why, for manufacturers looking to get the best quality parts for their money, outsourcing injection molding needs makes the most financial sense.

GUARANTEED INFRASTRUCTURE AND ECONOMICS OF SCALE

As mentioned, the equipment necessary for injection plastic molding is both technically complex and physically imposing. Put simply, it’s costly. But investing in equipment alone only scratches the surface of what it financially requires to produce injection molded parts.

For instance, while the equipment is usually partially automated, only a dedicated team trained and experienced with the technology will be able to get it up-and-running on the near-constant cycles necessary to produce injection molded parts at scale. Those same cycles require a massive amount of power, as well as material and time, to run — all costs that will come out of a business’s bottom line. Additionally, considering the strain the molding machinery is under, a guaranteed amount of maintenance and down-time is be expected, meaning more dedicated service hours from specialized individuals to get the machinery up and running again.

All of these factors are built in to the business model of a dedicated plastic injection molding manufacturer, and the costs for any of them are negligible for their customers, because the injection molding manufacturer is able to spread them out over a larger swath of time, and a greater breadth of customer work.

Additionally, because the molding manufacturers’ operation is specifically injection molding, they are better equipped to reinvest and hone in on their core competency in the injection molding process, allowing for higher-quality products to be produced faster and more accurately, allowing for customer orders to be fulfilled with quicker delivery times and shorter times-to-market.

HIGHER QUALITY

Staying competitive in the plastic injection molding world requires dedication to quality production, produced at speed and scale. A respected outsourced injection molding manufacturer will have a team that is trained and certified, with years of expertise in the craft, as well as robust production support functionality to operate as an additional layer of insurance for the work they are producing.

Plastic injection molding providers are able to build out these additional functionalities because their resources stay focused on their core competencies. Supporting design, engineering, concepting, production, QA, and fulfillment allows the plastic injection molding manufacturers to work more closely with customers to fully realize the parts they are producing, without pulling focus from other areas of their business. This allows manufacturers to be involved at every step in the process, answering questions, providing guidance, and streamlining the process to save money, time, and re-work costs during the actual production runs.

Outsourcing injection molding capabilities is about more than saving money — it’s about maximizing the investment into making the best possible version of a product with efficiency, control, and quality results.

What’s the best mold-making technique for a given application? It depends on a couple of important factors, including the desired end-part material, the intended manufacturing process, the geometry of the model, and the production volume.

A simplified, step-by-step approach to choosing the best technique for your manufacturing project is covered in stages below:

1. Outline the Development Criteria for Your Project

A manufacturing master plan can help create clear-cut details of what is to be expected from a project, its development timeline, and the available budget. Whether you’re planning to create custom parts or mass-produce thousands of the same item will define what options to pick in the next steps. The development criteria might vary depending on the project, but generally include the design of the part, size, material, quality, required tolerances, timeline, required production volume, cost constraints, etc.

In product development, the initial document that answers many of these questions is often the product requirements document (PRD), while the bill of materials (BOM) is the comprehensive list of parts, items, assemblies, and other materials required to create a product.

2. Select the Manufacturing Process

The right manufacturing process for a certain part is largely dependent on the development criteria. In some cases, multiple production processes can be used to create any given design. As a rule of thumb, choose the process that can produce the given part with the required quality, at the lowest costs, while fulfilling the rest of the development criteria. The material choice and manufacturing volume are likely the most important factors driving your decision.

For plastic parts, you can read our guide to manufacturing processes for plastics.

3. Select the Mold-Making Technique

Once you settle on the right manufacturing process, the type of mold for the process is also largely defined by the development criteria. While the exact factors are dependent on the manufacturing process, here are some of the most important considerations when choosing a mold-making technique:

Design of the part: Try to simplify the design as much as possible and align it with the design rules of the given manufacturing process to be able to choose the technique that can achieve the lowest costs. Simple designs might only require molds that can be created with manual techniques, while complex designs often require multi-part molds and digital manufacturing tools like 3D printers or CNC machining to create.

Production volume: Large-volume production runs require durable molds that can accurately replicate models without wearing out after a few uses. However, fabricating such tools comes with high costs and lead times. For one-off parts and lower volume batches, it might be more efficient to choose cheaper molds that can be created faster, such as sacrificial molds or soft molds that can be discarded when they begin to show signs of irreparable wear.

Quality: Tighter tolerances require more precise molds and tools to create, such as digital manufacturing tools, and need to be more durable to ensure consistent part quality over multiple cycles.

Timeline: Producing complex metal molds often takes months through a service provider. If you’re working on a shorter timeline, try to look for alternatives that can shorten the lead time, such as 3D printed rapid tooling.

Material: Materials that have a higher melting point or are more abrasive will require molds that are more durable and can create the required volume of parts without degradation.

After reading this article, I want to share 10 important best practices in doing mold engineering.

1) Material choice: Producing high quality, consistent plastic injected modeled parts relies heavily on the chosen material. you can browse materials by name, type, performance, and characteristics. Another option is go directly to material manufacturers. Consider mixing materials. With today’s injection molding processes, you have the option to mix materials or include additives. Additives can be a way to enhance materials to meet your needs. One additive to consider is glass. Another is carbon fiber, which will add strength and static dissipation.

2)Appropriate wall thickness. Next to your material selection, maintaining a uniform wall thickness throughout your part is critical.

Wall thickness will often determine mechanical performance, cosmetic appearance, ease of molding the part, and the cost of the part.

3)Achieving an optimal wall thickness is a balance between strength and weight. A 10% increase in wall thickness provides about a 33% increase in stiffness with most materials. But avoid changing wall thicknesses within a design, going from thick to thin or from thin to thick over sections.

This will be mentioned later, but ribs and curves can provide strength to a part without resorting to increased wall thickness.

4)Draft. Draft is the angle designed into your part that aids part removal from the mold. Include draft in a design to prevent sticking an ejector pin push into your parts, especially on a cavity or show surface.

Draft, annuals, and tapers all ease a part out of mold during ejection. Less draft will sometimes damage parts during ejection, a condition known as drag, especially at the parting line.

A minimum recommended draft angle is a half a degree. A preferred draft angle is one and a half to two degrees, especially if you’re going to be adding textures.

5) Runners and gates should be designed and incorporated into a mold to ensure the consistent flow of material to fill the mold at the right pressure. A gate is the connection between the runner system and the molded part. The location and size of the gate is integral to the molding process.

Appropriate tolerances. A part with too tight of a tolerance can lead to loss of performance or even part failure. A team skilled on advanced manufacturing technologies can advise on the best ways to safely and effectively reach exact specifications.

Many factors come into play with tolerance, including materials, part complexity, tooling, and of course the injection molding process. A tight tolerance part for injection molding is plus or minus two thousandth of an inch. Starting with a good part design will ensure your tight tolerances.

If you have a tight tolerance chart, look at using low shrink rate materials such as ABS and polycarbonate materials, which have a low shrink rate. Thicker walls produce different shrink rates depending on the material, making repeatability difficult.

Higher shrink rate materials are going to be materials like nylons, unfilled nylons, polyethylenes, and polypropylenes.

Avoid tight tolerance areas around the alignment of mold halves, the parting line, or in moving mold components such as slides. If you have two parts coming together, such as in a housing, you may want to do a beauty reveal, where you can get away with hiding the mismatch.

6) Ribs. Ribs are often used for structural reinforcement. They allow for greater strength and stiffness in parts without the need to increase wall thickness.

As a general rule, design ribs as approximately 60% of your nominal wall, or whatever the wall that the rib is joining, to minimize risk of sink. Glossy materials require a thinner rib, typically about 40% of the wall thickness. Thin ribs may be more difficult to fill in, especially once you start adding draft to them.

A proper rib design involves five parameters:

–Thickness, this affects cooling rate and degree of shrinkage, which may cause warp.

–The height of the ribs should not exceed three times the rib base thickness.

–Location. Ribs added to uncritical areas can actually reduce impact resistance.

–Quantity. It’s easier to add ribs than move them, so they should be used sparingly and as needed.

— Moldability. Thin ribs can be difficult to fill. A good check is to request a mold flow and a manufacturability analysis through your injection molding provider.

7) Bosses are used for locating, mounting, and assembly. Wall thickness and height are the biggest factors to consider. Wall thickness around a boss design feature should be 60% of the nominal thickness, similar to ribbing.

If a nominal part thickness is greater than one-eighth, the boss wall thickness should be around 40% the nominal wall. The height of the boss will also have a role. As a general rule, the boss height should be no more than two and a half times the diameter of the hole on the boss.

8) Reduce undercuts. An undercut is any indentation or protrusion that prohibits the ejection of a part from a mold. Most commonly, it’s called an undercut, internal, external, or inaction. Undercuts typically increase mold complexity and can lead to higher mold construction costs. Use creativity and design them in a way where actions won’t be needed.

9) Corners and transitions tie into wall thickness. Any sharp corners can cause molded in stress, just from the resin flow.

Minimize the stress by using rounded corners, adding rads on inside corners, outside corners, and trying to maintain a consistent wall thickness.

10) Thick and thin transitions. Design these as smoothly as possible. Try to avoid steps; use a ramp to improve the flow of material through your part.

Follow these best practices in the following order to ensure an easy, cost effective molded part: materials, wall thickness, tolerances, draft, ribs, bosses, undercuts and corners, and transitions.

Successful plastic mold building often requires multiple iterations of part design and mold modification to reach a successful outcome. Our engineers review your 3-D drawings carefully for accuracy and correct any design issues before we start. This essential first step helps us determine what’s required to achieve molding success.

We also use computer simulations of the mold making process to identify unforeseen technical roadblocks to successful molding. Finding these issues right away reduces the number of iterations required to reach satisfactory part geometries, thereby reducing the time and cost of manufacturing your products.

The success and precision of a part depends on the quality of its mold, but building a reliable, long-lasting tool can take a considerable amount of time — and requires a great deal of accuracy. Also, molds are often one the largest capital investments in a project, so it’s critical that tooling is built right the first time around. This is particularly important in high-volume injection molding projects, where molds can be extremely complex.

Below are some important parameters to keep in mind when building a mold to ensure optimal quality and reliability.

What Makes a Good Mold?

A high-quality, precision-engineered mold that is built to last can be an excellent investment for your company. The best plastic injection molds feature all of the following characteristics:

Good design and engineering

High-quality stainless steel mold bases and cavities for optimal performance and durability

Manufactured on modern equipment with the capability for precise machining

Accurately crafted with attention to high standards and tight tolerances

To create a mold, we reverse engineer a design from a supplied part or create a mold based on the customer’s drawing or CAD file. To craft the tool, then utilizes EDM equipment, CNC mills, lathes, and grinding machinery. Many mold designers started out as toolmakers, so they fully understand the intricacies of the process, from start to finish.

The most common reason for companies using custom injection moulding manufacturing is to cut costs; however, if your company is considering outsourcing manufacturing, you need to determine what your goals are:

Are you interested in reducing costs; Resources can be reallocated; or Production should be increased.

Those who support outsourcing custom injection moulding believe that the tactic encourages businesses to allocate resources where they will be most productive, as well as helping maintain free markets on a global scale.

Those who oppose it, however, believe it destroys local job opportunities, particularly in industries like manufacturing and textiles. As we discuss manufacturing companies that outsource, we’ll dig deeper into this.

As a starting point, let’s look at how manufacturing can be outsourced.

When deciding how to outsource injection moulding services, what exactly is he suggesting someone be on the lookout for?

1. Keep Track Of Injection Moulding

Be vigilant over the custom injection moulding you outsource. You need a hawk’s eye. A reasonable way to minimize costs is to consider the entire workflow of a product, not just one part of it (especially when dealing with sub-assemblies). The bottom line is that strategically outsourcing production can be more cost-effective if the overall workflow has been taken into account rather than trying to minimize costs in one area.

2. There Is No Perfect Custom Injection Moulding

Outsourcing custom injection moulding won’t guarantee perfect efficiency. It is not worth the time.

3. Stay Focused But Do Not Take On Too Much

Calculate the minimum injection moulding volume that can be retained in-house so you can generate enough cash for future product development. You should not just focus on reducing costs. Outsourcing custom injection moulding can certainly be viewed as a goal, but the primary reason you should do it is that the contractor has a better facility than yours.

4. Keep Stock

Keeping some injection moulding in-house is a good idea. It would be better if you outsourced some production, but brought in people with expertise, or people you can train, to make your products, so you have the expertise to solve any problems that might arise.

5. Cost Increases Elsewhere

You should always keep in mind that outsourcing custom injection moulding will result in longer manufacturing lead times and increased transport costs. Take note when you outsource manufacturing.

6. Early Tasks Require Precision

Find ways to reduce the size of the tasks in the initial stages of injection moulding production.

7. Do Not Copy Other Businesses

You may not be able to save money using the same cost-saving techniques employed by other manufacturers that outsource. Create a business model that suits your needs.

8. Outsourcing Injection Moulding Is Not The Solution For Everything

You should not outsource 100% of your manufacturing to save money or scale your business down. Your company will be dependent on manufacturing companies that outsource and you will be forced to give up irreplaceable skills.

9. Become A Better Listener And Learner

Don’t hesitate to take advice on how to reduce costs from your employees or from other manufacturers in your market! An internal consultant will have a better understanding of how your business will function than an external consultant.

You might think, “Well, that’s all fine and dandy.”However, how do I find an injection moulding manufacturer I can trust?”

Before outsourcing manufacturing, you must do your research since choosing the wrong company can be very costly.

China mold makers are arguably the best in the manufacturing industry. As a powerhouse in the world of plastic, Chinese mold manufacturers can provide your company extensive knowledge and expertise when it comes to plastic injection molding. This factor should result to having better quality molds which will eventually be evident in your plastic products. The overall efficiency of the manufacturing process will not only impact your production but your entire business operation.

Injection molding is a complex process which you cannot learn overnight. Despite having the internet and all of these resources we have in the present day, experience is not something which you can simply preach. This is the biggest advantage of Chinese mold makers who have been working on plastic injection molding for decades and as companies solely dedicated in injection mold manufacturing. They are also up to date with research and development on this particular field.

Mold manufacturers in China also have the privilege to resources such as QA certifications, proper training, QA tools and practices symposiums which are very common in China in support of their dominance in the plastic manufacturing industry. All these resources give their employees an advantage and be a step ahead compared to other countries when it comes to injection mold manufacturing and other aspects of plastic manufacturing.

Numerous studies on successful China injection molding outsourcing projects have revealed that strong working chemistry and relationships between colleagues are crucial to the success of injection molding outsourcing projects.

Plan Your Project Scope And Timeline

Be clear about what you want to achieve before you begin the work. Provide accurate, complete information in advance so your Chinese injection molding service providers can quote you realistic prices. Please let injection molding vendors know as much information as possible regarding the work to be completed.

Make sure your schedule requirements are realistic and clear, as your schedule can drastically affect the project’s cost.

Choose The Right Chinese Injection Molding Experts

Be sure your outsourcing partner has the right experience with your type of project. Overseas injection molding development is especially complicated, so you have to hire a specialist.

Try To Think Beyond Price.

Experiential outsource buyers who assess hundreds of proposals are usually unanimous in their recommendation to disregard both the competitor’s lowest and highest bid.

Those buyers who are the most successful with their Chinese injection molding companies feel the provider offered a good value for their money while providing quality results.

Don’t Take The Portfolio Lightly

Examine the previous injection molding work done by the vendor. Even if your Chinese injection molding vendor’s portfolio, references, and previous work experience do not demonstrate that they are competent, they might still be able to create a mock-up or outline a simple action plan.

Chinese injection molding vendors who are intensely interested in earning your business may be able to provide you with a rough idea of what they will offer.

Feel free to ask for a mock-up, but do not demand that a vendor provide finished work on your spec. No qualified professional will agree to work for free.

Start With Small

Engage the first service provider for a small and relatively straightforward job, then move on to larger, more complex injection molding jobs as time goes on.

If you do so, you will gain a better understanding of the offerings and capabilities of the provider before entrusting your “mission-critical” project to them.

Build Project Milestones Into Payment

Similarly, just as it is imperative to make sure that you outline a clear timetable for your outsourced injection molding project, it may also be helpful to set out a specific schedule of deliverables.

By scheduling regular checkpoints – in which you can review the project’s status as it progresses toward completion – it is easy to ensure that the mold makers will complete the project on schedule and of high quality. You should coordinate the vendor’s payment with these milestones.

A good rule of thumb is to fund only a small portion of the total project costs out of your own pocket and the remainder in installments over three or four milestones.

Negotiate Your Ownership As Early As Possible

If you ever outsource any tooling or injection molding work in China, it is vital to clarify who owns the work product and any significant elements thereof.

If you intend to develop a custom injection molding part for your personal use, there will be substantial differences from the development of plastic parts you intend to resell.

Support After The Delivery

It is good practice to include a warranty clause in technology projects so that you can ensure that the Chinese injection molding vendor will continue to support after the injection molding project is completed.

To negotiate a support clause, it is much easier to negotiate it before the service provider starts work rather than after the injection molding project has been completed.

Prepare For Culture Clashes

An injection molding outsourcing from China involves both cultures, and these differences must be embraced and bridged. It would be best to organize social events between the companies to better understand the cultures’ differences.

Engineering services notably reduces time‐to‐market, optimizes costs, and ensures quality. they should provide the knowledge and experience that create stellar solutions ‐ from early stage product design to a successful manufacturing process. mold engineers have experience working with a vast array of industries ranging from Medical Devices to High PrecisionCNC, Electronic PCBA and much more. A local Project Manager had better being assigned to each project, responsible for all communications with you while monitoring quality requirements on site.

their Design and Engineering Services Include:

Conceptual Design, Mechanical Engineering Design, CAD Modeling and Detailing, Simulations, Analysis and Prototyping Design for Assembly, Design of Bill of Materials (BOM), Reverse Engineering and Project Management, Weekly status updates including alerts to any production problems and/or shipping delays, QC report before shipping

If you’re shipping the mold overseas, you will take possession of the mold, but still there are areas you need to be very clear on with your Chinese mold makers, like complete ownership, IP, etc. However, if you’re producing with a factory in China it is critical you make sure that the mold makers understand that YOU own the physical mold.

Firstly – you need to make it clear to the manufacturer/factory in China can only use the molds for producing your products and that they can’t produce any products for a third party using your mold or mold designs.

Secondly – you need to make sure that if you want to move your mold at any point in time to a different factory, that the receiving facility will have the right to take possession of the molds and that you can freely move them to a new location.

Chinese manufacturers have a strong incentive to keep your molds and prevent foreign buyers from moving to a new location or factory. In a lot of cases, the mold embodies most or all of the IP in the product.

With some products, the interior mechanism is based entirely on open source hardware. The exterior enclosure around the mechanism is, therefore, the primary protectable IP for the product. The intellectual property lies entirely in the molds used to manufacture the product case. The outside “appearance” of the enclosure then becomes the ID of the product, and if that “appearance” isn’t protected, you will own NOTHING at all in the IP of the product.

Without that IP in the mold protected, the Chinese factories can copy the product as they see fit.

On the other hand, in some products, the form embodies in the mold holds the entire value of the product. One example could be that of a single part used in an extremely complex engine, like that of a jet engine. After all the designing, engineering and testing is complete what will you be left with? A single part produced by casting into single or multiple molds.

In this instance, the molds embody the entire intellectual property for that part. In short, whoever owns or controls the IP in the molds is essentially in complete control of the product, so you can see why this is a crucial aspect of mold making in China.

Many successful custom manufacturers of molded plastic products began with an innovative design or a new invention. Naturally, they kept the secret to themselves and produced their new product entirely in-house.

Later, with patents in place and a growing customer base, they found that their R&D suffered. Too much was going into the wrong areas and that spirit of invention and creativity was losing out to the day-to-day operations.

Initially, it might be painful to send work to an offshore supplier, in the long run it often benefits for the entire company and it’s employees. True, this “shedding” process is temporarily disruptive, but when properly managed has positive effects.

Often, an unexpected side effect of offshore outsourcing is the new exposure to different ideas and ways of doing things. This can lead to new areas of R. Now, with a more agile company and engineering department, these ideas can be developed with fewer distractions. The international marketplace is growing exponentially and new products are constantly being introduced in previously untapped markets.

This represents a huge opportunity for custom manufacturer’s who are in a position to develop and market new products. The Brookings Institute has an informative paper on the regulations surrounding offshore outsourcing.

Outsourcing helps to expand into new markets

It often happens that new opportunities present themselves as companies venture into the unknown of offshore outsourcing. Several major injection molders took steps to be in a position to benefit from the global economy by making alliances with foreign companies.

It took quite a bit of doing, but the floodgates opened for them and work just keeps coming.

Some global companies require an offshore presence in order to even do business with them. The world is the marketplace and boundaries are quickly disappearing.

Mold engineering can be broken into three steps:

1. Product Design

Determining product objectives such as function, aesthetics, assembly, etc., and the requirements for accomplishing the objectives. A team of engineers specially trained in advanced methodologies such as Design for Manufacturing ability (DfM) is assembled to identify and possibly improve upon solutions to meet the particular project requirements — including the selection of materials for the final complex injection molded part and the tool.

2. Mold Design

Like product design, a thoughtful approach to tooling proves valuable. In addition to choosing the appropriate material for tool construction — hardened steel, pre-hardened steel, or aluminum — designing for proper gate location, draft, etc., is necessary to prevent costly project missteps.

3. Manufacturing

Production is the obvious goal of the step-by-step injection molding process. Achieving successful outcomes brings together the product and tool designs with resins that deliver to project needs (such as strength, heat tolerances, sterility, etc.) and mold ability requirements including tight tolerances, uniform wall thickness, heating, cooling, and consistent repeatable cycling.

Manufacturing plastic injection molded components in-house as part of a customer’s end product can prove to be a significant challenge from an efficiency, quality, and cost perspective. Many companies have seen the relative ease with outsourcing and have decided to incorporate that process into their business model.

With the continuous maturity of ERP software, the accuracy of mold engineering will become better and better

A high-quality, precision-engineered mold that is built to last can be an excellent investment for your company. The best plastic injection molds feature all of the following characteristics:

Good design and engineering

High-quality stainless steel mold bases and cavities for optimal performance and durability

Manufactured on modern equipment with the capability for precise machining

Accurately crafted with attention to high standards and tight tolerances

The success and precision of a part depends on the quality of its mold, but building a reliable, long-lasting tool can take a considerable amount of time — and requires a great deal of accuracy. Also, molds are often one the largest capital investments in a project, so it’s critical that tooling is built right the first time around. This is particularly important in high-volume injection molding projects, where molds can be extremely complex.

The greatest value to customers may not be in the upfront savings they enjoy, but in the enduring costs they avoid. By utilizing a single plastics manufacturer, customers avoid the cost of duplicating unique and expensive tooling. And they eliminate the learning curve and risks associated with manufacturing complex parts using multiple suppliers.

during running the whole mold engineering, One of the easier problems to identify is a dimensional issue. Remaining steel-safe allows you to make dimensional adjustments on critical dimensions without welding. Also, a capability study is necessary to determine the final changes required to mold.

The first step in assessing a mold problem is quite simple, but also very effective: Place the tool into the molding process for trial-and-error testing. Once you witness the process, it becomes easy to rule out some probable causes of a problem and begin searching for the real issue.

If you’re beginning a new project that will need injection molding, you’re going to need an experienced CAD service to help create the most effective and cost-efficient designs possible. When you’re ready to find an injection molding engineer or designer, make the process as simple as possible for you.

A high-quality, precision-engineered mold that is built to last can be an excellent investment for your company. The best plastic injection molds feature all of the following characteristics:

Good design and engineering

High-quality stainless steel mold bases and cavities for optimal performance and durability

Manufactured on modern equipment with the capability for precise machining

Accurately crafted with attention to high standards and tight tolerances

Injection molds for plastic parts are complex works of art. The creative aspects of moldmaking require dedicated engineers who have the experience to blend imaginative design with part manufacturability. It requires an exceedingly precise process. Mold designers execute certain seemingly tedious, but critical tasks prior to performing the creative work that defines a product. In moldmaking, most problems occur at this legwork stage.

My name is Mohammed Abdul-Razak Kuntey from Accra-Ghana,a graduate who want to take advantage of plastic waste in my country to create a business of my own,just love your services.

I just asked a company to manufacture a machine that can assist me schrude and melt the plastics to remold it to other products.

May you please assist me by producing the following handmade mold for my proposed products:

1,Armchair without legs

2,Toilet bowl with water tank

3, wash basing

Material to use:

1,Plastics

2,Sand/Clay

Thank you

Hi Mohammed:

please Email more details about your products to us, including design data or design drawing, so that we know how to do

When designing a part for injection molding, there are three initial aspects we look into: tolerance, draft angles, and undercuts. Tolerance enables multiple parts to fit together without exerting too much force on one another. Draft angles enable the plastic part to be pulled apart from the mold tooling with limited friction. Undercuts are features that prevent a plastic part from exiting the injection mold tooling. Undercuts can get quite complicated, and for cost-effectiveness, designers and engineers are encouraged to design out undercuts when possible to minimize the complexity of the injection mold tooling.

Good DFM as it relates to injection molding goes beyond checking for tolerances, undercuts and draft angles. Throughout the design process, engineers should keep in mind to constantly communicate and document project changes in a version control document or software. Product design is a collection of iterative changes, so keeping track of revisions makes it easier for engineers and clients to refer back to past designs. A good engineer not only meets all of the client’s specifications, but they aid in cutting costs, simplifying design while keeping the product’s purpose and minimizing production time — all of which will lead to a smooth and hassle-free manufacturing process.

Injection molds for plastic parts are complex works of art. The creative aspects of moldmaking require dedicated engineers who have the experience to blend imaginative design with part manufacturability. It requires an exceedingly precise process. Mold designers execute certain seemingly tedious, but critical tasks prior to performing the creative work that defines a product. In moldmaking, most problems occur at this legwork stage.

As a short-run injection molder for leading OEMs, Donnelly Custom Manufacturing (Alexandria, MN) continually strives to focus efforts where they will have the greatest impact on quality and productivity. In injection molding, rigorous dedication to engineering helps solve many injection molding problems—sometimes before they arise and steel is cut.

What sets you apart from other tool makers is your ability to deliver custom tooling solutions for your customers based on their specific needs. For example, the quality deliverables, budget, and time constraints of a short-run point of purchase display product mold could be very different from that of a medical product mold. As a diversified company servicing several industries, you are in the unique technology of being able to help your customers make the right decisions on the critical considerations of tooling design for their specific applications. thank you so much for help us a lot

Hi Douglas:

Thank you very much for your praise, your satisfaction is very important to us

From initial design, to prototyping, to the finished product, Creative Mechanisms can help turn your idea into reality with cost effective injection molding in mind. this kind of company should be a design and engineering firm with experience designing products across multiple industries, and build a strategic network of injection molding companies to finish the process.

When you outsource the work of plastic mold designing to professional, not only are you increasing your profitability by eliminating your equipment costs – you’ll have a design that is capable of being manufactured and reproduced. Compared to a professionally crafted plastic mold, DIY plastic molds are far more likely to havestructural inconsistencies or lack of appropriate material thickness, both of which will result in longer cycle times and quality problems later on down the road.

Choose an injection molding and tooling partner with design expertise, and involve them in product development as soon as possible. When engaged early, your supplier can offer suggestions to improve part design, mold design, and cost. he should provide in-house program management, including design experts who will consult with your team on the manufacturability of your parts. they first ensure that the design is compatible with your assembly or applications and then find ways to make your parts faster and at a lower cost.

In fact, you are the project broker we are talking about. If our mold are made in China, our broker can handle many problems. If you are looking for a direct supplier, you will have to face many problems that you are not familiar with. . You can easily work with design companies. However, they are not very familiar with the manufacturer, which means that you and your company still have a considerable burden.

I highly recommend First-rate mold solution company, if you are looking for mold broker in china

The most important part of the team providing mold engineering services is the technical level, the rich experience in the mold industry and the familiarity with the products, as well as the good communication skills and mature control processes. I recommend the mold engineering team of First-rate mold company. They really can do a good job!

Internet technology greatly helps the operation of offshore mould project

With the development of Internet technology and artificial intelligence technology, offshore mold project will be more and more easy to complete

With the development of Internet technology, molds can be easily made anywhere in the world

The management of mold project of many mold companies is quite chaotic, it seems that your company is doing well in this respect

In fact, in many cases, for offshore mold project, a lot of factories processing technology can not absolutely meet customer requirements, our project engineer should learn how to communicate with customers and to guide our designer

The core of mould project management is that the mould made by the manufacturer fully meets the requirements of customers

I think as a mould project engineer, you can know many new mold structures, but your job limits your understanding, a lot of the details for this structure are not known, because this is not your design

We call the mold project management as the mold engineering, it needs a team to work together to do a good job

With the development of Internet technology and artificial intelligence technology, mould manufacturing will become easier and easier in the future.

Yes, you are only half right, because a qualified mold project engineer needs a strong comprehensive ability. Experience with mold design alone is not enough.

Many of them were a mold designer before becoming a mold project engineer, but some of them didn’t do very well.

In fact, as a mold project engineer, the accurate description should be understood in every step of the mold project, but not proficient, know how to judge and deal with the problem

Mastering a foreign language is also a basic requirement for a mold project engineer.

The project engineer should have experience in mold design and actual manufacturing experience.

The management of data and information is very important in mold project operation.

As a mold project engineer, if your mold project comes from Europe and America, you must have a good understanding of the design and production standards of European and American moulds.

In the operation of the mold project, quality and cost control are particularly important.

In my opinion, the work of the project engineer is very complicated. I don’t like it.

In any case, it is important to communicate with customers in mold project operation.

As an offshore mould project engineer, his professional foreign language proficiency is very important. Because communication is important.

In my opinion, the mold project engineer needs the comprehensive ability, I mean he should have a strong ability to control the design, manufacture, confirmation, purchase, transportation and so on.

It seems to me that if a good mold designer works a few years as a project engineer, his skill level will drop a lot.

It is much more difficult to be an excellent mold project engineer than to be a good mold designer.

I feel your mold project management process is not bad, feel free to communicate.

I used to be a mold designer, now I am a mold project engineer, I feel that my knowledge is insufficient to support my work, I need to study hard.

Hi guy I can understand what you are talking about, I am a mold project engineer, Every day I have a mountain of work to do in order to do a good mold

I think the project engineer is much more tired than the mold designer, because he wants to control the whole situation.

Now there are some moulds from Germany that are being done in our mould workshop. I find that it is very important to communicate with customers as a project engineer.

The project engineer needs strong professional ability and rich practical experience when running every offshore mold project.

Hi we also operate offshore mold project, maybe we can discuss something together :-)

Hi you are welcome any time :-)

our mold project management has something different with yours, i think we can discuss

offshore mold project management need a set of carefully controlled processes.

Our company will provide this kind of offshore mould project service in 2018. Your article is worthy of our study.

With the development of Internet technology, the offshore mould project will become more and more popular, because the world is getting smaller and smaller.

I work as a mold project engineer in a mold company. After seeing your process, I think we can communicate this problem with you.

hi isabell you are welcome any time!

your project management process is very professional, it is worth studying

2018 working schedule has stared, maybe your project management process will star :-)

offshore mold project management is not easy to run, because of too many unexpected issues

offshore mold project running is a prelude to the globalization of manufacturing

Hi we do the same thing at different country, maybe we could discuss :-)

Hi lucy, we would like to discuss it with you, you are welcome any time

As the mould manufacturer of offshore mould, I would like to say that your process is not bad. We can communicate with each other when we feel free

No problem! you are welcome any time

we will start some new projects, they all need to make molds, maybe we will have a chance to do it together:-)

thanks! we would like to have a try

project management process is very important, it seems that you have a good process.

Hey! i don’t know why I like to read your blog,Maybe it is really magical :-)

I really appreciate your offshore mold project management process. I believe that you can do a good job

i still want to say in mold project management, we can discuss here, i wish more mold project engineer join in

hi clay, you are welcome any time

actually different mold company has different project management process, but totally The results are the same

I am a mold project engineer, it seems that I could learn something useful from your process

I think your project management can help you to do a good job!

offshore mold project management is not easy to do

I think a qualified mold project engineer needs to learn a lot of knowledge

Yes! The mold project engineer needs comprehensive ability

I think your project management process is excellent

your mold project management system is very suitable for offshore mold project running

Project management is a systematic project,detail is very important

as a mold project engineer, I think your project management is very good.

it seems that you have good experience in mold project management

a powerful project management system is the guarantee of project completion

project management system need to control a lot of details

as for this topic, we can discuss

Timely communication is very important in offshore project management,Because of the distance and time difference

as for running offshore mold project, maybe some experience from your process can be borrowed

your project management system is very perfect, I believe you can do a good job for our products, I will recommend your team to our company

hi thank you so much! we will try our best to help you if we have this chance

now we do the same thing with yours, but something different in offshore mold project management process

internet technology improved offshore mold project management, I mean it is very easy to do it

With the development of Internet technology, offshore mould projects will become more and more popular,your system should be imporved

I am a mold project engineer, I like to read your blog, it is very helpful for my work

I am a mold project engineer, after reading your process, it seems that you could do a good job

offshore mold project management is not easy to do

your project management is very good!

mold project management is not easy to do well, because there are so many uncertain factors

as a mold maker,I appreciate your sharing

Detail management determines the success or failure of a project

your mould management process is very good. I believe you can do a good job!

we are a company which has similar business with yours,I appreciate your management process

as a mold project engineer, I want to say it is not easy to do a good job in project management

I am a mold project engineer, after reading your process, I want to say your process is perfect.

especially for mold project management, the process is Very complicated,Because there are too much thing you never thought would happen

I really like to read your blog, because I can learn a lot from it. thanks for sharing

your process about mold project management is very good. I am sure you are a professional company

after reading your process, I would like to discuss with you here

I am a mold project engineer, I understood your process

Hi I love to read your blog. it is very good

I really want to have a discussion here to discuss this issue

Hi I am an injection mold project engineer, after reading this article, I want to discuss with you about this issue

Hi Sheldon, no problem, you are welcome anytime.At the same time, you can also publish some articles on our website to let everybody to learn

project management is not easy to do, because too much need to be considered

good process! thanks for sharing

your experience will benefit your customers

we should learn each other,Maybe we will get more knowledge,because Live and learn

this is a good process in running a mold project

in my opinion, your process should be improved, what do you think?

welcome to discuss anything about this issue

the process of your project management is for offshore mold project

it seems that you have a good process in offshore mold project management

it seems that you can do a good job for us:-)

we are waiting for your project:-)

good experience, good process!

good experience should be shared, you did a good job! thanks!

you can do a good job for your customers because of your good management system

I’m truly enjoying the design and layout of your site. in project management, I want to say you really have some experience in offshore mold project

your blog is very excellent, every professional mold engineer and designer can benefit from it

your project management process is very good, it is worth learning

your process is very good

for offshore mold project, the project management process is very important, it seems that you did a good job!

I agree your process, you can do a good job in running offshore mold project

in germany, I believe that many companies would like to send their new projects to you, because you can do a good job!

actually running offshore mold project is not easy, because too much need to be considered

I appreciate your mould management process

I think we can discuss this issue when we feel free

welcome to discuss

Hi we do the same job! it seems that you do it better, we should learn from you:-)

mold project management, especially for offshore mold project management is not easy to be down, it seems that you have some good experience

I think we should learn from you, in this field, you did a good job!

Hi thanks for sharing your experience on mold project management

I knew there are many companies like this in china.

it seems that offshore mold project is a good opportunity for some professional mold companies

I agree your process, but in my opinion, it is not easy to do a good job in running mold project.

Hi we do the same thing in the same field, we can discuss on this topic

this is a good mold project management system

actually it is not easy to do a good job in offshore mold project, it seems that you can do it

your process on offshore mold project management is very good.

after reading your process about mold project management, I believe we can try to build a business relationship in 2017,I will discuss it with you after christmas holiday

I like your project management process, it is very good

it seems that you have some experience on project management

your experience is worth learning

when we feel free we should discuss this issue

mold project management is not easy to do

your experience on project management is very good, it is worth studying

I believe that you have some experience on offshore mold project manangement

good experience! thanks for sharing

mold project management is a big topic, especially for offshore mold project

it seems that you have some experience in offshore mold project management

it is not easy to make a perfect mold project management, it seems that you did a good job!

The same thing must follow the same rules

your offshore mold project management process is very good! I will study it

Thanks for sharing your project management process

Correct and efficient project management processes is very important

our new Bluetooth phone will need your service, are you interested in it?

please contact us by Email, maybe that is a good chance

I agree your project management process, it is very strict

I am also a mold project engineer, I will discuss this issue with you by Email, you can share our discussion here

I am a mold project engineer, after reading your process, I think we can discuss it when I feel free.

Thanks for sharing your Project Management process, I think it is worth studying

project management system is very important for offshore project

this is a big topic, but I believe that you can do a good job for your customer

Well written article. It will be useful to any professional guys, including me. I cannot wait to read more posts.

good mold project management, we will learn from you

I really like your blog, it is very professional, your management system will benefit our projects.

It’s hard to find a website like this, now I have luck to get one and will recommend to other professional guys

I am a mold project engineer, I think your mould management system is very good

mold project managemment is an art!

mold project, especially for offshore mold project, a good management is very important for both side

In practice, there are a lot of unexpected problems, So our mold project engineers need to master the process

in order to become an excellent mold project engineer, first of all, he(she) must be an excellent mold designer and mold engineer

good project management system! it is worth studying

I learned something new form your project management system. thanks!

I am going to discuss with you, because I have some point there.

your process is very good, but I still want to discuss with you!

if you have any question or any new idea, please feel free to contact us

I will recommend your blog to my friends, they would like it I think

Hi, after reading your process, I want to tell our engineers to discuss this topic here

I will contact you to discuss this topic when I feel free

Hey there, You have done a fantastic job. I will certainly recommend to my friends. I am sure they’ll be benefited from this

site.

I think in the offshore mold project, your process is worth studying

With the improvement of automation degree, the requirement of mould project engineer is becoming more and more high

after reading this post, our project engineers want to discuss with you, maybe we will have a discussion here or we will contact you, because they have some different experience.

no problem! we are waiting for you, if you have any question or any experience need to share, please feel free to contact us! thank you in advance

I believe that you have got some experiences in offshore mould project management.

your management system is worth studying, maybe it will help us to improve our system.

your experience on this field is very excellent, thanks for sharing.

we should discuss this topic each other

you have done a Great job in this field! maybe we could discuss each other if it is possible

yes! we think so! we are waiting for you here

It’s enormous that I am learning something useful from your blog, thanks!

project management is a Systems engineering, it decides your mould’s quality and mold making cycle

project management is a big topic for our mold industry, we need to discuss more.

your experience on mold project management is very helpful for us. thanks for your sharing

I learned something useful from it, thanks!

I think your experience is very helpful for me.

at least, in my opinion, you found a good system for mold project management

your experience on mold project management is worth our learning

I think we can discuss on this issue

your project management system is very good!

Excellent process. I certainly believe that you can do a good job

your project management process is very professional

I appreciate your concept of project management

your idea is correct! you can do a good job

a good project management system is very important

I believe that you can do a good job for your customers

on this topic, we can discuss, maybe it will benefit each other

I can understead The importance of project management, you do a good job in it

we do the same thing with yours, maybe we could discuss on this issue

your project management process is very good

your project management system is worth learning.

especially for offshore project, your system is very useful

a good project management system will help you to do a good job!

a clear project management system, you can do a good job for your customers

I appreciate your business philosophy

for offshore project, a good management system is very important

Thanks for sharing your thoughts about mold project management and mold manufacturing.

Regards

project management is a systematic work。

You’ve made a really good project manangement system there. I checked on the web for more information about the issue and found most individuals will go along with your view.

Excellent article. I certainly appreciate your sharing. Keep it up!

your project management is very professional

I think you are an expert in offshore project management,we should learn from you

Hi, Neat post. your project management system is very reasonable. it is worth to learn

I think we can discuss each other, Each company has it’s special process

I will recommend this company to our customers, it is very professional

Thank you for your encouragement and support

in order to do a good Offshore project, you must have a good project management system

thank you for sharing your project management process

Many mould companies don’t realize the importance of project management

this is a big problem, different customer always requires something special

you have a very good management system in managing offshore project

for a mold project mananagement, project engineers play an important role

a perfect mold manufacturing needs a perfect project management

your experience is worth studying

in mould project management, experience is very important

I am a mold project engineer, I understand your process very well, good job!

we would like to exchange some experiences about this topic.

We are willing to exchange

we will study your project management system carefully, maybe we could get something useful

the cost of project management should be considered during running every project.

Project engineer needs strong comprehensive quality

your experience is very fine

your experience in project management is worth studying

The essence of project management is to ensure high production efficiency

your project management system is very good, I think we should learn from you

your project management system is successful, we should learn from you

a perfect project management is very important for our customers

Only a good management team can do a good job

Some mold companies ignore project management

Due to the particularity of mould making, project management is very important

Project management is a quality control process

An excellent mold project engineer need a lot of professional knowledge and practical experience